Method for preparing high-purity poliumoside

A high-purity technology of chrysoside, applied in the field of natural medicinal chemistry, can solve the problems of large amount of solvent and small preparation amount, and achieve the effects of large preparation amount, high degree of industrialization and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

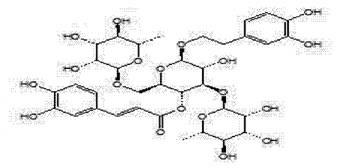

Image

Examples

Embodiment 1

[0016] Pulverize the medicinal material of Guangdong Zizhu, take 2kg and add 5 times the amount of 70% acetone solution for ultrasonic extraction (200w, 40KHz) 3 times, 30 minutes each time, the extract is filtered to recover the solvent, the concentrated solution is added to the same volume of water-saturated n-butanol for extraction 2 The second time, the extract was perfused into a short column of alumina (500g of neutral alumina, with a particle size of 120-200 mesh), and the column solution was concentrated under reduced pressure to obtain 35g of extract. Chloroform, methanol, isopropanol, and aqueous solution are mixed at a ratio of 3:1:0.5:5. After fully stratified, remove the lower phase and fill the high-speed countercurrent chromatography column, start the host, adjust the speed to 700rpm, and pump the upper phase as the mobile phase at the same time. After dynamic balance, the flow rate was adjusted to 2ml / min, the mobile phase was dissolved and the extract was injec...

Embodiment 2

[0018] Pulverize the medicinal material of Guangdong Zizhu, take 2kg and add 5 times the amount of 50% acetone solution for ultrasonic extraction (200w, 60KHz) 3 times, 30 minutes each time, the extract is filtered to recover the solvent, and the concentrated solution is added to the equal volume of water-saturated n-butanol for extraction 2 The second time, the extract was perfused into a short column of alumina (500g of neutral alumina, particle size 120-200 mesh), and concentrated under reduced pressure to obtain 42g of extract. Chloroform, methanol, isopropanol, and aqueous solution are mixed according to the ratio of 10:4:2:15. After fully stratified, take the lower phase and fill the high-speed countercurrent chromatography column, start the host, adjust the speed to 1000rpm, and pump the upper phase as the mobile phase at the same time. After dynamic balance, the flow rate was adjusted to 3ml / min, the mobile phase was dissolved and the extract was injected with a samplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com