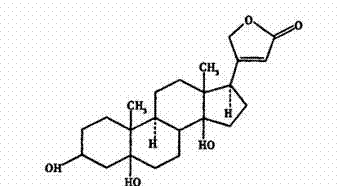

Method for preparing periplogenin through enzymatic hydrolysis

A technology of salivarius and aglycone, which is applied in the field of enzymatic hydrolysis to prepare salivarius aglycone, can solve the problems of polluted environment, environmental pollution, large sample loss, etc., and achieves the effects of high extraction efficiency, less impurity dissolution, and easy handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Grind the medicinal material of Persica cypress, take 1000g, add 8L90% methanol solution for ultrasonic extraction for 60min, filter the liquid and add 3L90% methanol for ultrasonic extraction for 30min, combine the extracts to recover methanol, add 500ml distilled water to azeotrope for 1 hour, add appropriate amount of diatomaceous earth Heat centrifugation, collect the centrifugate, adjust the pH to 4.5 with citric acid, heat to 50°C, add 1 g of helicase and incubate the enzymolysis for 32 hours, concentrate the enzymolysis solution under reduced pressure, and centrifuge to obtain 12 g of crude product. Mix chloroform, methanol, and water in a ratio of 4:3:3, take the upper phase and inject it into the chromatographic column as the stationary phase, turn on the high-speed countercurrent chromatograph, adjust the speed to 800r / min, inject the mobile phase, and after equilibrium, adjust the flow rate to 2ml / min, The crude product was dissolved in chloroform, injected, a...

Embodiment 2

[0029] Grind the medicinal material of Persica cypress, take 1000g, add 5L80% methanol solution for ultrasonic extraction for 40min, extract 3 times, combine the extracts to recover methanol, add 600ml distilled water to azeotrope for 1 hour, add appropriate amount of diatomaceous earth and centrifuge while it is hot, collect the centrifugate, hydrochloric acid Adjust the pH to 5, heat to 55° C., add 5 g of cellulase and incubate for 18 hours for enzymolysis, concentrate the enzymolysis solution under reduced pressure, and centrifuge to obtain 10 g of crude product. Mix chloroform, methanol, and water in a ratio of 4:3:3, take the upper phase and inject it into the chromatographic column as the stationary phase, turn on the high-speed countercurrent chromatograph, adjust the speed to 900r / min, inject the mobile phase, and after balancing, adjust the flow rate to 3ml / min. The crude product was dissolved in the mobile phase, injected, and the fractions were collected regularly by...

Embodiment 3

[0031] Grind the medicinal materials of Xiangjiapi, take 1000g, add 6L85% methanol solution for ultrasonic extraction for 60min, extract twice, combine the extracts to recover methanol, add 500ml distilled water to azeotrope for 1 hour, add appropriate amount of diatomaceous earth and centrifuge while it is hot, collect the centrifugate, lemon Adjust the pH to 5 with acid, heat to 50°C, add 3g of amygdalin and incubate it for 26 hours, then concentrate the enzymatic solution under reduced pressure, and centrifuge to obtain 12g of crude product. Mix chloroform, methanol, and water in a ratio of 4:3:3, take the upper phase and inject it into the chromatographic column as the stationary phase, turn on the high-speed countercurrent chromatograph, adjust the rotation speed to 1200r / min, inject the mobile phase, and after balancing, adjust the flow rate to 4ml / min. The crude product was dissolved in the mobile phase, injected, and the fractions were collected regularly by the detecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com