Alicyclic epoxy acrylate prepolymer and preparation method thereof

An epoxy acrylate and cycloaliphatic technology, which is applied in the field of UV-curable resin and its preparation, can solve problems such as limiting the application range of coatings, coating yellowing, coating weather resistance, and poor aging resistance. Good UV aging resistance, overcoming aging resistance, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (a) 0.91g4-methoxyphenol, 1.80g tetramethylammonium chloride are dissolved in 81.36g acrylic acid;

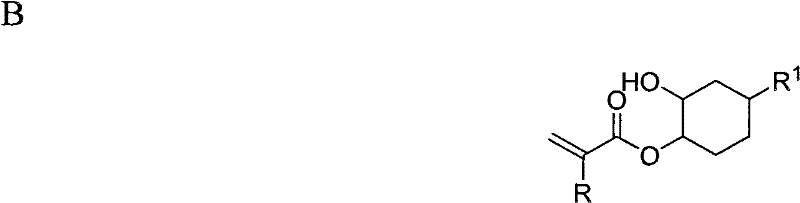

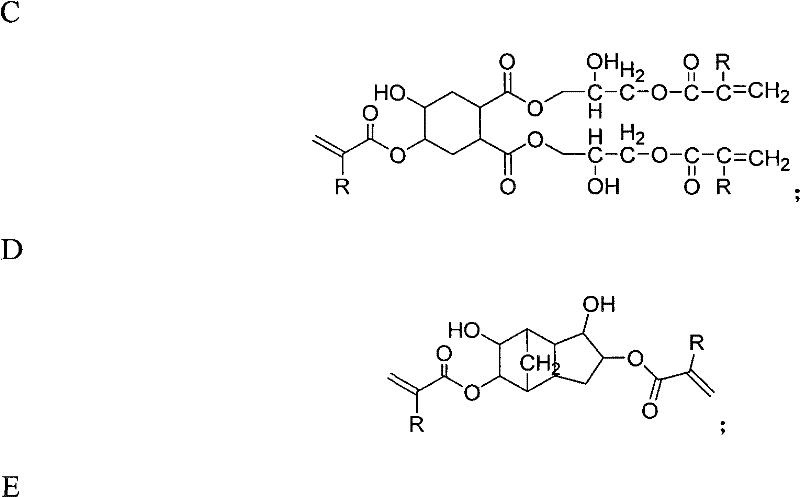

[0046] (b) Add 100.0 g of alicyclic epoxy resin to a four-necked round-bottomed flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel, protect it with nitrogen, stir and heat up to 50 ° C, and the mixture solution in (a) Transfer to constant pressure dropping funnel, drop in the flask in 60min; The structural formula of above-mentioned cycloaliphatic epoxy resin is:

[0047]

[0048] (c) The temperature of the reactants in the flask is raised to 65°C, kept for 1 hour, then raised to 75°C, kept warm for 2 hours, and finally raised to 85°C for 4 hours;

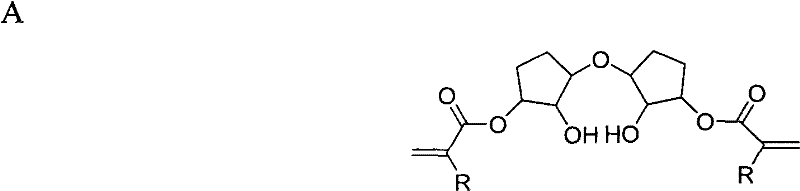

[0049] (d) Measure the acid value of the reaction solution, its acid value is 5.65mgKOH / g, stop the reaction, cool to room temperature and discharge to obtain alicyclic epoxy acrylate prepolymer 1-1, its structural formula is:

[0050]

Embodiment 2

[0052] (a) 0.79g 4-methoxyphenol, 1.58g tetramethylammonium chloride are dissolved in 57.90g acrylic acid;

[0053] (b) Add 100.0 g of alicyclic epoxy resin to a four-necked round-bottomed flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel, protect it with nitrogen, stir and heat up to 50 ° C, and the mixture solution in (a) Transfer to constant pressure dropping funnel, drop in the flask in 60min; The structural formula of above-mentioned cycloaliphatic epoxy resin is:

[0054]

[0055] (c) raising the temperature of the reactants in the flask to 65°C, insulated for 1 hour, then raised to 75°C, incubated for 2 hours, and finally raised to 80°C for 3 hours;

[0056] (d) measure the acid value of the reaction solution, its acid value is 6.38mgKOH / g, stop the reaction, cool to room temperature and discharge to obtain alicyclic epoxy acrylate prepolymer 1-2, its structural formula is:

[0057]

Embodiment 3

[0059] (a) 0.73g 4-methoxyphenol, 1.47g tetraethylammonium bromide are dissolved in 47.54g acrylic acid;

[0060] (b) Add 100.0 g of alicyclic epoxy resin to a four-necked round-bottomed flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel, protect it with nitrogen, stir and heat up to 50 ° C, and the mixture solution in (a) Transfer to constant pressure dropping funnel, drop in the flask in 60min; The structural formula of above-mentioned cycloaliphatic epoxy resin is:

[0061]

[0062] (c) raising the temperature of the reactants in the flask to 65°C, insulated for 1 hour, then raised to 75°C, incubated for 2 hours, and finally raised to 80°C for 3 hours;

[0063] (d) measure the acid value of the reaction solution, its acid value is 6.60mgKOH / g, stop the reaction, cool to room temperature and discharge to obtain alicyclic epoxy acrylate prepolymer 1-3, its structural formula is:

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com