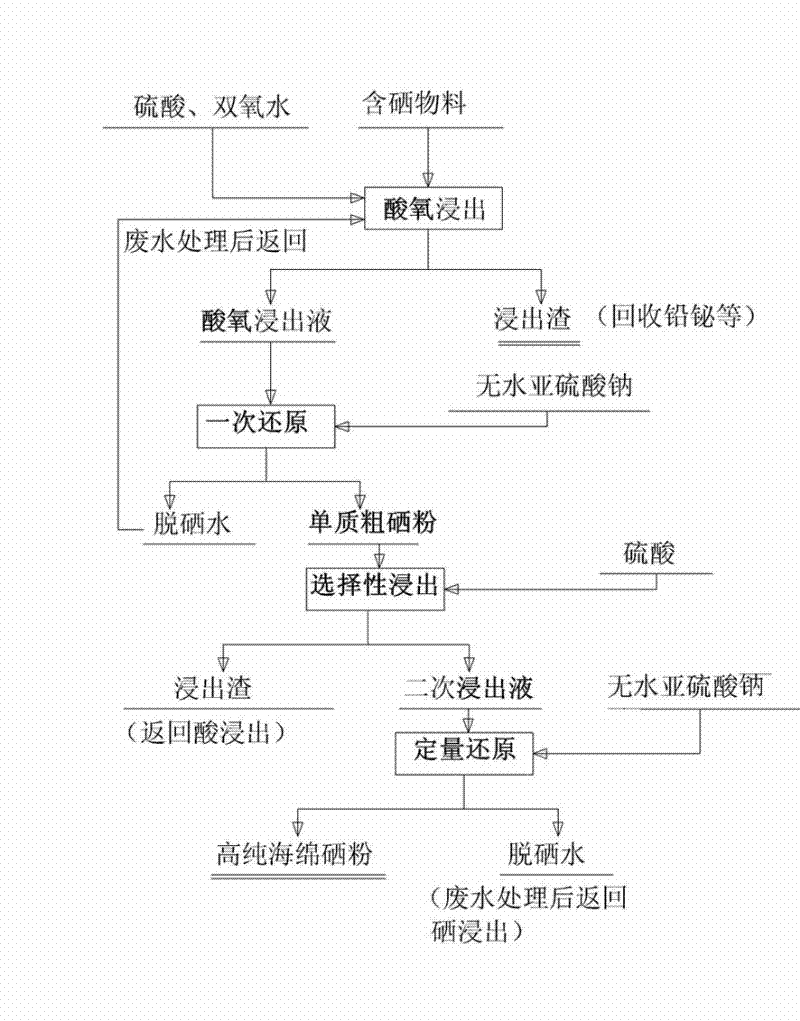

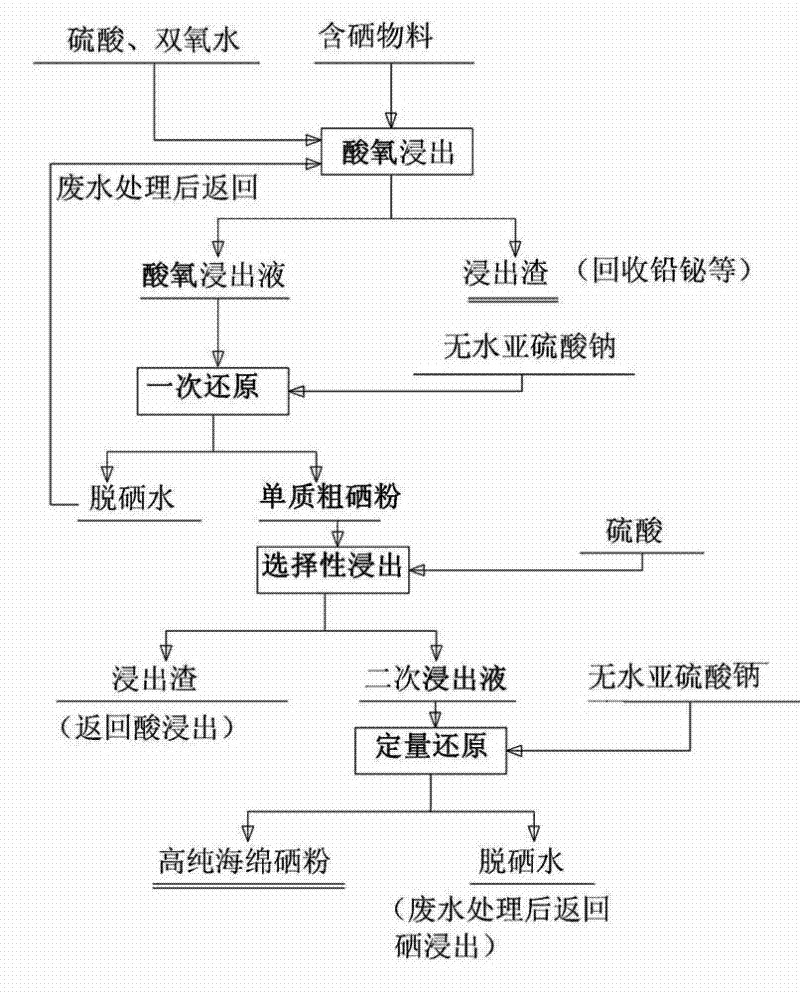

Technology for extracting selenium from low-grade selenium-containing material

A low-grade, material technology, applied in the field of metallurgical technology, can solve the problems of large environmental pollution and low recovery rate, and achieve the effects of no environmental pollution, high recovery rate and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment approach 1

[0027] (1) Take 500g of selenium-containing raw material, which contains 4.32% selenium, and grind it to 100 mesh;

[0028] (2) Add 1500g of water, 150g of sulfuric acid, and 25g of hydrogen peroxide to the selenium-containing material, heat at 90°C, stir the acid-oxygen leaching solution for 3 hours, and filter to obtain 305g of leaching residue (including 0.30% selenium), and 1520mL of acid-oxygen leaching solution ; The leaching slag is sent to pyrometallurgy to recover lead, bismuth and copper;

[0029] (3) Add 43g of anhydrous sodium sulfite to the acid oxygen leaching solution produced in the previous step, heat at 90°C, stir for 1.5 hours and then filter to obtain 22g of coarse selenium powder; return the deselenized water to acid oxygen leaching;

[0030] (4) Add 100g of water and 30g of sulfuric acid to the selenium-containing material, heat at 90°C, stir for 3 hours, and filter to obtain 1.0 g of filter residue (including 13.5% selenium), and 110mL of secondary leach...

experiment approach 2

[0033] (1) Take 10kg of selenium-containing raw material, which contains 3.92% selenium, and grind it to 100 mesh;

[0034] (2) Add 30kg of water, 3kg of sulfuric acid, and 500g of hydrogen peroxide to the selenium-containing material, heat at 90°C, stir the acid-oxygen leaching solution for 3 hours, and filter to obtain 5.83kg of filter residue (including 0.28% selenium), and 30.98% of the acid-oxygen leaching solution L; the leaching slag is sent to pyrometallurgy to recover lead, bismuth and copper;

[0035] (3) Add 785g of anhydrous sodium sulfite to the acid oxygen leaching solution produced in the previous step, heat at 90°C, stir for 1.5 hours and filter to obtain 395.8g of coarse selenium powder; return the deselenized water to acid oxygen leaching;

[0036] (4) Add 2400g of water and 533.25g of sulfuric acid to the selenium-containing material, heat at 90°C, stir for 3 hours, and filter to obtain 18.0 g of filter residue (including 11.6% selenium), and 2483mL of secon...

experiment approach 3

[0039] (1) Take 500g of selenium-containing raw material, which contains 3% selenium, and grind it to 120 mesh;

[0040] (2) Add 1500g of water, 150g of sulfuric acid, and 25g of hydrogen peroxide to the selenium-containing material, heat at 90°C, stir the acid-oxygen leaching solution for 3 hours, and filter to obtain 325g of leaching residue (including 0.25% selenium), and 1538mL of acid-oxygen leaching solution ; The leaching slag is sent to pyrometallurgy to recover lead, bismuth and copper;

[0041] (3) Add 30g of anhydrous sodium sulfite to the acid oxygen leaching solution produced in the previous step, heat at 90°C, stir for 1.5 hours and filter to obtain 14.8g of coarse selenium powder; return the deselenized water to acid oxygen leaching;

[0042] (4) Add 100g of water and 20g of sulfuric acid to the selenium-containing material, heat at 90°C, stir for 3 hours, and filter to obtain 0.89 g of filter residue (including 12.5% selenium), and 110mL of secondary leaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com