Low concentration coal chemical industrial wastewater processing system

A coal chemical wastewater and treatment system technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Energy consumption, anoxic stirring, high energy consumption, etc., to achieve the effect of improving processing capacity, reducing energy consumption, and high-efficiency load impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

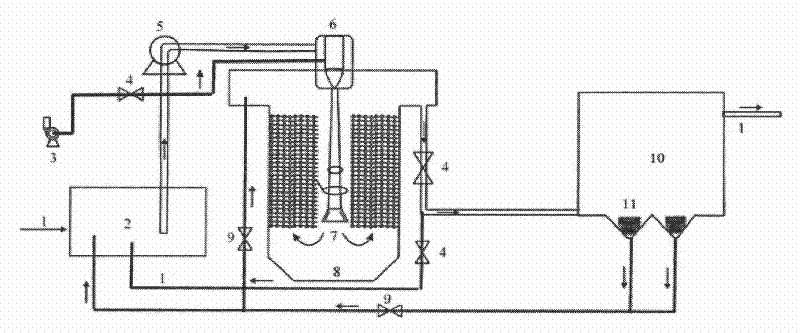

[0039] Such as figure 1 As shown, the low-concentration coal chemical wastewater is first fully homogenized in the regulating tank, and then transported from pipeline 1 to the anoxic tank 2. The denitrifying bacteria in the anoxic tank are used to fully denitrify, reduce the concentration of total nitrogen, and basically maintain anoxic The dissolved oxygen in the system is in the range of 0.0-0.1mg / L. The mixed liquid in the anoxic tank 2 is transported through the jet water pump 5 and distributed to the MFB reactor 8 by means of the jet 6. At the same time, the jet aeration system passes through the blower 3 and The valve 4 controls the amount of aeration, and blows and pressurizes the aeration of the ejector to improve the treatment efficiency of the ejector. The MFB reactor 8 is attached with high-efficiency composite packing. The dense packing can increase the total amount of microorganisms in the wastewater, and form three layers of anaerobic, anoxic and aerobic biofilms...

Embodiment 2

[0041] Coal chemical wastewater from a chemical company in Anhui (using aerospace gasification technology), designed to treat water volume: 1,000m 3 / d.

[0042] Table 2 Water quality of low-concentration coal chemical industry wastewater (space furnace)

[0043]

[0044] Process according to the process of Example 1, wherein technical indicators: anoxic section residence time HRT=16hr; MFB reactor residence time HRT=24hr; Alkali dosage: 150kg / d; Methanol dosage: 30kg / d; Surface load: 0.5m 3 / (m 2 d), power consumption per ton of water: 1.3KW h / m 3 .

[0045] Compared with the traditional SBR, the dosage of methanol is 20kg / d less, the floor area is saved by 20%, and the operating cost is saved by more than 40%.

Embodiment 3

[0047] A urea and methanol low-concentration coal chemical industry treatment wastewater in Shaanxi, the main water quality is shown in Table 3

[0048] Table 3 Influent and effluent indicators of wastewater treatment station

[0049]

[0050]

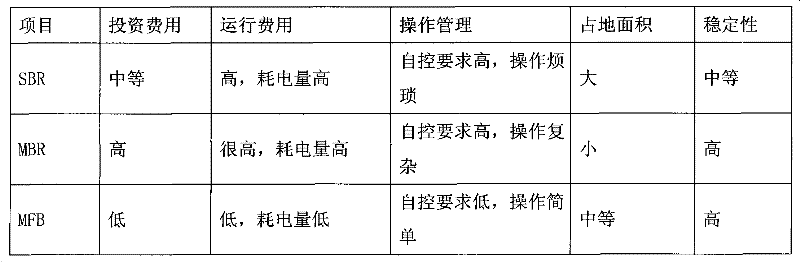

[0051] Process according to the process of Example 1, after the system treatment of the present invention: the effluent COD is less than 60mg / L, the ammonia nitrogen is less than 8mg / L, the amount of treated water is 200m3 / h, and the power consumption per ton of water is 2.84 kWh / ton of water, which is far lower than The SBR system is 5 kWh / ton of water and the MBR system is 4.84 kWh / ton of water.

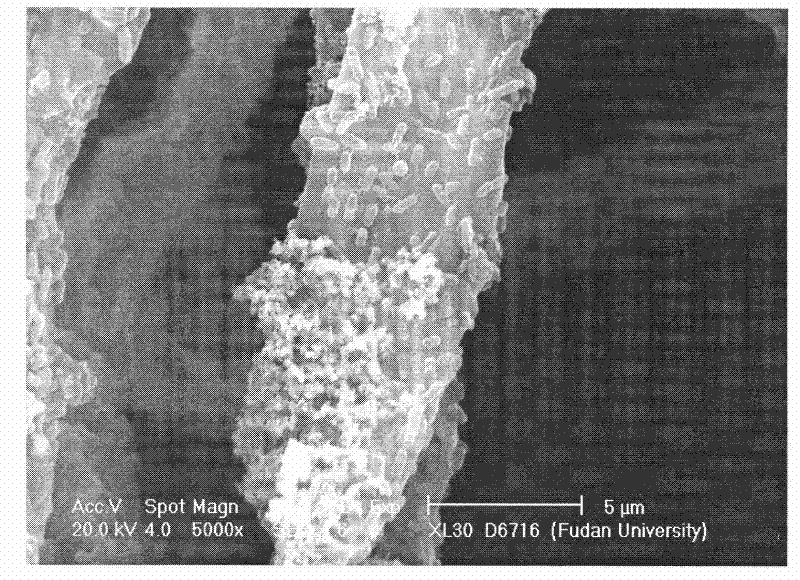

[0052] The efficient filler used in embodiment 2 and embodiment 3, through molecular specific surface area test, novel filler specific surface area is 584m 2 / m 3 , much higher than the conventional fillers commonly used at present.

[0053] Table 1

[0054] project

[0055] Such as figure 2 As shown, the microbes ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com