High performance multilayer ceramic capacitor medium and preparation method thereof

A technology of capacitor dielectric and multilayer ceramics, which is applied in the direction of fixed capacitor dielectric, laminated capacitor, fixed capacitor components, etc., to achieve high dielectric constant, low sintering temperature, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

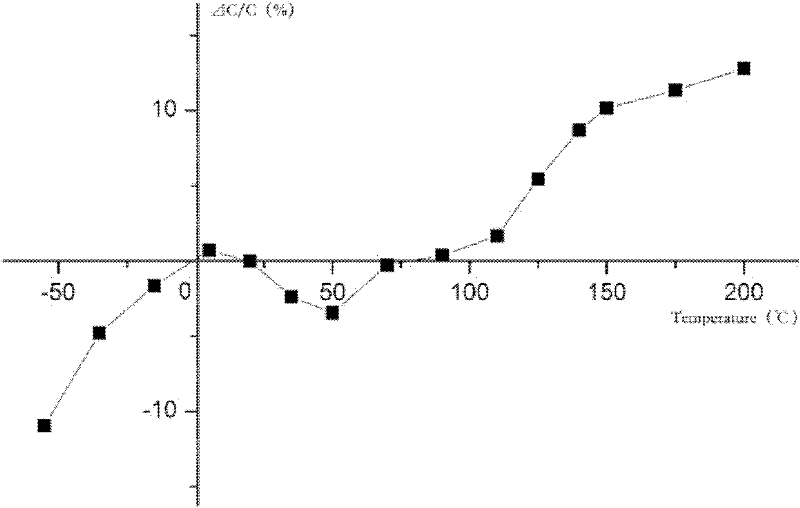

Embodiment 1

[0033] According to the ingredient formula: {[(1-x)BaTiO 3 +xNBT]+ywt%Nb 2 o 5}+z wt%MgO+a wt%Glass+b wt%RE 2 o 3 +c wt%MnCO 3 ; Wherein the composition of Glass is: 8% SnO 2 +2%PbO+15%TiO2 +40% Bi 2 o 3 +35%B 2 o 3 ; First synthesize bismuth sodium titanate phase, according to Bi 2 o 3 :Na 2 CO 3 :TiO 2 = 1: 2: 6 molar ratio for batching ball milling, pre-synthesis of bismuth sodium titanate phase at 920 ° C after drying; then according to [(1-x) BaTiO 3 -+x NBT]+y wt%Nb 2 o 5 Take x=0.15, y=2.4, weigh, ball mill, and pre-burn at 1300°C for 2 hours; take z=1.2, a=4, b=0, c=0 in the total ingredient formula; put the above materials through Mix evenly by ball milling, then dry, and after sieving, add a binder, the binder is paraffin wax, the amount added is 8wt% of the total mass of the ingredients, and granulated into uniform granules; pressed under a pressure of 180Mpa to make a diameter of 16mm , a wafer with a thickness of 1mm, and then sintered, that is, t...

Embodiment 2

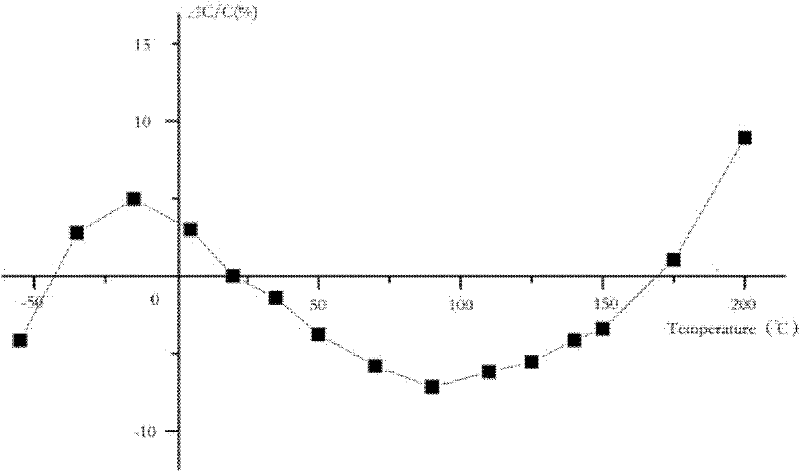

[0036] According to the formula {[(1-x)BaTiO 3 +xNBT]+ywt%Nb 2 o 5}+z wt%MgO+a wt%Glass+b mol%RE 2 o 3 +c MnCO 3 ; Wherein the composition of Glass is: 12% SnO 2 +18%PbO+9%TiO 2 +34% Bi 2 o 3 +27%B 2 o 3 ; First synthesize bismuth sodium titanate phase, according to Bi 2 o 3 :Na 2 CO 3 :TiO 2 = 1: 1: 2 molar ratio for batching ball milling, pre-synthesis of bismuth sodium titanate phase at 700 ° C after drying; then according to [(1-x) BaTiO 3 +xNBT]+ywt%Nb 2 o 5 Take x=0.15, y=2.6, weigh, ball mill, and pre-burn at 1190°C for 3 hours; take RE=La, z=1.7, a=1, b=0.001, c=0 in the total ingredient formula; Mix the above materials uniformly by ball milling, then dry, and after sieving, add a binder, the binder is paraffin wax, the addition amount is 8wt% of the total mass of the ingredients, granulated into uniform particles, and pressed under a pressure of 180Mpa. Form a disc with a diameter of 16mm and a thickness of 1mm, and then sinter, that is, increase the...

Embodiment 3

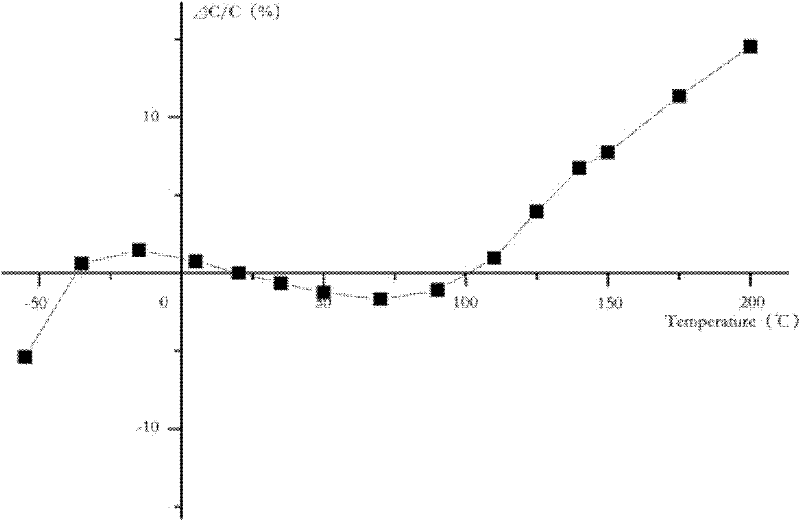

[0039] According to the formula {[(1-x)BaTiO 3 +xNBT]+ywt%Nb 2 o 5}+z wt%MgO+a wt%Glass+b mol%RE 2 o 3 +c MnCO 3 ; Wherein the composition of Glass is: 15% SnO 2 +3%PbO+25%TiO 2 +42% Bi 2 o 3 +15%B 2 o 3 ; First synthesize bismuth sodium titanate phase, according to Bi 2 o 3 :Na 2 CO 3 :TiO 2 = 1: 2: 5 molar ratio for batching ball milling, pre-synthesis of bismuth sodium titanate phase at 870 ° C after drying; then according to [(1-x) BaTiO 3 +xNBT]+ywt%Nb 2 o 5 Take x=0.20, y=2.2, weigh, ball mill, and pre-burn at 1500°C for 5 hours; take RE=Nd, z=1.0, a=2, b=0.008, c=0.2 in the total ingredient formula; Mix the above materials uniformly by ball milling, then dry, and after sieving, add a binder, the binder is paraffin wax, the addition amount is 8wt% of the total mass of the ingredients, granulated into uniform particles, and pressed under a pressure of 180Mpa. Form a disc with a diameter of 16mm and a thickness of 1mm, and then sinter, that is, increase t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com