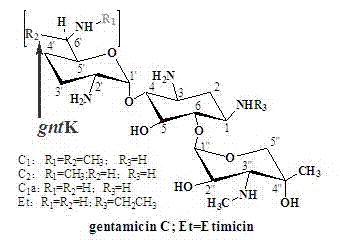

Engineering bacteria for producing gentamicin C1a and application thereof

A gentamicin, engineering bacteria technology, applied in the direction of enzymes, bacteria, microorganism-based methods, etc., can solve the problems of serious pollution, slow progress in the application of Micromonospora, and long chromatographic separation cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention comprises following main steps:

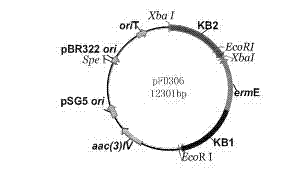

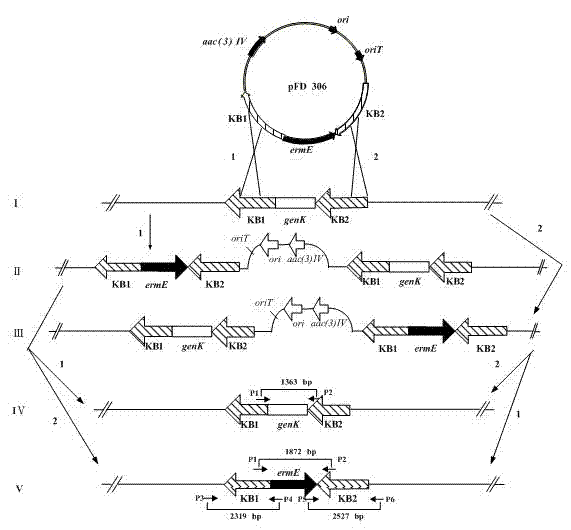

[0030] 1. Construct wxya gene replacement plasmid

[0031] According to the gentamicin biosynthetic gene cluster (refer to GenBank Accession Number AY524043), respectively in wxya Two pairs of primers LB1 and LB2 and LB3 and LB4 were designed upstream and downstream of the gene (SEQ.NO.1) to start the strain S-1212 (Zhou Xiaolan, Huang Jianzhong, , Shi Bihong, Shi Qiaoqin. Affecting Micromonospora magenta ( Micromonospora purpurea) S-1212 spore germination of several main factors. Fujian Normal University Journal (Natural Science Edition), Vol.18 No.1, p72-75) chromosomal DNA (CTAB method) as a template, PCR, amplified The DNA sequence at both ends of gntK was added as a homologous exchange arm; the upstream exchange arm was called KB1 (LB1 / LB2) with a length of 2076 bp; the downstream exchange arm was called KB2 (LB3 / LB4) with a length of 2044 bp. Plasmid pAGe was used as template (Zhu Biyin, Hong Wenr...

Embodiment 2

[0040] Example 2: Preparation of Metabolite C1a of Micromonospora magenta GK1101

[0041] provided by the invention wxya The inactivated engineering bacteria Micromonospora crimson GK1101 can be directly used to manufacture gentamicin C1a. The preparation of gentamicin C1a is as follows (Hong Wenrong. Optimization of gentamicin fermentation process. Chinese Journal of Pharmaceutical Industry. 1994, 25(1).p1-3,):

[0042] 1. Fermentation of Micromonospora magenta strain GK1101

[0043] Seed medium: glucose 0.1%, corn starch 1.0%, corn flour 1.5%, peptone 0.2%, soybean cake powder 1.0%, KNO3 0.05%, CaCO3 0.5%, pH7.0.

[0044] Fermentation medium: corn starch 6.0%, corn flour 1.0%, peptone 0.4%, soybean cake powder 2.0%, KNO 3 0.01%, (NH 4 ) 2 SO 4 0.1%, CaCO 3 0.5%, amylase 0.025%, pH7.5.

[0045] Shake flask fermentation: Micromonospora magenta GK1101 obtained in step 3 of Example 1 was fermented. Before fermentation, isolate the single colony with rich sporulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com