Preparation method of needle-like nano calcium carbonate

A nano-calcium carbonate and needle-shaped technology, which is applied in the field of preparation of needle-shaped nano-calcium carbonate powder, can solve the problems that the needle-shaped calcium carbonate orientation and reinforcement effect cannot be achieved, the proportion of needle-shaped products decreases, and the agglomeration is serious. Easy process adjustment and control, good dispersibility, good dispersibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Adding 5 liters of calcium hydroxide mass concentration in 7 liters of stirred reactor is 10% initial temperature of refined milk of lime at 26°C, add 20.3g ethylenediaminetetraacetic acid and 16.9g aluminum chloride, after stirring, pass Inject carbon dioxide volume concentration of 98% CO 2 -N 2 The carbonization reaction of the mixed gas starts, and the gas flow rate is 60L / h;

[0027] When the carbonization reaches a pH of 6.8, continue aeration for 15 minutes, stop aeration carbonization, and the final temperature of the reaction system reaches 49°C.

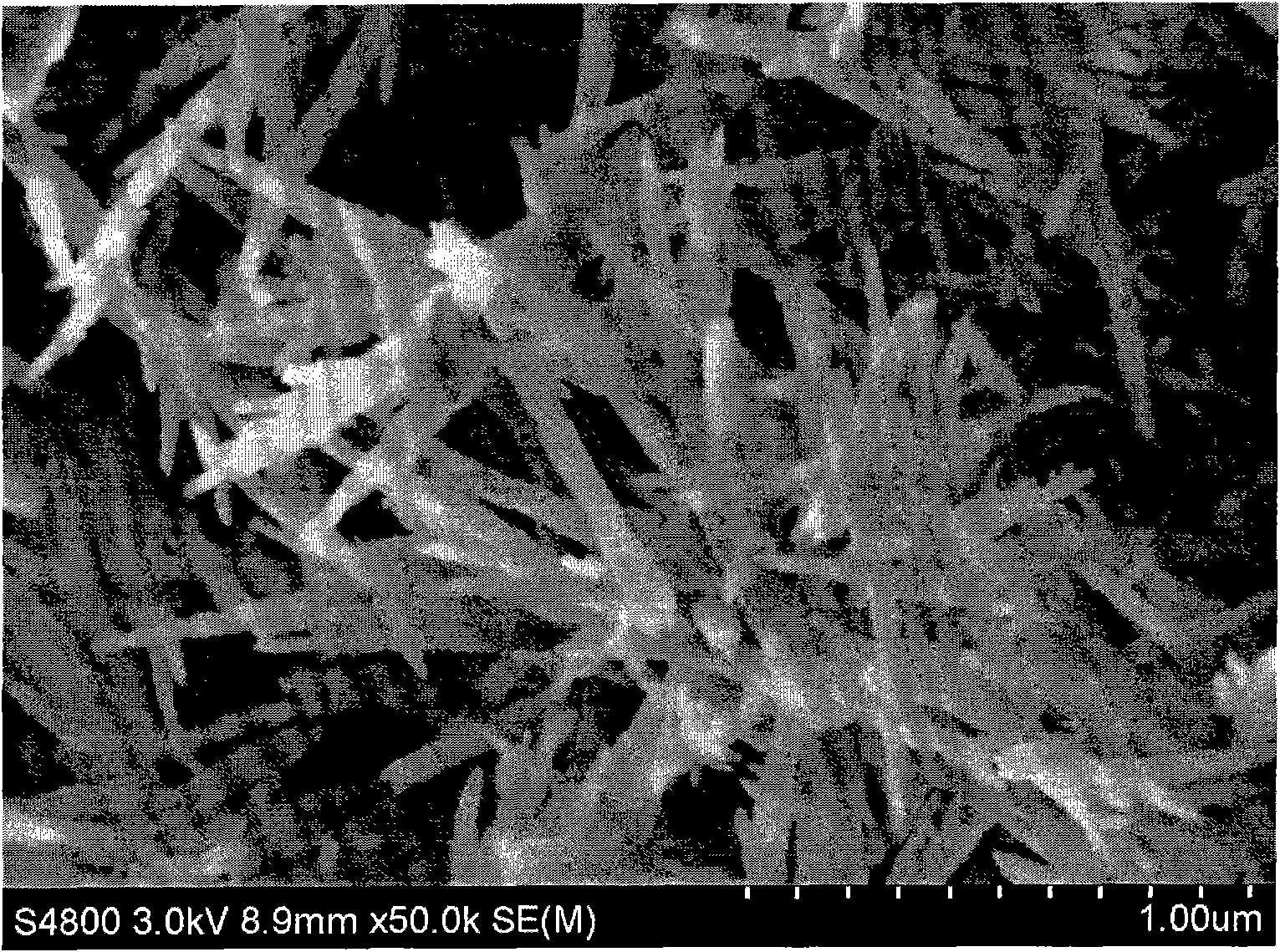

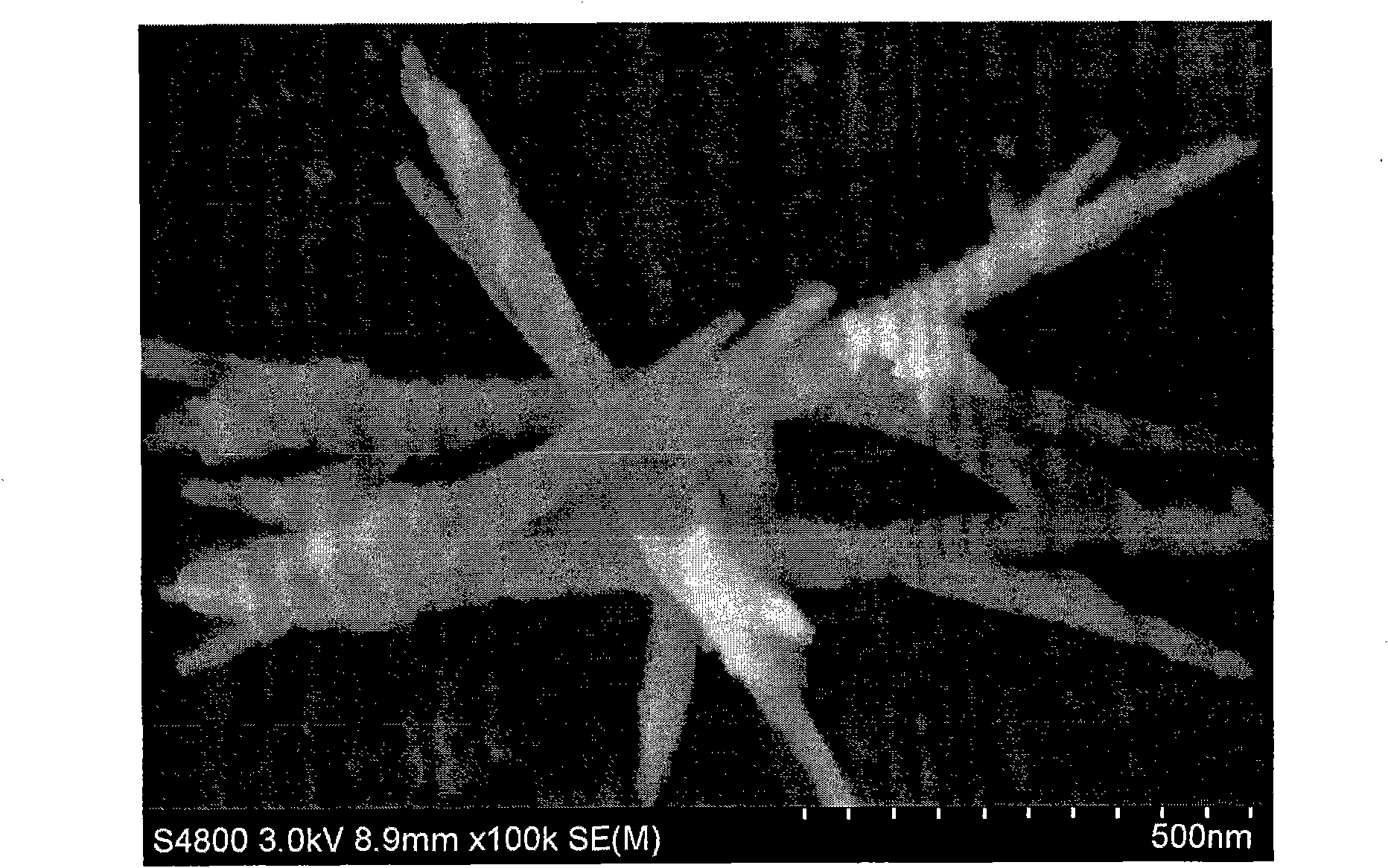

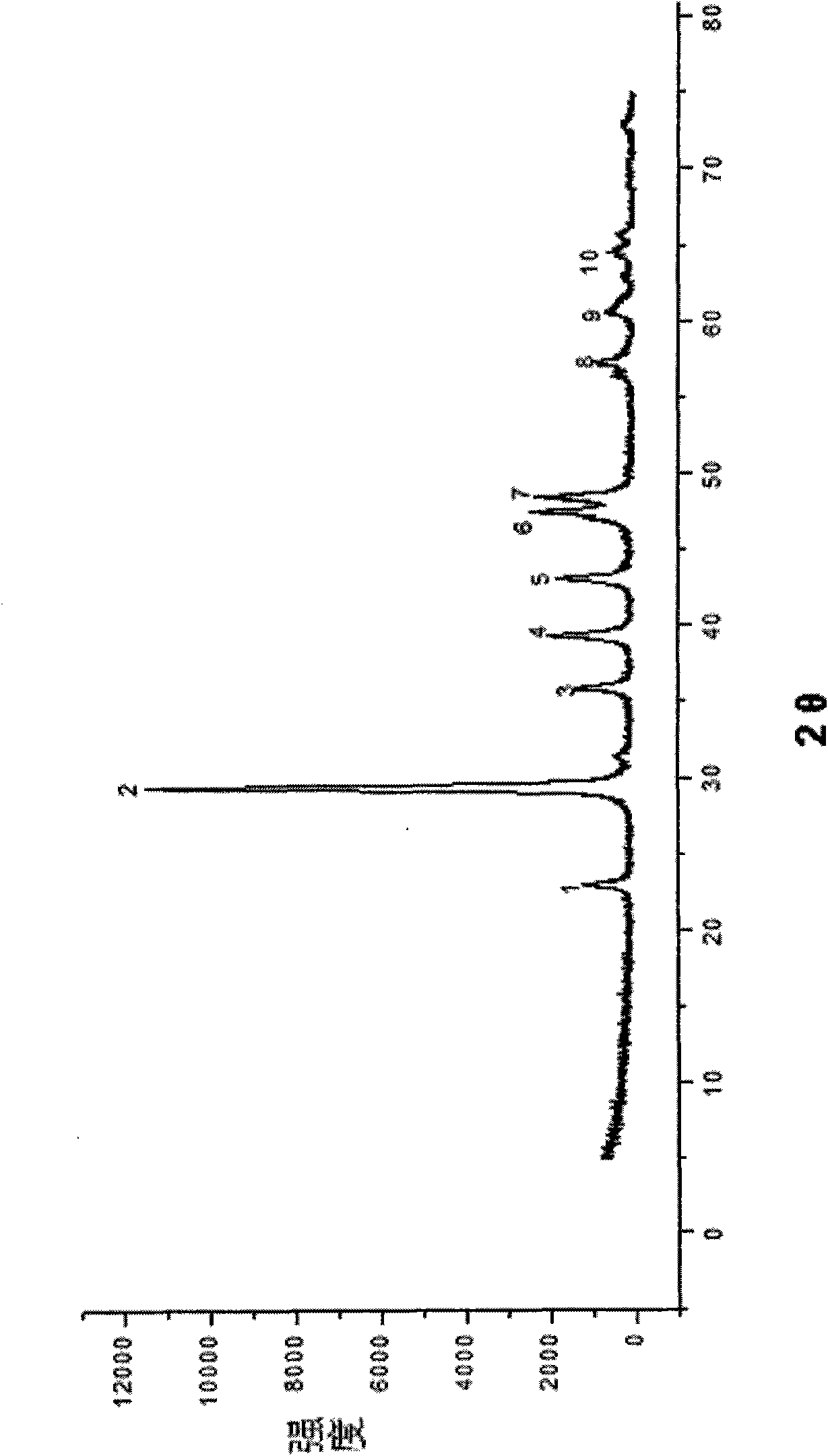

[0028] The resulting product was observed with a scanning electron microscope, and its appearance was needle-shaped, with an aspect ratio of 35, a particle size of 22nm, and a narrow particle size distribution range; its specific surface area was 76.4m 2 / g, XRD analysis is calcite crystal form.

Embodiment 2

[0030] Add 5 liters of refined milk of lime with a mass concentration of calcium hydroxide of 14% and an initial temperature of 37°C in a 7-liter stirred reactor, add 13.5 g of citric acid and 7.4 g of zinc sulfate at the same time, and after stirring, pass in a volume of carbon dioxide Concentration of 33% CO 2 -N 2 Mixed gas for carbonization reaction, the gas flow rate is 200L / h;

[0031] When the carbonization reaches a pH of 7.0, continue aeration for 20 minutes, stop the aeration carbonization, and the final temperature of the reaction system reaches 59°C.

[0032] The resulting product was filtered and dried, and observed with a scanning electron microscope. Its appearance was needle-shaped, the aspect ratio was 10, the particle size was 45nm, and the particle size distribution range was narrow; its specific surface area was measured as 49.0m 2 / g, XRD analysis is calcite crystal form.

Embodiment 3

[0034] In a bubbling carbonization tower of 20 liters (inner diameter 140mm, height-to-diameter ratio 8: 1), add 15 liters of calcium hydroxide mass concentration and be the refined milk of lime of 26 ℃ with the initial temperature of 8%, add 24.3g ethylenediamine simultaneously Tetraacetic acid and 21.1g aluminum sulfate, after stirring evenly, pass into the CO that the volume concentration of carbon dioxide is 50% 2 -N 2 The carbonization reaction of the mixed gas starts, and the gas flow rate is 610L / h;

[0035] When the carbonization reaches a pH of 6.8, continue aeration for 30 minutes, stop the aeration carbonization, and the final temperature of the reaction system reaches 47°C.

[0036] The resulting product was filtered and dried, and observed with a scanning electron microscope. Its appearance was needle-shaped, the particle diameter was 34nm, the aspect ratio was 13, and the particle size distribution range was narrow; its specific surface area was 52.3m 2 / g, XRD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com