Alkylation method of benzene and ethanol

An ethanol alkyl, ethanol technology, applied in chemical instruments and methods, organic chemistry, bulk chemical production, etc., to achieve good technical effects, inhibit carbon deposition, and improve reaction stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Mix and stir 162 grams of silica sol (40% by weight), 14 grams of aluminum sec-butoxide, and 322 grams of dimethyl diethylammonium hydroxide (20% by weight), and age at 100° C. for 18 hours. Cool, for the precursor solution. The molar ratio of each component in the mixture is SiO 2 / Al 2 o 3 =40,H 2 O / SiO 2 =18, R / SiO 2 = 0.5.

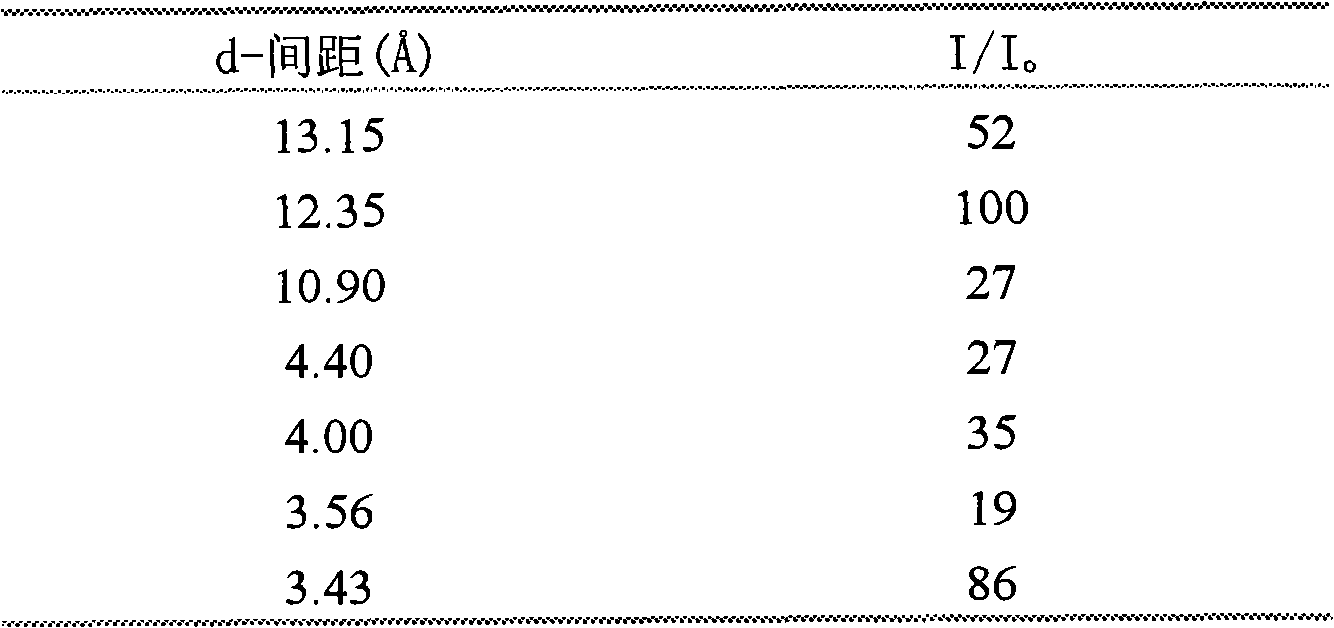

[0019] With 2.2 grams of sodium hydroxide, 16 grams of silica sol (40% by weight), 1.4 grams of aluminum sec-butoxide, 10 grams of precursor solution, 26 grams of distilled water, mix and stir evenly, the molar ratio of each component is SiO 2 / Al 2 o 3 =36,H 2 O / SiO 2 =20,OH - / SiO 2 = 0.43. Raise the temperature to 160°C for crystallization of the above mixture. After 48 hours of crystallization, cool the crystallization tank to room temperature, take out the crystallization liquid, centrifuge, wash and filter, and put the product in an oven for 8 hours at 100°C. . The X-ray powder diffraction data are shown in Table 1.

[0020...

Embodiment 2

[0025]Mix and stir 162 grams of silica sol (40% by weight), 14 grams of aluminum sec-butoxide, and 322 grams of dimethyl diethylammonium hydroxide (20% by weight), and age at 100° C. for 18 hours. Cool, for the precursor solution. The molar ratio of each component in the mixture is SiO 2 / Al 2 o 3 =40,H 2 O / SiO 2 =18, R / SiO 2 = 0.5.

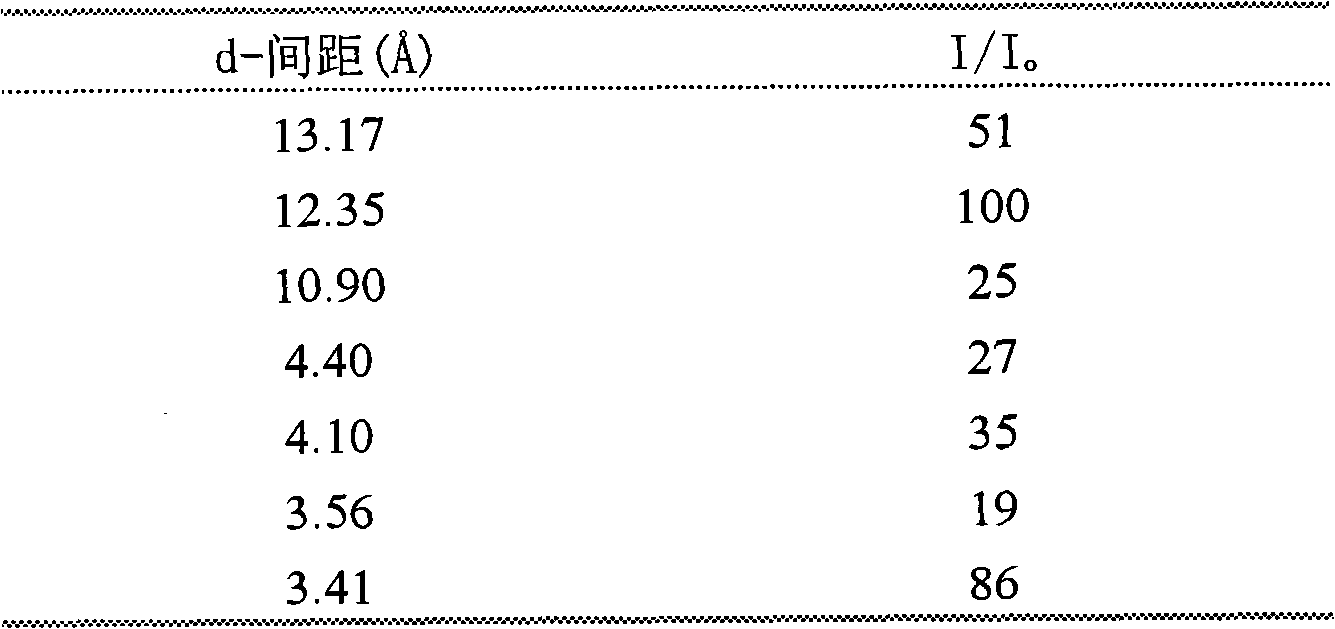

[0026] 2.2 grams of sodium hydroxide, 16 grams of silica sol (40% by weight), 0.7 grams of aluminum sec-butoxide, 9 grams of precursor solution, and 26 grams of distilled water were mixed and stirred evenly, and the molar ratio of each component was SiO 2 / Al 2 o 3 =65,H 2 O / SiO 2 =19,OH - / SiO 2 = 0.43. Raise the temperature to 160°C for crystallization of the above mixture. After 48 hours of crystallization, cool the crystallization tank to room temperature, take out the crystallization liquid, centrifuge, wash and filter, and put the product in an oven for 8 hours at 100°C. . The X-ray powder diffraction data are shown in Table ...

Embodiment 3

[0032] Mix 170 grams of tetraethyl orthosilicate, 5 grams of aluminum sec-butoxide, 151 grams of ethyltrimethylammonium hydroxide (20% by weight), and 80 grams of distilled water to form a mixture I, stir well, and age at 100° C. After 16 hours of cooling, it is the precursor solution. The molar ratio of each component in the mixture is SiO 2 / Al 2 o 3 =80,H 2 O / SiO 2 =21, R / SiO 2 = 0.25.

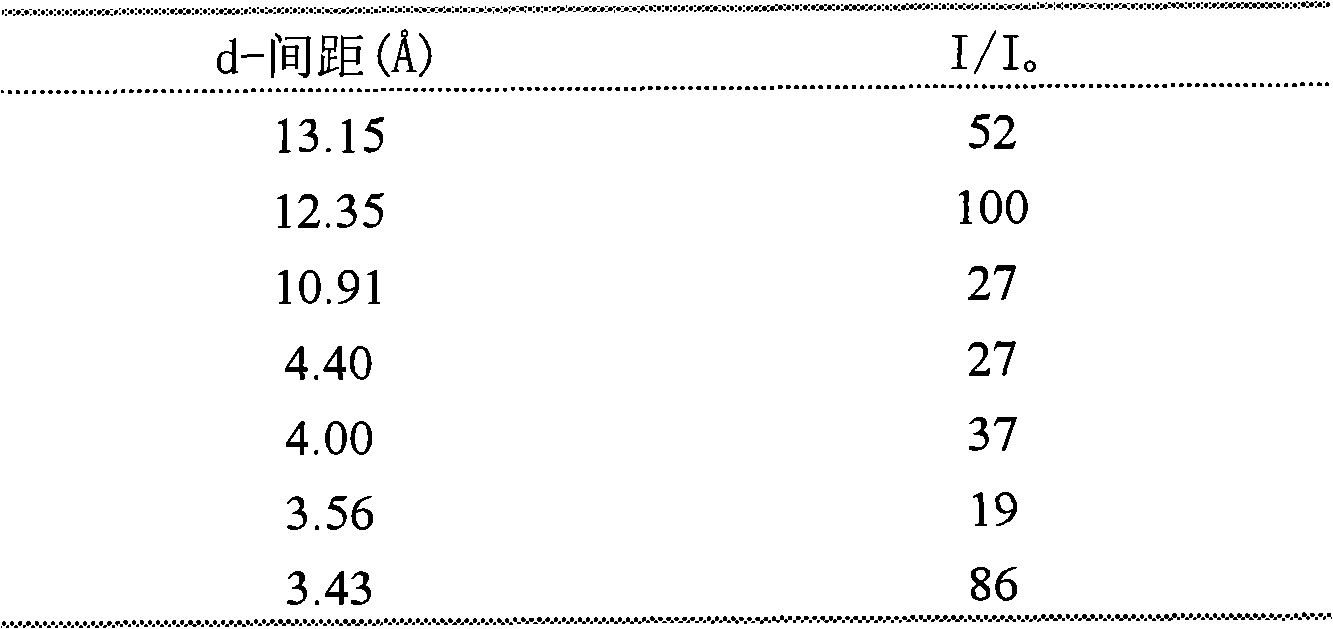

[0033] Mix and stir 1.3 grams of sodium hydroxide, 20 grams of tetraethyl orthosilicate, 1.0 grams of aluminum isopropoxide, 12 grams of precursor solution, and 50 grams of distilled water, and the molar ratio of each component is SiO 2 / Al 2 o 3 =44,H 2 O / SiO 2 =26,OH - / SiO 2 =0.27. Raise the temperature to 160°C for crystallization of the above mixture. After 56 hours of crystallization, cool the crystallization tank to room temperature, take out the crystallization liquid, centrifuge, wash and filter, and put the product in an oven to dry at 100°C for 8 hours. . The X-ray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com