Preparation method of polyester chip for thick membrane with thickness of more than 150mum

A polyester chip and polyester technology is used in the synthesis and processing of polyester chips and the preparation of polyester raw material chips to achieve the effect of excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

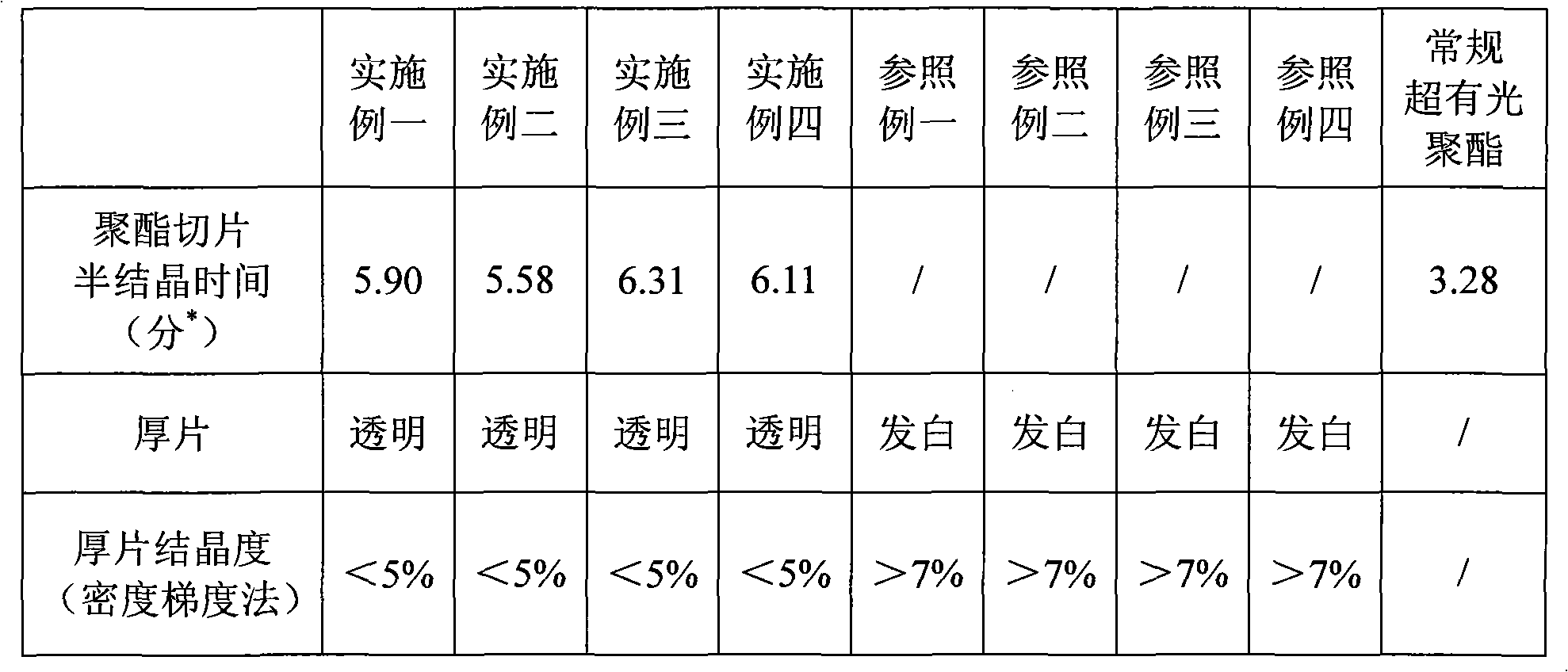

Examples

preparation example Construction

[0018] In the above preparation method, the dibasic acid is one or more of terephthalic acid, phthalic acid or isophthalic acid, and the addition amount of phthalic acid or isophthalic acid is relative to the obtained 0.5% to 8% of the weight of polyester chips; the diol is one or more of ethylene glycol diols, and the molar ratio of dibasic acid to diol is 1:1.0 to 1:2.0 , preferably 1:1.1 to 1:1.6.

[0019] The polyhydric organic matter is one or more of hexanehexanol, 1,2,3,4,5-pentanepentol, and trimethylolpropane, and its addition is relative to the quality of the obtained polyester chips. 50~5000ppm. In specific operations, it can be directly added to the polyester synthesis system, or it can be prepared into a solution with a mass concentration of no more than 15% with the diol used in the reaction within the temperature range of 90-110 ° C, and then added to the polyester in the synthetic system.

[0020] The anti-adhesive agent is one of talc, calcium carbonate, ba...

Embodiment 1

[0029] In the 20L polymerization device, add 4.8kg PTA (purified terephthalic acid), 3kg EG (ethylene glycol), 1.511g ethylene glycol antimony, 0.2kg IPA (isophthalic acid), 57.6g barium sulfate, at 230 Carry out esterification reaction at ~265℃, 0.2~0.3MPa, when the water output reaches 1200ml, release the pressure to normal pressure, add 0.3g of 1,2,3,4,5-pentanepentaol, 1.025g of triphenyl phosphate , stirred at normal pressure for 10 minutes, raised the temperature and lowered the pressure to 280° C. and below 100 Pa, and reacted for 1.5 to 3 hours. After the reaction is completed, it is extruded by a melt pump, pelletized and dried to obtain polyester chips.

[0030]Pre-crystallize the obtained polyester chip, dry, extrude, longitudinally and laterally biaxially stretch, heat-set, relax, and cool to make a 150 μm single-layer film. Among them, the casting temperature is 25-45°C, the extrusion temperature is 275-285°C, the longitudinal drawing temperature is 90-120°C, the...

Embodiment 2

[0032] In a 20L polymerization device, add 4.9kg PTA, 3kg EG, 0.98g potassium fluotitanate, 0.1kgIPA, 57.6g kaolin, carry out esterification reaction at 230~265℃, 0.2~0.3MPa, and wait until the water output reaches 1200ml , release the pressure to normal pressure, add 3g of hexanediol and 0.44g of trimethyl phosphate, stir at normal pressure for 10 minutes, raise the temperature and lower the pressure to 280°C and below 100Pa, and react for 1.5 to 3 hours. After the reaction is completed, it is extruded by a melt pump, pelletized and dried to obtain polyester chips.

[0033] Pre-crystallize the obtained polyester chip, dry, extrude, longitudinally and laterally biaxially stretch, heat-set, relax, and cool to make a 175 μm single-layer film. Among them, the casting temperature is 25-45°C, the extrusion temperature is 275-285°C, the longitudinal drawing temperature is 90-120°C, the transverse drawing temperature is 90-120°C, the longitudinal drawing ratio is 3.1:1, and the trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Longitudinal temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com