Decoloration method for fermentation wastewater biochemical treatment tail water

A technology for biochemical treatment and fermentation wastewater, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Good decolorization effect, low operating cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

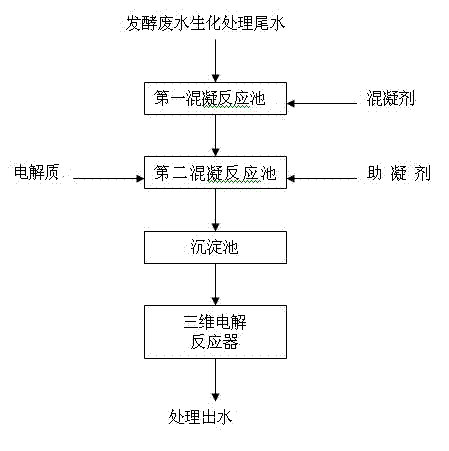

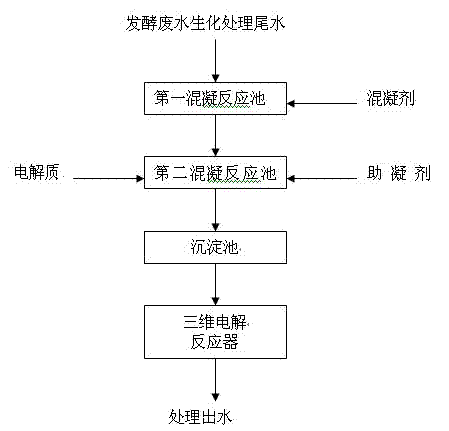

Image

Examples

Embodiment 1

[0023] The inventive method according to figure 1 The process of the treatment method is applied to the decolorization of the tail water of the vitamin C production wastewater through the secondary biochemical treatment, and the chromaticity of the influent is 250 times. Material Factory) dosage of 0.5g / L, PAM (non-ionic polyacrylamide, Shandong Liaocheng Changlong Chemical Raw Materials Co., Ltd.) dosage of 1mg / L, the chromaticity of the effluent after coagulation treatment is 200 times, the chroma removal rate is 20%. The waste water enters into the three-dimensional electrolysis reactor, and the electrolysis cell of the three-dimensional electrolysis reactor is a cuboid formed by bonding plexiglass plates, and its length, width and height are 20cm, 10cm and 16cm respectively. The cathode is a stainless steel plate, the anode is a graphite plate, and the size of the electrode plates is 10cm×16cm, a total of 3 pairs. The cathode and anode plates are connected to a DC stabili...

Embodiment 2

[0026] When the method of the present invention is applied to the biochemical treatment tail water decolorization of vitamin B12 production wastewater, the chromaticity of the influent is 300 times, and the dosage of coagulant modified PAC is 0.7g / L, and the dosage of PAM is 2mg / L. Under these conditions, the chroma of the effluent after coagulation treatment is 200 times, and the chroma removal rate is 33.3%. Wastewater enters the three-dimensional electrolysis reactor (same as Example 1), and the filling amount of activated carbon particles in the third pole is 60g / L, and the current density is 30A / m 2 1. Under the condition of voltage 10V, electrolytic treatment for 25 minutes, the chroma of the effluent is 20 times, and the chroma removal rate reaches 90%.

Embodiment 3

[0028] When the method of the present invention is applied to the decolorization of tail water of biochemical treatment of alcohol production wastewater, the chromaticity of the influent is 450 times, and the dosages of coagulant polyaluminum ferric sulfate and coagulant aid PAM are respectively 1.0 g / L and 10 mg / L Under certain conditions, the chroma of the coagulation treatment effluent is 360 times, and the chroma removal rate is 20%. The waste water enters the three-dimensional electrolysis reactor (same as Example 1), the filling amount of activated carbon particles in the third pole is 60g / L, the dosage of electrolyte NaCl is 0.2g / L, and the current density is 80A / m 2 1. Under the condition of a voltage of 12V, electrolytic treatment for 25 minutes, the chroma of the effluent is 50 times, and the chroma removal rate reaches 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com