Preparation method of high-purity amphotericin B

A high-purity amphotericin technology, applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of large loss, high production cost of amphotericin B, high operating costs, etc., and achieve improvement Quality, shorten process cycle, improve the effect of clarity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

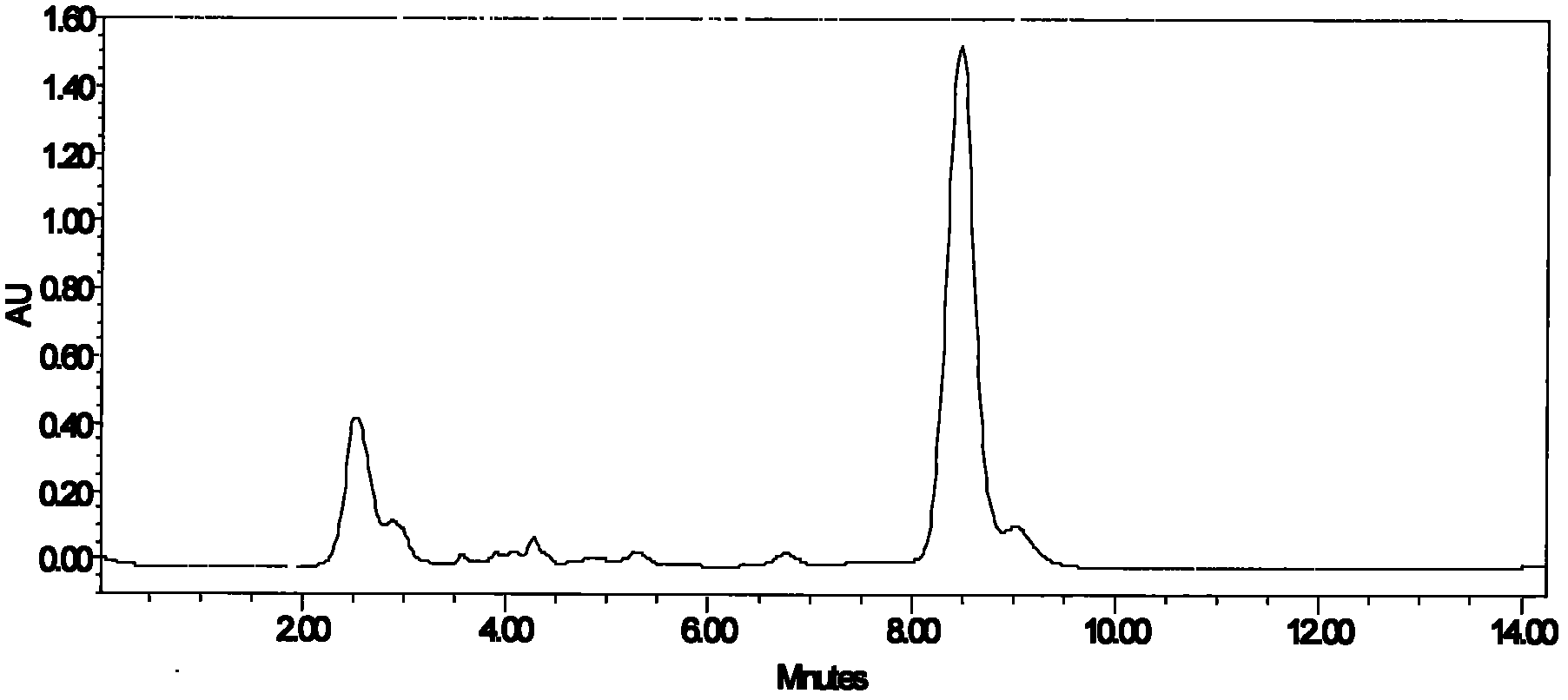

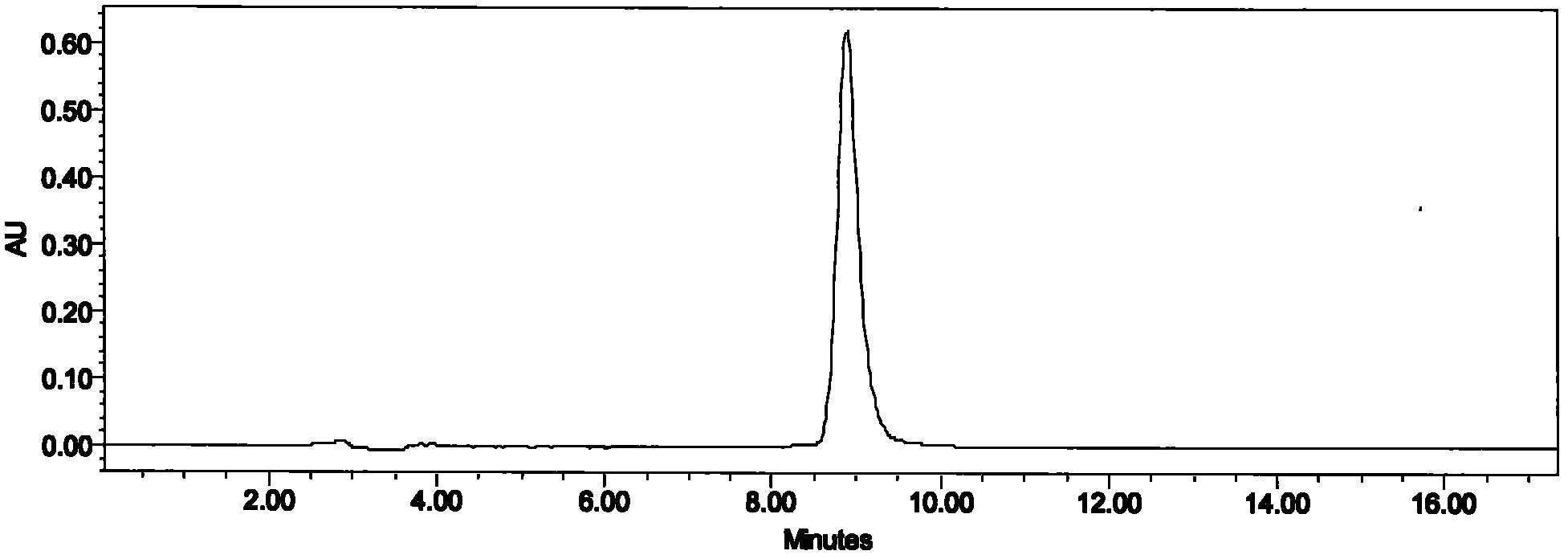

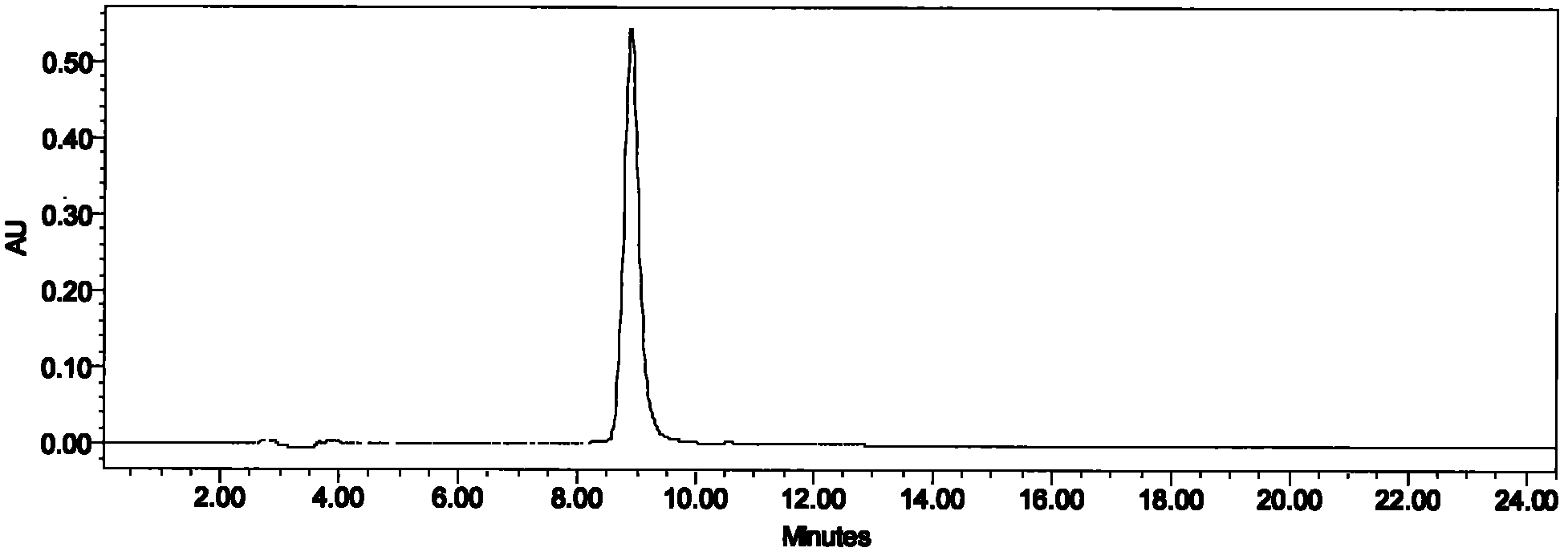

[0050] Take 50.0L of amphotericin B fermented liquid, and the fermentation unit is 7.6g / L. Add 2500g of perlite to the fermented liquid, adjust the pH value to 3.0 with oxalic acid, stir for 30 minutes and then vacuum filter to obtain 12.3kg of mycelium. Add 40L of ethanol with a mass percentage of 60% and alkaline water with NaOH to adjust the pH value to 10.5 (the amount of ethanol used is 24L, and the amount of alkaline water added is 16L) in the mycelium, and the temperature is maintained at 20°C. Stir for 1 hour and then vacuum pump filter, and collect the filtrate (see the attached figure 1 ). Pass the filtrate through a ceramic membrane module with a pore size of 200nm and a model of km1 / fr1 for decolorization, protein removal and pyrogen removal to obtain amphotericin B purification solution. The pH value of the purification solution is adjusted to 6.0-6.5 with acetic acid to precipitate the amphotericin B. Centrifuge the crystal liquid to obtain amphotericin B crys...

Embodiment 2

[0052] Take 200.0L of amphotericin B fermented liquid, and the fermentation unit is 8.2g / L. Add 10,000 g of diatomaceous earth to the fermentation broth, adjust the pH value to 2.5 with acetic acid, stir for 1 hour, and then vacuum filter to obtain 50.1 kg of mycelia. Add 200L of methanol with a mass percentage of 50% and alkaline water with NaOH to adjust the pH value to 11.5 (the amount of ethanol is 100L, and the amount of alkaline water is 100L) in the mycelia, and the temperature is maintained at 30°C. Stir for 2 hours and then vacuum pump Filter and collect the filtrate. Pass the filtrate through a ceramic membrane module with a pore size of 50 nm for decolorization, protein removal and pyrogen removal to obtain amphotericin B purification solution. The pH value of the purification solution was adjusted to 5.5-6.0 with hydrochloric acid to precipitate amphotericin B. Centrifuge the crystal liquid to obtain amphotericin B crystal powder. Vacuum drying was used to dry a...

Embodiment 3

[0054] Take 500.0L of amphotericin B fermented liquid, and the fermentation unit is 7.9g / L. Add 27000g of perlite to the fermented liquid, adjust the pH value to 3.5 with hydrochloric acid, vacuum filter after stirring for 2 hours, and obtain 253.7kg of mycelia. Add 600L of ethanol with a mass percentage of 70% and alkaline water (the amount of ethanol used is 420L, and the amount of alkaline water added is 180L) with NaOH to adjust the pH value to 12.0 in the mycelia, and the temperature is maintained at 10°C and stirred for 3 hours and then vacuum pumped Filter and collect the filtrate. Pass the filtrate through a ceramic membrane module with a pore size of 200nm for decolorization, protein removal and pyrogen removal to obtain amphotericin B purification solution. The pH value of the purification solution was adjusted to 5.5-6.0 with hydrochloric acid to precipitate amphotericin B. Centrifuge the crystal liquid to obtain amphotericin B crystal powder. Vacuum drying was u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com