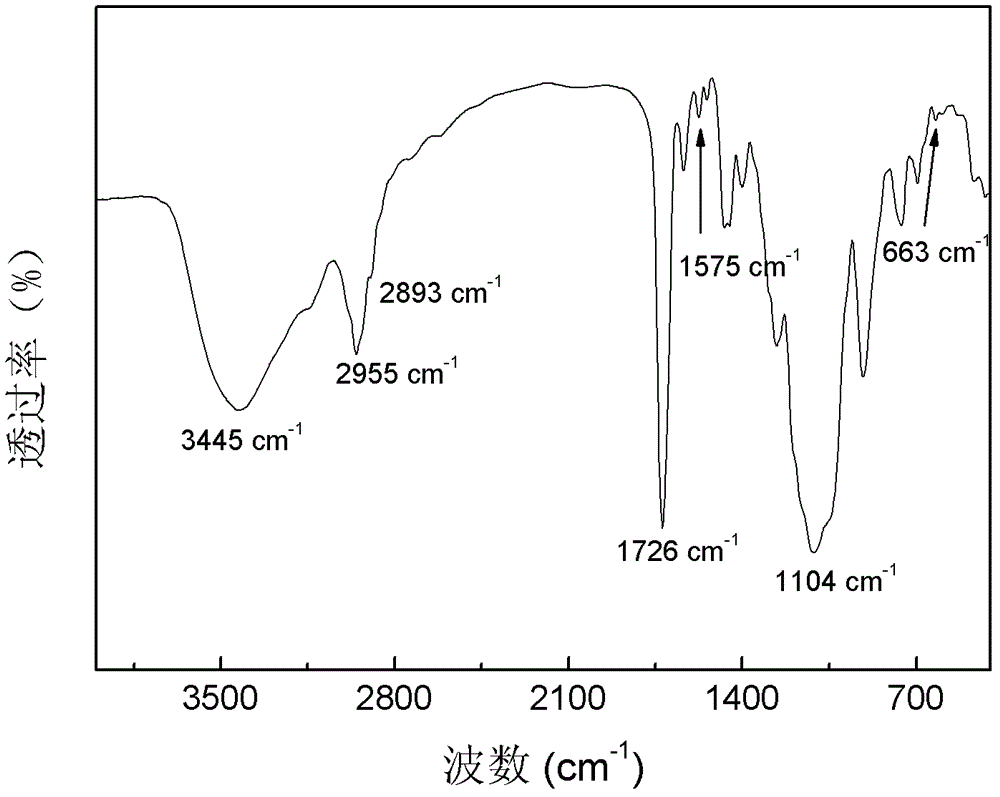

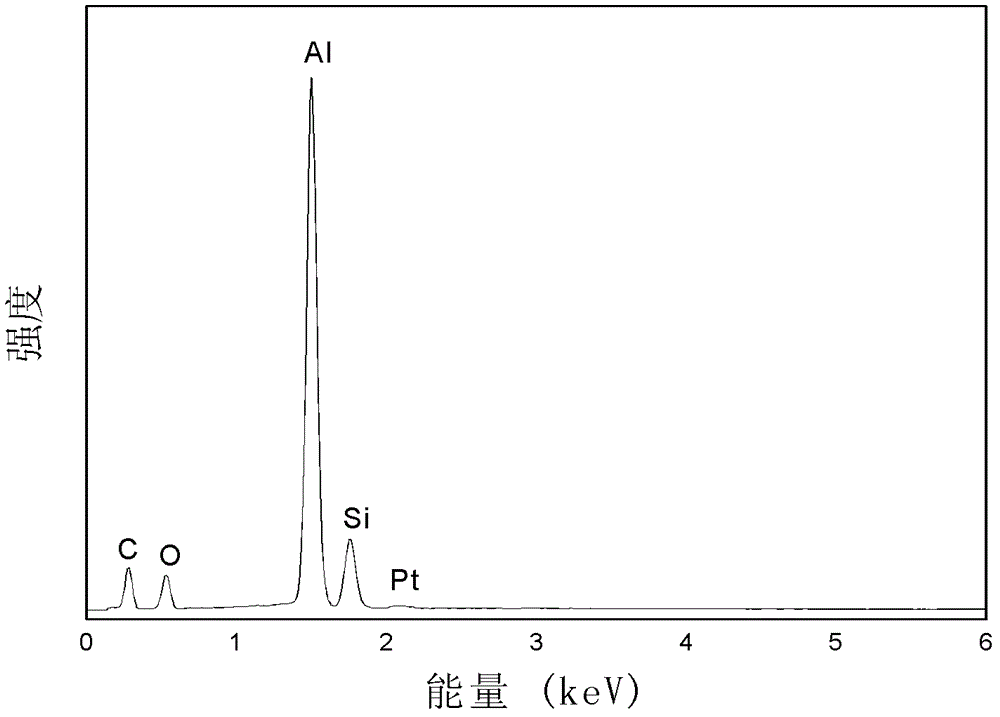

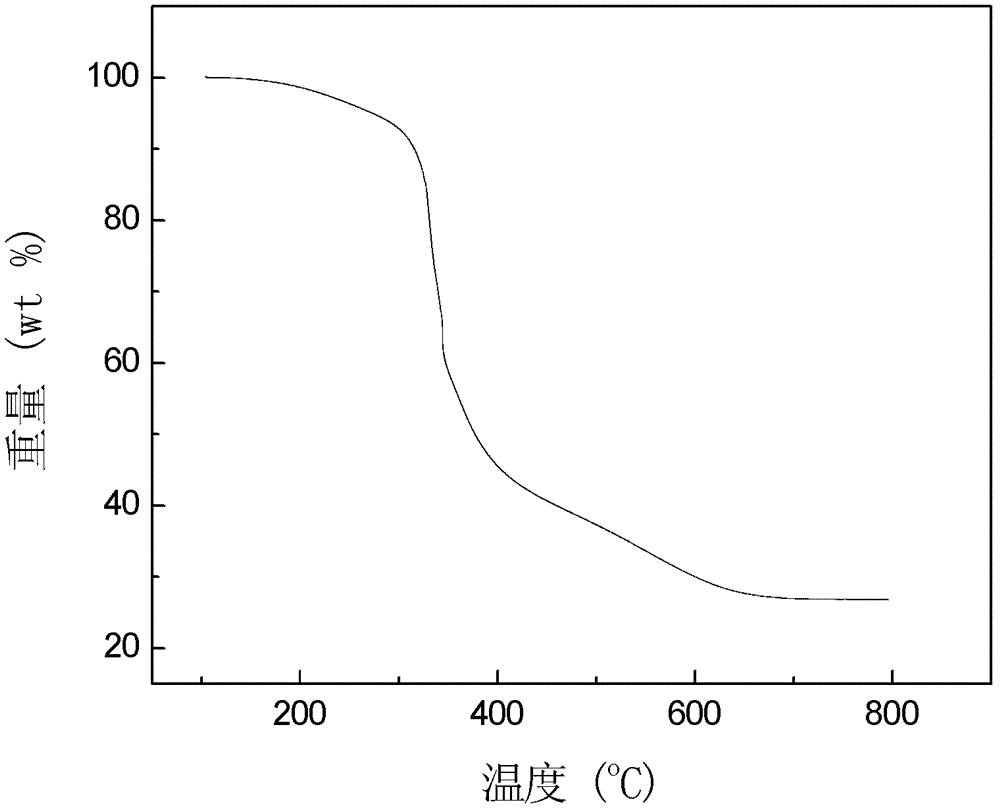

Organic-inorganic hybridized mesoporous polymer material

A polymer material and inorganic technology, applied in the field of mesoporous polymer materials, can solve the problems of limited application prospects, harsh reaction conditions, complex devices, etc., achieve the effects of wide sources, mild synthesis conditions, and avoid high temperature and high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Weigh 25 mg of cetyltrimethylammonium bromide and add it to a reaction flask filled with 190 mL of deionized water, stir vigorously, keep the reaction flask in an ice bath at 0-5°C, and pour into the above reaction flask Add 10 mL of potassium persulfate aqueous solution with a mass fraction of 0.5%, and the solution turns milky white, indicating that persulfate ions and hexadecyltrimethylammonium ions form a water-insoluble template. After keeping it for 15 minutes, add 1.5 mL of 3-(methacryloyloxy)propyltrimethoxysilane and 0.15 mL of 1-ethylene to the above reaction flask under vigorous stirring in an ice bath at 0-5°C imidazole, deoxygenated by blowing nitrogen for 10 minutes. Finally, in an ice bath at 0-5°C, add 55uL of tetramethylethylenediamine to the above reaction flask under vigorous stirring to form a reaction solution, wherein tetramethylethylenediamine initiates free radical polymerization and promotes the gradual decomposition of the template . The react...

Embodiment 2

[0038] Weigh 500mg of cetyltrimethylammonium chloride and add it to a reaction flask containing 190mL of deionized water, stir vigorously, keep the reaction flask in an ice bath at 0-5°C, and pour into the above reaction flask Add 10 mL of ammonium persulfate aqueous solution with a mass fraction of 10%, and the solution turns milky white, indicating that persulfate ions and hexadecyltrimethylammonium ions form a water-insoluble template. After keeping it for 15 minutes, add 10 mL of 3-(methacryloyloxy)propyltrimethoxysilane and 0.1 mL of 1-vinylimidazole to the above reaction flask under vigorous stirring in an ice bath at 0-5°C , deoxygenated by blowing nitrogen for 10 minutes. Finally, in an ice bath at 0-5° C., 1 mL of tetramethylethylenediamine was added to the above-mentioned reaction flask under vigorous stirring to form a reaction solution, wherein tetramethylethylenediamine initiates free radical polymerization and gradually decomposes the template. The reaction solu...

Embodiment 3

[0041] Weigh 300mg of cetyltrimethylammonium bromide and add it to a reaction flask containing 190mL of deionized water, stir vigorously, keep the reaction flask in an ice bath at 0-5°C, and pour into the above reaction flask Add 10mL of sodium persulfate aqueous solution with a mass fraction of 6%, and the solution turns milky white, indicating that persulfate ions and hexadecyltrimethylammonium ions form a water-insoluble template. After keeping it for 15 minutes, add 1 mL of 3-(methacryloyloxy)propyltrimethoxysilane and 0.4 mL of 1-vinyl imidazole, deoxygenated by blowing nitrogen for 10 minutes. Finally, in an ice bath at 0-5° C., under vigorous stirring, 400 uL of tetramethylethylenediamine was added to the above-mentioned reaction flask to form a reaction solution, wherein tetramethylethylenediamine initiates free radical polymerization and gradually decomposes the template. The reaction solution was reacted in an ice bath at 0-5°C and vigorously stirred for 12 hours un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com