Metal surface enhanced Raman scattering substrate with three-dimensional period structure and preparation method thereof

A technology that enhances Raman scattering and metal surfaces, applied in Raman scattering, material excitation analysis, etc., can solve the problems of complicated process, poor flexibility, easy to break, etc., and achieve simple and fast preparation process, high detection sensitivity, and signal Responsive even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

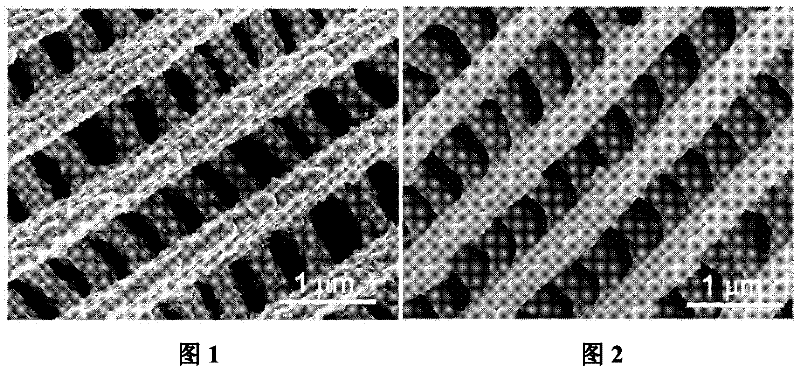

[0029] Select the natural Pteropus spp. as a template, immerse it in 8%-20% dilute nitric acid for 1-5 hours, then dry it, then immerse it in 5%-50% ethylenediamine for 6-24 hours, and then put it in 1-10 ×10 -4 M HAuCl 4 Solution 2-10 hours, alcohol cleaning, then put into 1-5% NaBH 4 2-10 minutes in solution. Rinse and dry. Then it is further put into the electroless silver plating solution with potassium sodium tartrate as the reducing agent for electroless silver plating, and the metalized butterfly wings are further taken out under the optical microscope to place a single scale on a clean silicon wafer, then drop phosphoric acid on the scale, soak 72 hours, then rinsed with deionized water, and then dried in vacuum to obtain a metal Ag surface-enhanced Raman scattering substrate with a three-dimensional periodic structure (see figure 1 ).

[0030] The metal Ag surface-enhanced Raman scattering substrate with the three-dimensional periodic structure obtained above was ...

Embodiment 2

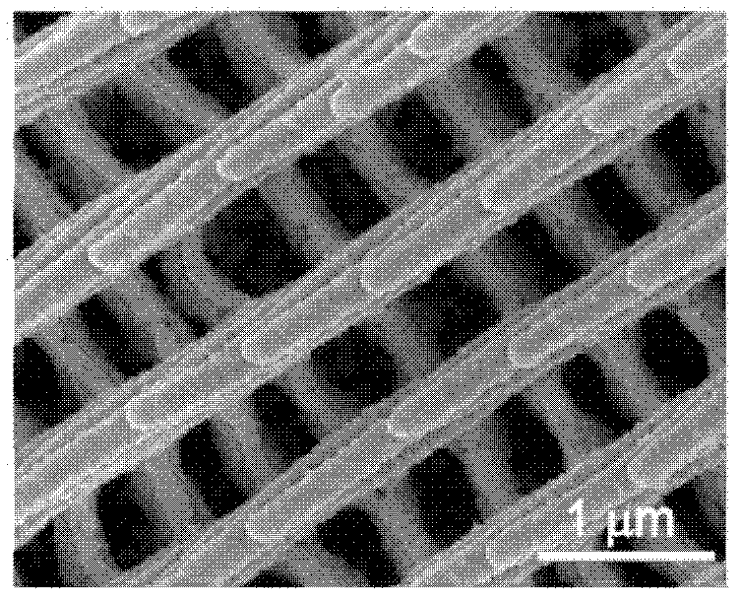

[0032]Select the natural Pteropus spp. as a template, immerse it in 8%-20% dilute nitric acid for 1-5 hours, then dry it, then immerse it in 5%-50% ethylenediamine for 6-24 hours, and then put it in 1-10 ×10 -4 M HAuCl 4 Solution 2-10 hours, alcohol cleaning, then put into 1-5% NaBH 4 2-10 minutes in solution. Rinse and dry. Then it is further put into an electroless gold plating solution with tartaric acid as a reducing agent for electroless gold plating. Further, a single scale of the metallized butterfly wing was taken out under an optical microscope and placed on a clean silicon wafer, and then phosphoric acid was dropped on the scale, soaked for 72 hours, then washed with deionized water, and then dried in a vacuum to obtain a three-dimensional periodic structure. Metallic Au surface-enhanced Raman scattering substrate (see figure 2 ).

[0033] The metal Au surface-enhanced Raman scattering substrate with a three-dimensional periodic structure obtained above was use...

Embodiment 3

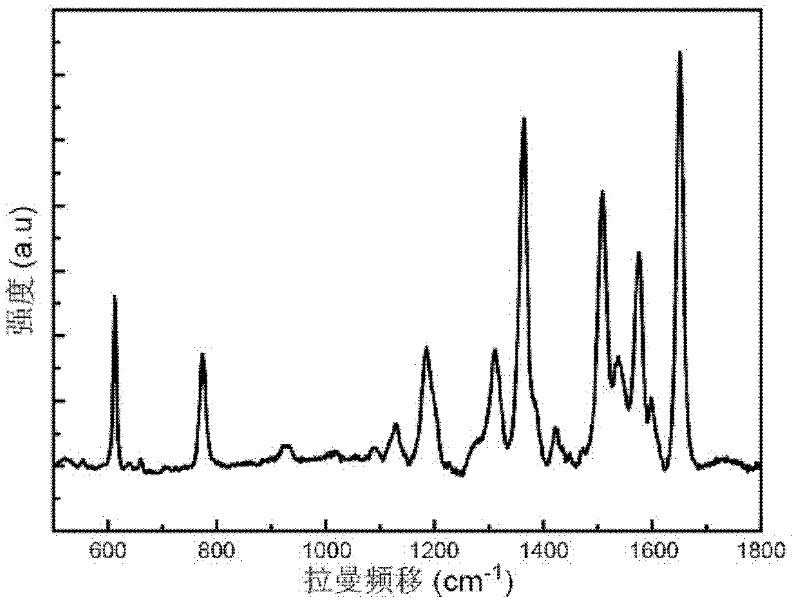

[0035] Select the natural Pteropus spp. as a template, immerse it in 8%-20% dilute nitric acid for 1-5 hours, then dry it, then immerse it in 5%-50% ethylenediamine for 6-24 hours, and then put it in 1-10 ×10 -4 M HAuCl 4 Solution 2-10 hours, alcohol cleaning, then put into 1-5% NaBH 4 2-10 minutes in solution. Rinse and dry. Then it is further put into an electroless copper plating solution with formaldehyde as a reducing agent for electroless copper plating. Further, a single scale of the metallized butterfly wing was taken out under an optical microscope and placed on a clean silicon wafer, and then phosphoric acid was dropped on the scale, soaked for 72 hours, then washed with deionized water, and then dried in a vacuum to obtain a three-dimensional periodic structure. Metallic Cu surface-enhanced Raman scattering substrate (see image 3 ).

[0036] The metal Cu surface-enhanced Raman scattering substrate with the three-dimensional periodic structure obtained above wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com