Organic/inorganic composite membrane for use in oil gas recovery and preparation method thereof

An inorganic composite membrane, organic technology, applied in the direction of separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of no organic/inorganic composite membrane, etc., achieve easy control of process conditions, improve stability, and improve high temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) For porous TiO 2 The ceramic support body is polished smooth, and then rinsed with deionized water;

[0027] (2) Use a photoelectric analytical balance to measure 1g of PEBA particles, dissolve them in 19g of n-butanol, configure a PEBA film-forming solution with a mass fraction of 5%, and stir at a constant temperature of 70°C on a constant temperature electromagnetic stirrer for 3 hours until the formation of Uniform and transparent solution, then put the polymer solution in a water bath at a constant temperature of 60°C for 10 hours until there are no bubbles in the solution, and then use it;

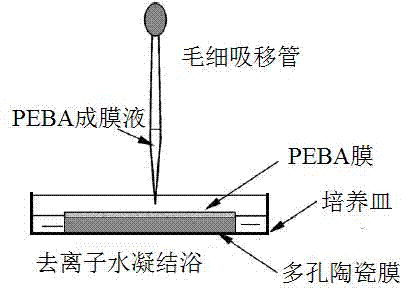

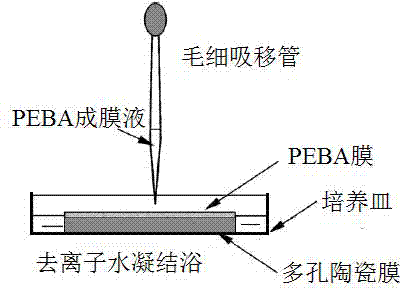

[0028] (3) As attached figure 1 , in a dust-free environment, the TiO 2 The ceramic membrane is placed in a petri dish, and deionized water is added to the petri dish to infiltrate TiO 2 The ceramic membrane surface shall prevail, and the water surface and TiO 2 Keep the thickness of the ceramic film even, let it stand until there is no disturbance on the water surface...

Embodiment 2

[0032] (1) For porous TiO 2 The ceramic support body is polished smooth, and then rinsed with deionized water;

[0033] (2) Use a photoelectric analytical balance to measure 1g of PEBA particles, dissolve them in 19g of n-butanol, configure a PEBA film-forming solution with a mass fraction of 5%, and stir at a constant temperature of 70°C on a constant temperature electromagnetic stirrer for 3 hours until the formation of Uniform and transparent solution, then put the polymer solution in a water bath at a constant temperature of 60°C for 10 hours until there are no bubbles in the solution, and then use it;

[0034] (3) As attached figure 1 , in a dust-free environment, the TiO 2 The ceramic membrane is placed in a petri dish, and deionized water is added to the petri dish to infiltrate TiO 2 The ceramic membrane surface shall prevail, and the water surface and TiO 2 Keep the thickness of the ceramic film at the same level, let it stand until the water surface is not disturbe...

Embodiment 3

[0038] According to the operation of implementation example 1, only changing the PEBA mass fraction in the PEBA film-forming liquid is 8%, obtains PEBA / TiO 2 Composite membrane, which is used to permeate and separate hexane / nitrogen mixed gas. When the molar fraction of hexane is 10% and the system temperature is 20°C, the hexane permeation rate is 103 (mol cm -2 ·s -1 ·Pa -1 ), the resolution is 30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com