Mesoporous macromolecule/silicon oxide nanocomposite with layered channel structure and preparation method thereof

A technology of nanocomposite materials and pore structure, which is applied in the preparation of microspheres, microcapsule preparations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Synthesis of Phenolic Resin Prepolymer

[0041] Melt 0.61g phenol at 40-42°C, add 0.13 g 20 wt% NaOH aqueous solution at this temperature and stir for 10 min, add 1.05 g 37wt% formaldehyde aqueous solution, raise the temperature to 70-75°C for 1 hour, cool down to room temperature, and use 0.6 mol / L HCl solution to adjust the pH value of the solution to 7.0, dehydration under vacuum and reduced pressure for 1 to 2 hours below 50°C. The obtained viscous liquid was dissolved in THF to prepare a 20 wt% solution for use.

Embodiment 2

[0042] Example 2 Preparation of As-made samples

[0043] Dissolve 0.5 g P123 and 0.5 g PDMS-PEO in 30.0 g tetrahydrofuran (THF) and stir at 40 °C for 10 min to obtain a uniform and transparent solution. Then 7.5 g of 20 wt % phenolic resin prepolymer ( M w <500) THF solution, stirred for 0.5h to obtain a homogeneous solution. Transfer the above solution to a petri dish, volatilize at room temperature for 5-8 h, and then place the petri dish in an oven at 100°C for 24 h to obtain a transparent orange-yellow film material. The above materials were scraped off the petri dish and ground into powder to obtain As-made samples.

[0044] The triblock copolymer P123 in this embodiment ( M w = 5800, EO 20 -PO 70 -EO 20 ) was purchased from Aldrich, PDMS-PEO ( M w =3012, DMS 32 -EO 20 ) were purchased from Shenzhen Merrill Chemical Technology Co., Ltd., and other reagents were purchased from Shanghai Chemical Reagent Company. All reagents were not further processed before ...

Embodiment 3

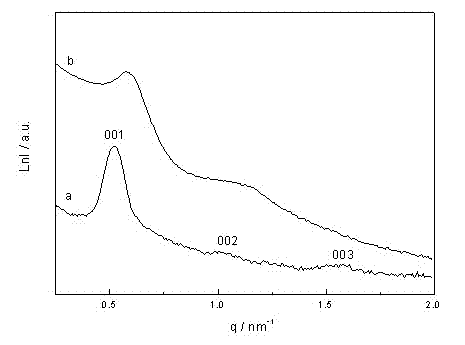

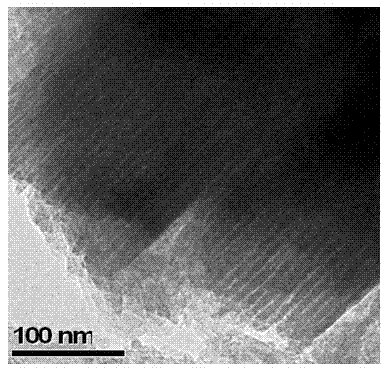

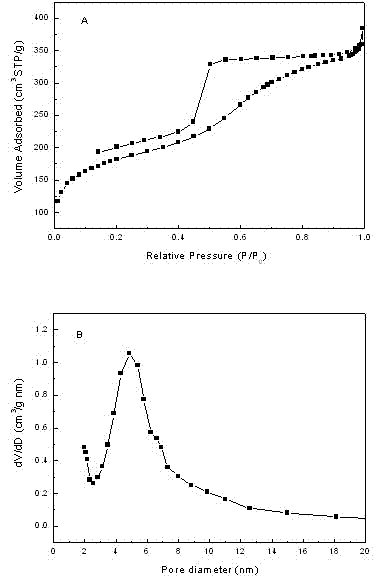

[0045] Example 3 Preparation of Mesoporous Polymer / Silicon Oxide Nanocomposites with One-dimensional Layered Pore Structure

[0046] The As-made sample was placed in a tube furnace for 3 h at 350 °C under the protection of nitrogen gas, and the heating rate was 5 °C / min. The obtained mesoporous polymer / silicon oxide nanocomposite sample is marked as MP-PS-350N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com