Method for preparing 5-methyl carboxylate-6-benzoltriazolylmethoxy

A technology of methoxybenzene and methyl carboxylate, applied in the field of organic compound synthesis, can solve problems such as unseen compound research reports, and achieve the effects of easy industrial production, good practicability, good economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

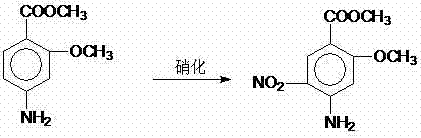

[0019] In the dry reaction flask, add 72.5g (0.4mol) methyl 2-methoxy-4-aminobenzoate, 140mL glacial acetic acid, 126g (1.23mol) acetic anhydride, stir to dissolve, heat up to 40°C, stir for 0.5 h, add 48ml (d=1.49) of nitric acid dropwise, stir at 40°C for 2h, after the reaction is complete, pour the reaction solution into 600ml of methanol containing 0.4mol of sulfuric acid, stir, add 1600g of ice water, precipitate crystals, filter, Dry to obtain 55.2 g of methyl 2-methoxy-4-amino-5-nitrobenzoate, mp=213.1~214.6°C.

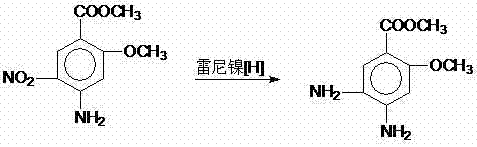

[0020] In the reaction kettle, add 2-methoxy-4-amino-5-nitrobenzoic acid methyl ester 555g (2.45mol), 30g Raney nickel, 2500mL methanol, at 50 ℃, 0.6Mpa hydrogen pressure, hydrogen Hydrogenation until the theoretical amount, the reaction is complete, cooled and filtered, washed with methanol. The solvent was recovered from the filtrate under reduced pressure. Cool to precipitate crystals, wash with methanol, and dry at 50°C to obtain 305g of methyl 2-methoxy-...

Embodiment 2

[0023] In the dry reaction bottle, add 72.5g (0.4mol) methyl 2-methoxy-4-aminobenzoate, 160mL glacial acetic acid, 138g (1.35mol) acetic anhydride, stir to dissolve, heat up to 40°C, stir for 0.5 h, add 52ml (d=1.49) of nitric acid dropwise, stir at 40°C for 2h, after the reaction is complete, pour the reaction solution into 600ml of methanol containing 0.4mol of sulfuric acid, stir, add 1600g of ice water, precipitate crystals, filter, After drying, 56.3 g of methyl 2-methoxy-4-amino-5-nitrobenzoate was obtained, mp=213.6~214.8°C.

[0024] In the reaction kettle, add 2-methoxy-4-amino-5-nitrobenzoic acid methyl ester 555g (2.45mol), 30g Raney nickel, 2500mL methanol, at 50 ℃, 0.8Mpa hydrogen pressure, pass Hydrogen hydrogenation until the theoretical amount, the reaction is complete, cooled and filtered, washed with methanol. The solvent was recovered from the filtrate under reduced pressure. Cool to precipitate crystals, wash with methanol, and dry at 50°C to obtain 312g o...

Embodiment 3

[0027] In a dry reaction flask, add 1mol 2-methoxy-4-aminobenzoic acid methyl ester, 4mol glacial acetic acid, 3.5mol acetic anhydride, stir to dissolve, heat up to 40°C, stir for 0.5h, add dropwise 2mol nitric acid (d = 1.49) dropwise, stirred at 40°C for 2h, and the reaction was completed, the reaction solution was poured into 1.5L of sulfuric acid-containing methanol (1mol / 1500ml), under stirring, an appropriate amount of ice water was added until crystals were precipitated, filtered, and dried to obtain 2 -Methoxy-4-amino-5-nitrobenzoic acid methyl ester, mp=213.1~214.6°C.

[0028] In the reaction kettle, add 450g of 2-methoxy-4-amino-5-nitrobenzoic acid methyl ester, 30g of Raney nickel, 1.8L of methanol, and hydrogenate at 50°C and 0.6Mpa hydrogen pressure until the theoretical When the reaction is complete, cool, filter, and wash with methanol. The solvent was recovered from the filtrate under reduced pressure. Cool to precipitate crystals, wash with methanol, and dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com