Quasi-three-level laser

A quasi-three-level laser technology, applied in lasers, laser components, phonon exciters, etc., can solve problems that affect the overall performance of quasi-three-level lasers, difficult to meet practical requirements, and low light-to-light conversion efficiency , to achieve the effect of solving the additional thermal effect, improving the light-to-light conversion efficiency, and reducing the thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

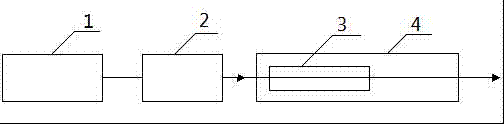

[0026] see figure 1 As shown, a quasi-three-level laser that realizes high-efficiency, low-threshold, and high-brightness 0.9X μm lasers, the device for realizing the method includes the following four parts: polarized pump light generation unit 1, beam shaping unit 2, gain medium Unit 3 and 0.9X μm optical cavity unit 4;

[0027] The polarized light generating unit 1 includes a polarized semiconductor laser, whose working mode is continuous working mode, the degree of polarization is 0.9, the maximum continuous pumping power is 30W, and the output wavelength is 808nm.

[0028] The beam shaping unit 2 includes a multimode optical fiber and a collimating and focusing lens group. Among them, the core diameter of the multimode fiber is 200 μm, and the numerical aperture NA=0.18; the collimating and focusing lens group is composed of 4 aspherical lenses, and the surface of the lens is coated with a film system with a transmittance of 99.5% at 808 nm, which can continuously adjust...

Embodiment 2

[0033] Roughly the same as Example 1, the differences are as follows:

[0034] (1) The polarized light generating unit 1 includes a conventional non-polarized semiconductor laser and a polarizer, which modulates the laser light emitted by the semiconductor laser into polarized light. Among them, the working mode of the semiconductor laser is continuous working mode, the maximum continuous pumping power is 40W, and the output wavelength is 808nm; the transmittance of the polarizer is 95% for p-wave and 2% for s-wave.

[0035] (2) The laser gain medium is traditional Nd:GdVO 4 Single crystal, the doping concentration is 0.2at.%, the size is 3×3×5 mm 3, the front and rear end faces are coated with anti-reflection coatings for beams with wavelengths of 808nm, 912nm, 1064nm and 1340nm, of which the transmittance of beams of 912nm and 1064nm is greater than 99.8%, and the transmittance of beams of 808nm and 1342nm is greater than 98%.

Embodiment 3

[0037] Roughly the same as Example 1, the differences are as follows:

[0038] (1) The polarized light generating unit 1 includes a polarized semiconductor laser, the working mode of which is continuous working mode, the degree of polarization is 0.9, the maximum continuous pumping power is 40W, and the output wavelength is 879nm.

[0039] (2) The laser gain medium is traditional Nd:LuVO 4 Ceramic, doping concentration 0.2at.%, size 3×3×6 mm 3 , the front and rear end faces are coated with anti-reflection coatings for beams with wavelengths of 879nm, 916nm, 1066nm and 1343nm, of which the transmittance of beams of 916nm and 1066nm is greater than 99.8%, and the transmittance of beams of 879nm and 1343nm is greater than 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Core diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com