Method for preparing electrospun composite nanoscale fiber felt containing nanoscale palladium particles

A technology of composite nanofibers and nanofibers, applied in fiber types, fiber treatment, textiles and papermaking, etc., can solve problems such as high viscosity, achieve the effects of small particle size, uniform distribution, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

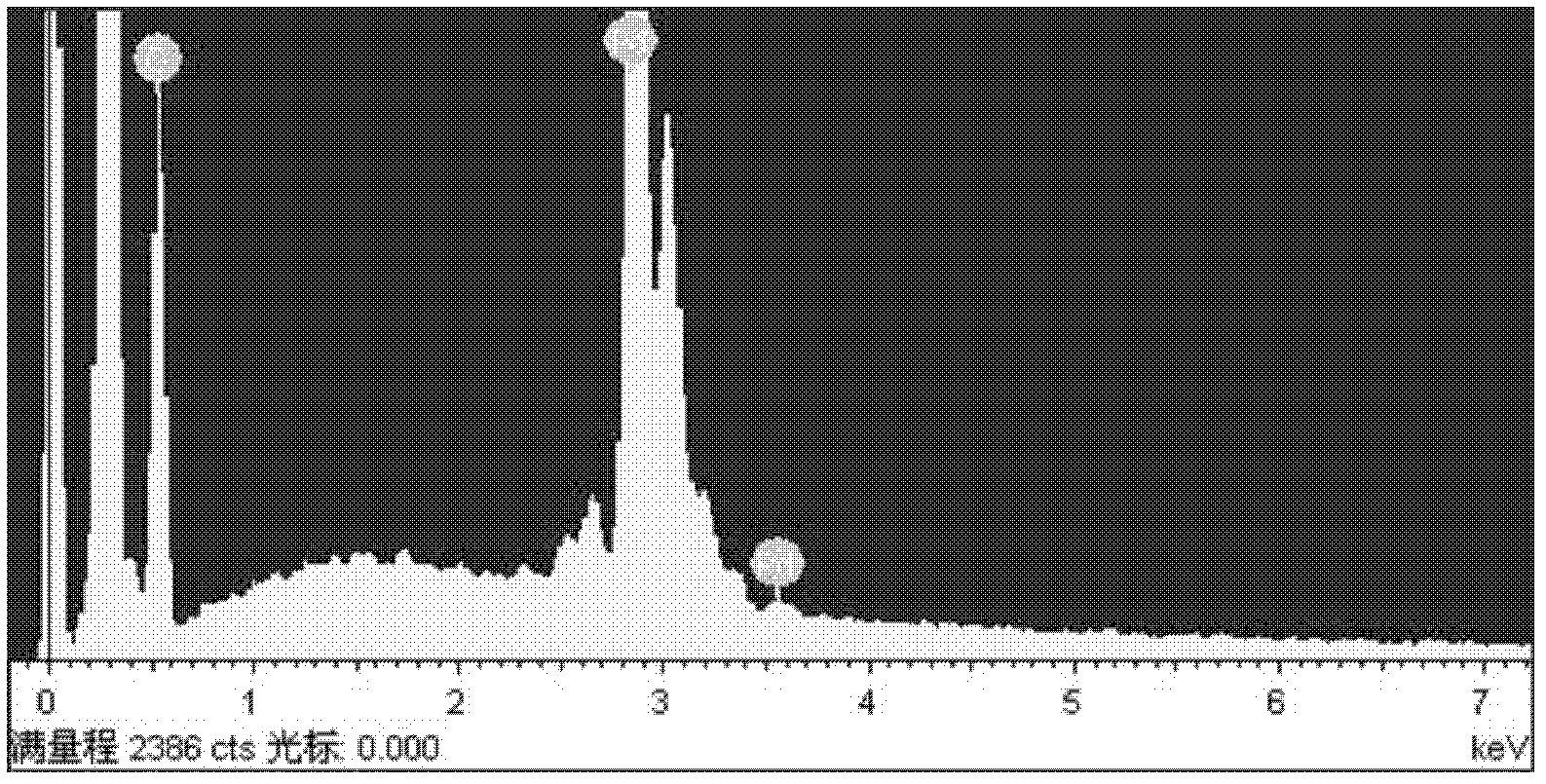

[0045] Take 8.141g of PVA powder and slowly add it to 60ml of deionized water, stir slowly for about 30 minutes until the PVA is completely swollen, then place it on a magnetic stirrer and stir in a water bath at 80°C for 3 hours to prepare a 12% mass percent PVA aqueous solution. After cooling To be used; take 26.112mgK 2 PdCl 4 Dissolve in 20ml deionized water to prepare a 4mM light brown solution; take 15.148mgNaBH 4 Dissolve in 20ml deionized water and prepare a 20mM aqueous solution for use.

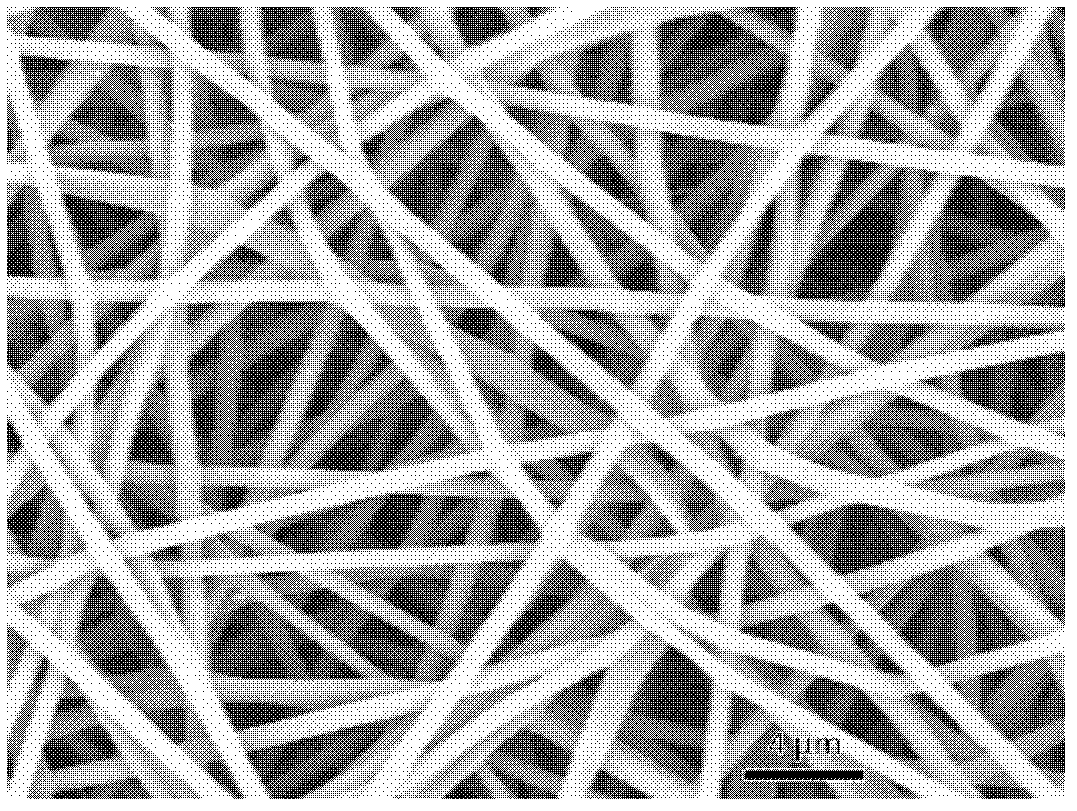

[0046] Weigh the PEI polyethyleneimine aqueous solution with a mass percentage concentration of 50% and the above-mentioned PVA aqueous solution to prepare a 10ml mixed solution with a total concentration of 12%, in which the mass ratio of PEI / PVA is 1:3; set spinning process conditions The flow rate is 0.3ml / h, the voltage is 18.6KV, and the receiving distance is 25cm. The prepared nanofibers are finally deposited on aluminum foil in the form of nanofiber mats. The fiber mats are dried...

Embodiment 2

[0051] Take 8.141g of PVA powder and slowly add it to 60ml of deionized water, stir slowly for about 30 minutes until the PVA is completely swollen, then place it on a magnetic stirrer and stir in a water bath at 80°C for 3 hours to prepare a 12% mass percent PVA aqueous solution. After cooling For use; take 13.056mgK 2 PdCl 4 Dissolve in 20ml deionized water to prepare 2mM light brown solution; take 25.246mgNaBH 4 Dissolve in 20ml deionized water and prepare a 12mM aqueous solution for use.

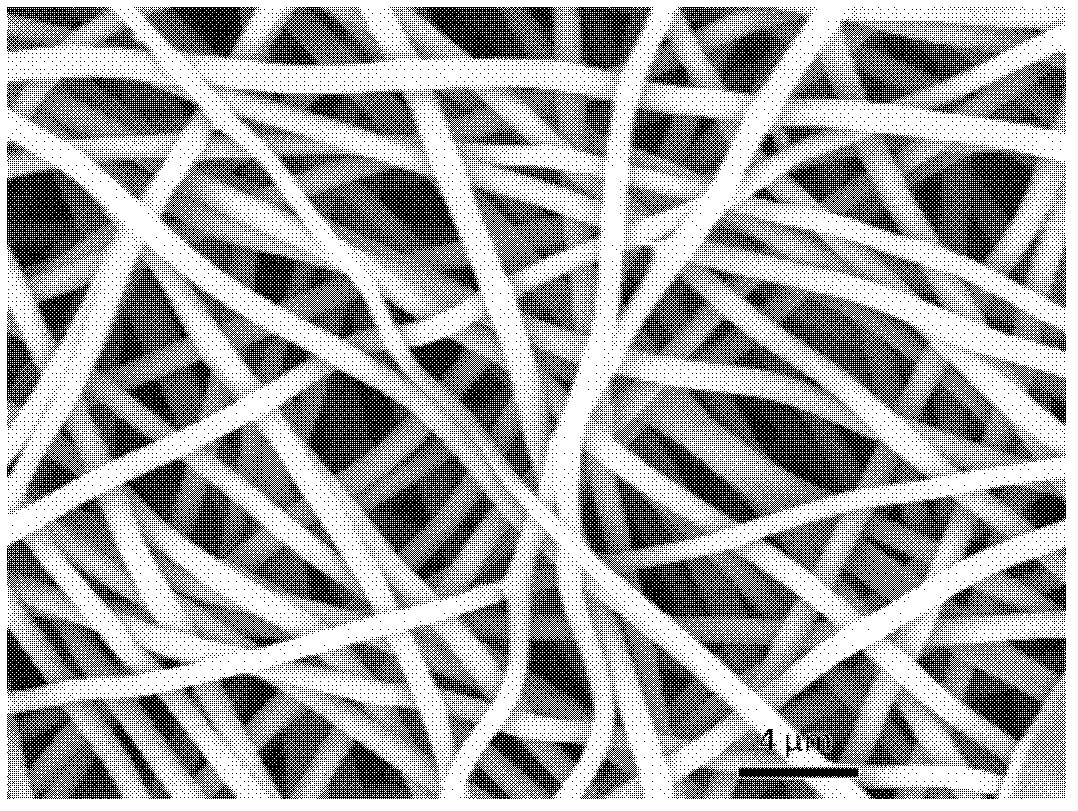

[0052] Weigh the PEI polyethyleneimine aqueous solution with a mass percentage concentration of 50% and the above-mentioned PVA aqueous solution to prepare a 10ml mixed solution with a total concentration of 8%, in which the mass ratio of PEI / PVA is 1:1; set the spinning process conditions The flow rate is 0.3ml / h, the voltage is 18.6KV, and the receiving distance is 25cm. The prepared nanofibers are finally deposited on aluminum foil in the form of nanofiber mats. The fiber mats are dried i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com