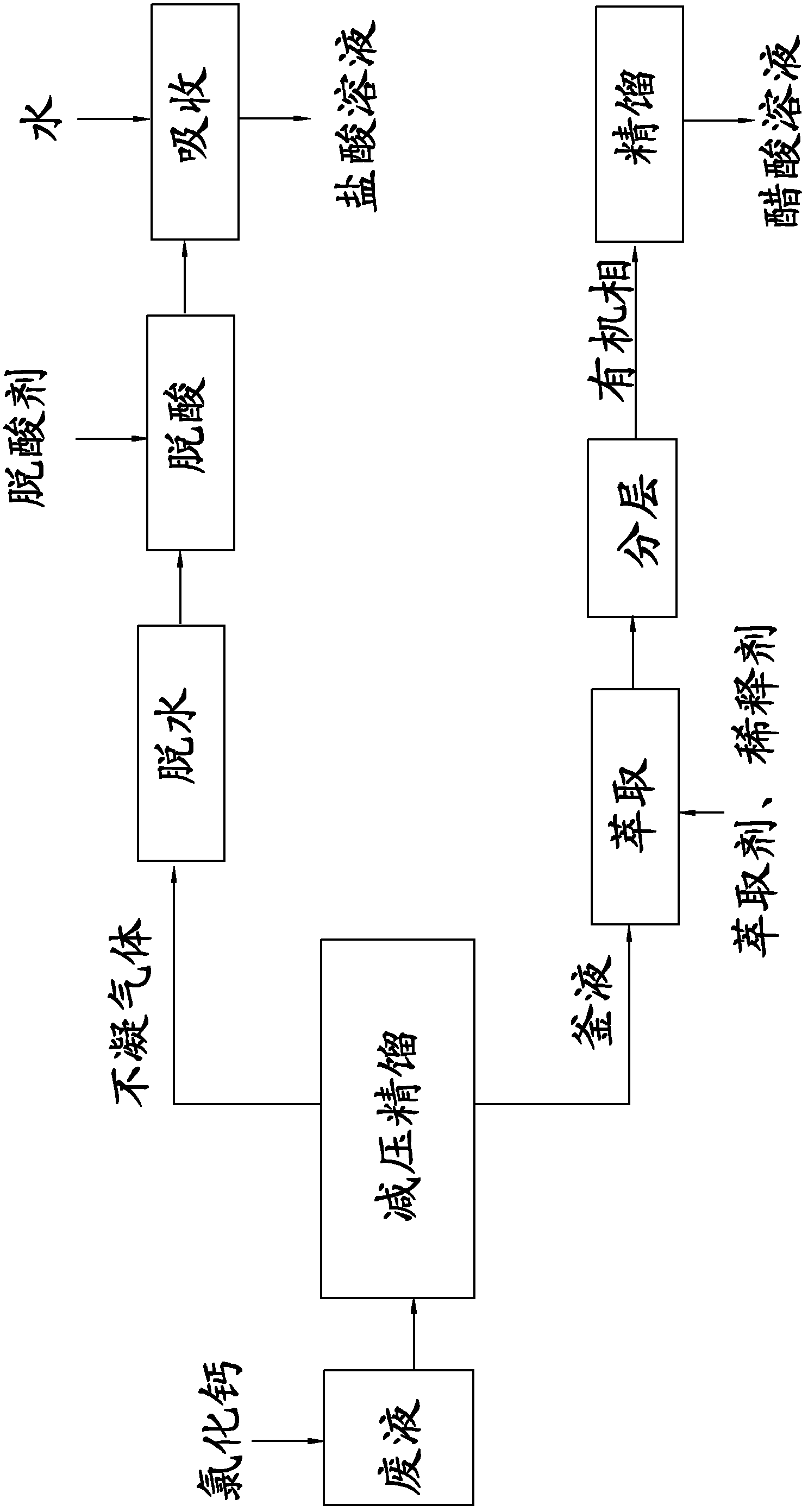

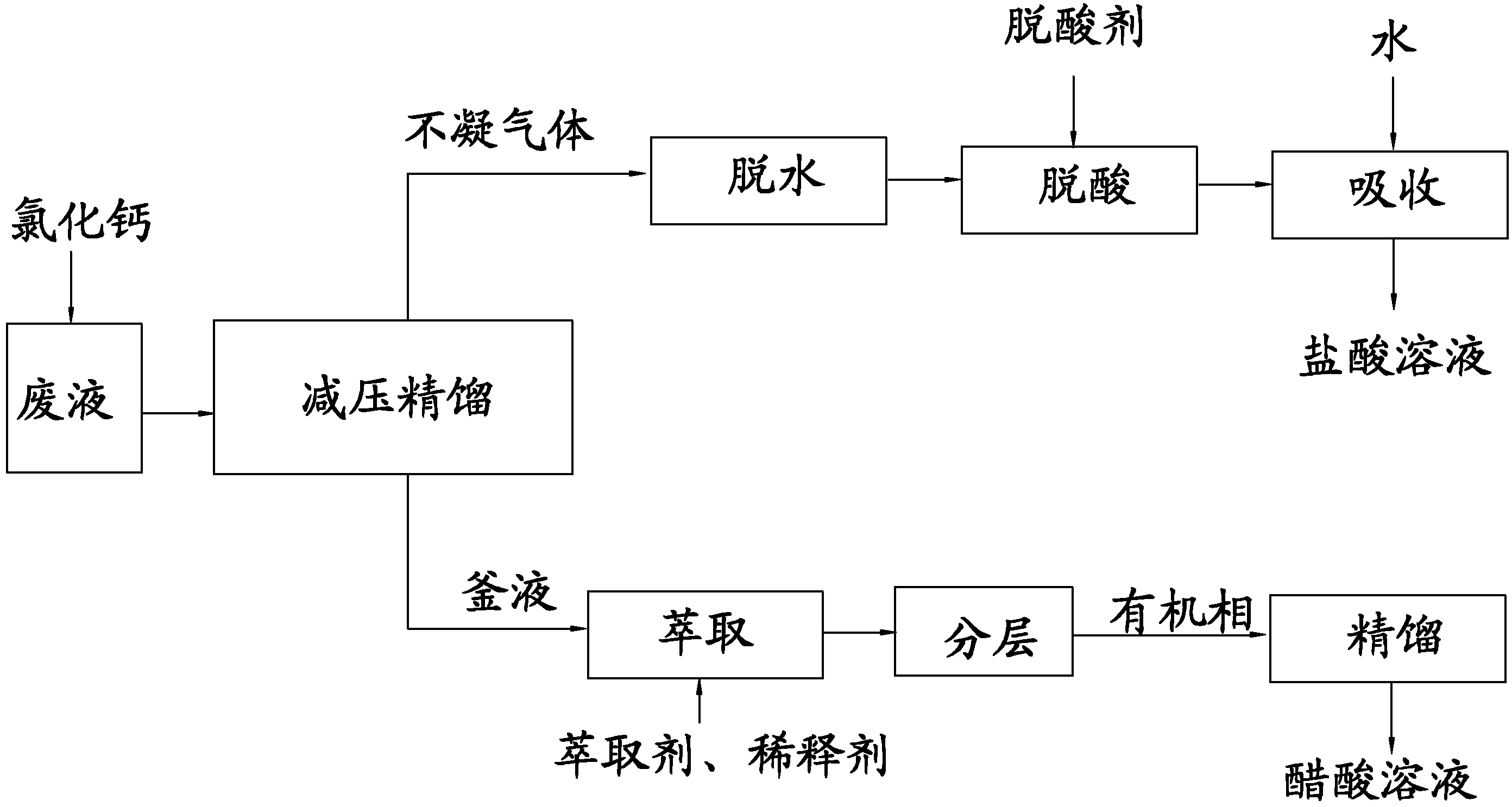

Recycling method of hydrochloric acid-acetic acid waste liquid

A technology of hydrochloric acid solution and acetic acid, applied in the field of medicine and chemical industry, can solve the problem of low concentration of hydrochloric acid solution and acetic acid solution, and achieve the effect of reducing labor intensity of workers, improving production safety and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1m of hydrochloric acid-acetic acid waste liquid produced in the process of producing D-glucosamine hydrochloride 3Joined in the reaction kettle, then added 200kg calcium chloride, stirred to make calcium chloride completely dissolved in the hydrochloric acid-acetic acid waste liquid, prepared into a distillation material, then, the above-mentioned prepared distillation material was pumped into the falling film tower. Inside, open the vacuum system, adjust the vacuum degree in the falling film tower to about 600mmHg column, after the system in the falling film tower is stable, gradually increase the vacuum degree and temperature in the falling film tower, so that the vacuum degree reaches 720mmHg column, the temperature When the temperature reaches 35°C, the vacuum degree and temperature are controlled, and rectification is carried out for 12 hours. During the rectification process, the evaporated gas is cooled by a condenser, and the cooled liquid is returned to the fal...

Embodiment 2

[0030] 1m of hydrochloric acid-acetic acid waste liquid produced in the process of producing D-glucosamine hydrochloride 3 Joined in the reaction kettle, then added 400kg calcium chloride, stirred to make calcium chloride completely dissolved in the hydrochloric acid-acetic acid waste liquid, prepared into a distillation material, then, the above-mentioned prepared distillation material was pumped into the falling film tower. Inside, open the vacuum system, adjust the vacuum degree in the falling film tower to about 600mmHg column, after the system in the falling film tower is stable, gradually increase the vacuum degree and temperature in the falling film tower, so that the vacuum degree reaches 700mmHg column, the temperature When the temperature reaches 40°C, the vacuum degree and temperature are controlled, and rectification is carried out for 10 hours. During the rectification process, the evaporated gas is cooled by the condenser, and the cooled liquid is returned to the ...

Embodiment 3

[0033] 1m of hydrochloric acid-acetic acid waste liquid produced in the process of producing D-glucosamine hydrochloride 3 Joined in the reaction kettle, then added 600kg calcium chloride, stirred to make the calcium chloride completely dissolved in the hydrochloric acid-acetic acid waste liquid, prepared into a distillation material, then, the above-mentioned prepared distillation material was pumped into the falling film tower. Inside, open the vacuum system, adjust the vacuum degree in the falling film tower to about 630mmHg column, after the system in the falling film tower is stable, gradually increase the vacuum degree and temperature in the falling film tower, so that the vacuum degree reaches 720mmHg column, the temperature When the temperature reaches 46°C, the vacuum degree and temperature are controlled, and rectification is carried out for 18 hours. During the rectification process, the evaporated gas is cooled by the condenser, and the cooled liquid is returned to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com