Supported organic rhenium catalyst and preparation method thereof

A catalyst and a supported technology, which are applied in the field of low-loaded and high-activity supported organic rhenium catalysts and their preparation, can solve the problems of restricting large-scale production and application, difficult separation and recovery of homogeneous catalysts, etc., and achieve high selectivity, high high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

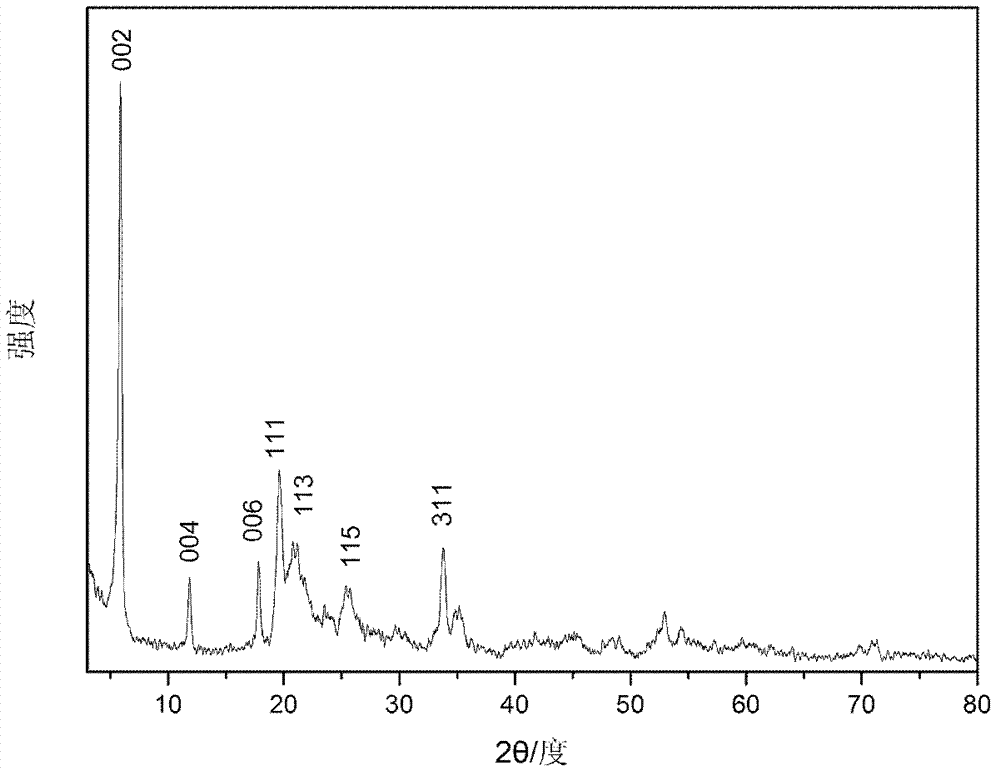

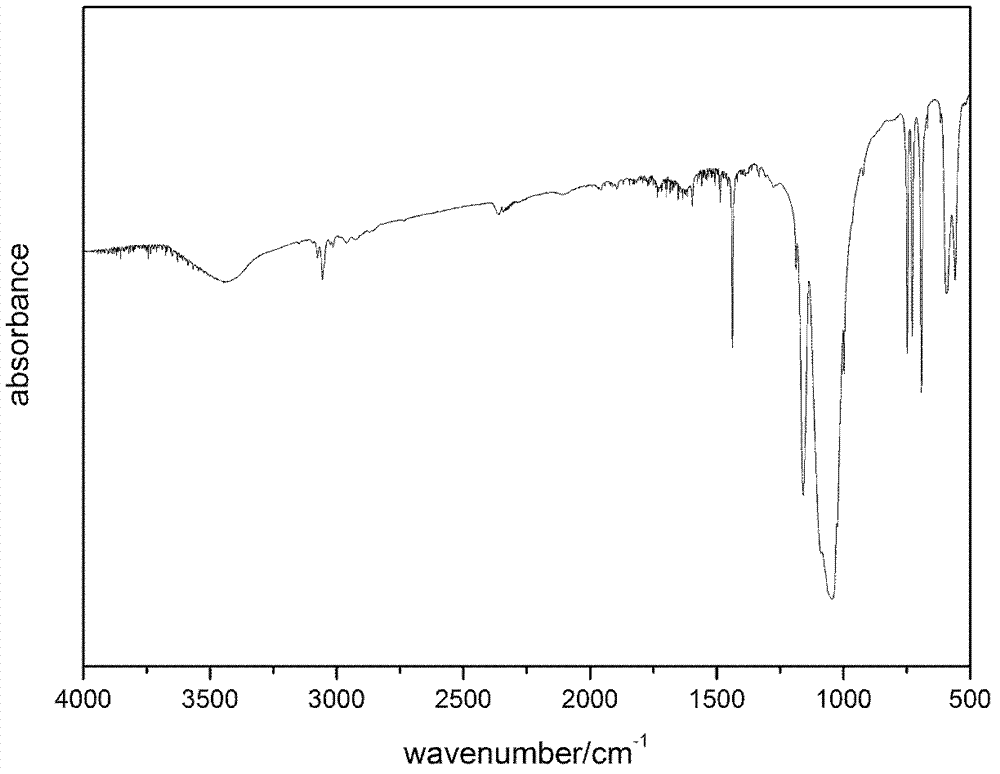

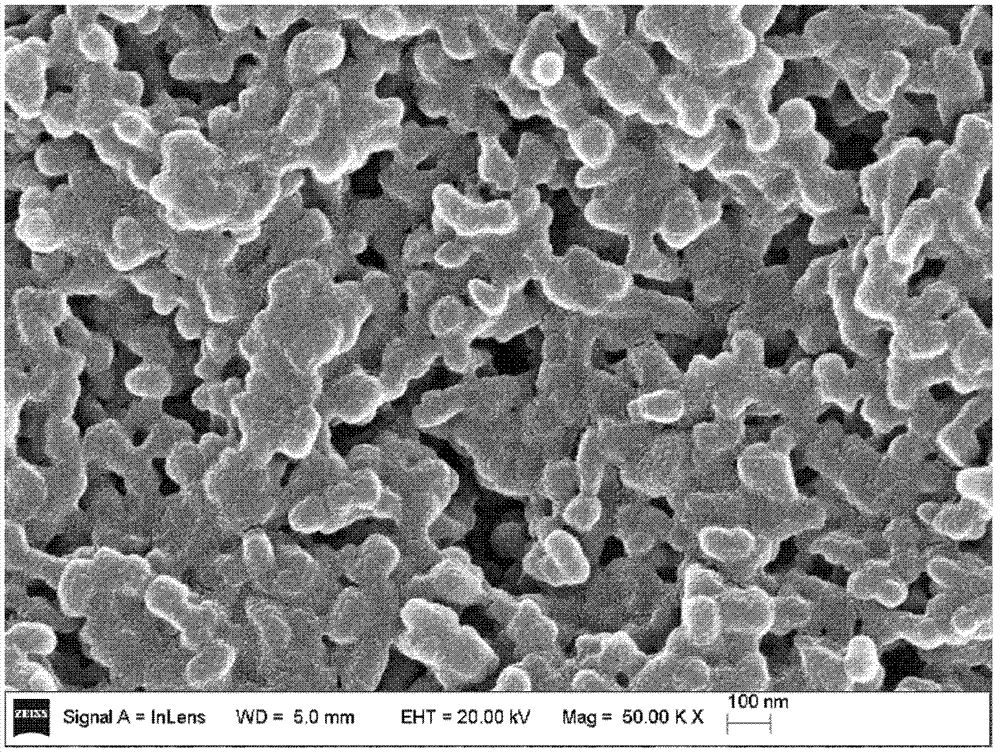

[0021] A: Weigh 14.50125g of ZrOCl 2 ·8H 2 Dissolve O in deionized water, add 6 mL of HF solution with a mass concentration of 40%, and finally dilute to 100 mL of mixed solution I; then weigh 14.2281 g of PhPO 3 , use 1-propanol and water with a volume ratio of 1:1 to prepare 100mL alcoholic aqueous solution II; use a dual-channel constant-current peristaltic pump to inject the mixed solution I and alcoholic aqueous solution II into the high-speed rotating fully back-mixed rotating fluid at the same speed In the membrane reactor, mix quickly for 1min, adjust the slit width between the rotor and the stator of the reactor to 0.04mm, the working voltage is 100V, and the rotor speed is 4000rpm; pour the prepared colloidal slurry into a hydrothermal kettle and heat at 100°C React for 96 hours; centrifuge and wash with a large amount of deionized water for 3 times until the pH is 7, wash once with isopropanol, once with acetone, once with ether, and then dry in a vacuum oven for 2...

Embodiment 2

[0025] A: with embodiment 1;

[0026]B: Measure 10mL of dichloromethane and add it to a 25mL three-necked flask, add 1.0g of the zirconium phosphate compound prepared in step A and 0.15g of MTO in sequence, 2 Under the protection of the atmosphere, use light-proof treatment, stir at room temperature for 24 hours, and the obtained powder is the supported organic rhenium catalyst; the active component of the catalyst, methyl rhenium trioxide, is evenly dispersed on the surface of the carrier zirconium phosphate compound;

[0027] C: Under the same reaction conditions as in Example 1, the catalytic performance of the catalyst prepared in step B was tested, the reactant cyclohexene conversion rate was 41.9%, the target product epoxy cyclohexane selectivity was 100%, and the TOF value of the catalyst was 40.9h -1 .

Embodiment 3

[0029] A: with embodiment 1;

[0030] B: with embodiment 1;

[0031] C: use the catalyst prepared in step B to catalyze the epoxidation of cyclooctene to generate epoxy cyclooctane, the reaction conditions are: reaction temperature 25°C, reaction pressure normal pressure, methanol as solvent, solvent consumption 10ml / 10mmol cyclooctene, Every milliliter of cyclooctene adds the catalyst that 0.1g step B obtains, and percarbamide consumption is 1.806g / mL cyclooctene, reaction time 6h, reactant cyclooctene conversion rate 88%, target product epoxy cyclooctane selectivity 100%, the TOF value of the catalyst is 29.7h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com