Method for refining carbidopa

A refining method and carbidopa technology, applied in the preparation of hydrazine, organic chemistry, etc., can solve the problems of increasing the refining cost of enterprises, reducing production efficiency, and low refining yield, and achieving low production cost, good economic benefits, and impurities. The effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

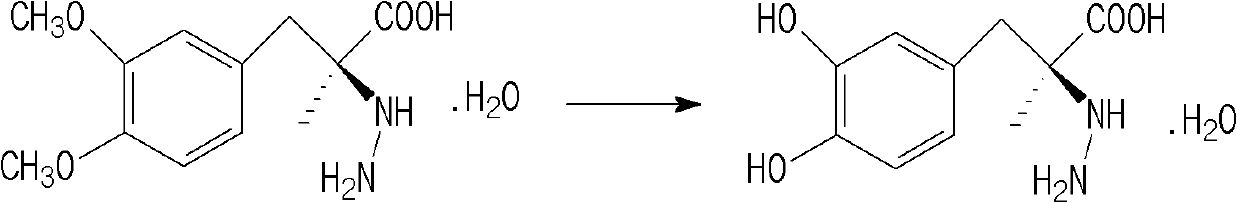

Image

Examples

preparation example 1

[0029] 100g of dimethylcarbidopa, add 1000g of hydrobromic acid with a mass percentage of 48%, heat to 120°C, react for 2h, distill off the hydrobromic acid under reduced pressure, add 100g of water, and use 1mol / L sodium hydroxide The pH of the aqueous solution was adjusted to 6.5, and a solid was precipitated, filtered and washed with water and dried in vacuum at 60°C for 4 hours to obtain 80.7 g of crude carbidopa. After detection by high performance liquid chromatography, the purity of carbidopa in the crude carbidopa was 96%. The purity of Quidopa is 2.8%.

Embodiment 1

[0037]1) add 2500g purified water in the reaction flask that stirring, thermometer, reflux device, heating device are housed, the carbidopa crude product that 50g preparation example 1 prepares (the purity of carbidopa is 96%, the purity of methyldopa Purity is 2.8%), under the condition of nitrogen protection, start stirring (300 rev / min), adjust with DL-malic acid (D-type and L-type each account for 50%, analytically pure, Shanghai Boao Biotechnology Co., Ltd.) pH to 3.0, stirred and heated to 98°C±1°C, dissolved to obtain the crude product system;

[0038] 2) Add 2 g of medicinal activated carbon (the specification is that the methylene blue adsorption value is greater than 13 mL) to the crude product system obtained in step 1), and decolorize at 100° C. for 60 minutes under the condition of nitrogen protection;

[0039] 3) After decolorization, filter while hot to obtain the filtrate. Under the condition of nitrogen protection, transfer the filtrate to a nitrogen-protected...

Embodiment 2

[0043] 1) add 2000g purified water in the reaction bottle that stirring, thermometer, reflux device, heating device are housed, the carbidopa crude product that 50g preparation example 1 prepares (the purity of carbidopa is 96%, the purity of methyldopa Purity is 2.8%), start stirring (300 rev / min), adjust pH to 3.0 with DL-malic acid (50% each of D-type and L-type, analytically pure, Shanghai Boao Biotechnology Co., Ltd.), under nitrogen protection Under the condition of stirring and heating to 98°C±1°C, dissolve to obtain the crude product system;

[0044] 2) Add 2 g of medicinal activated carbon (the specification is that the methylene blue adsorption value is greater than 13 mL) to the crude product system obtained in step 1), and decolorize at 100° C. for 60 minutes under the condition of nitrogen protection;

[0045] 3) After decolorization, filter while hot to obtain the filtrate. Under the condition of nitrogen protection, transfer the filtrate to a nitrogen-protected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com