Composite heat stabilizer for polyvinyl chloride (PVC), and preparation method for composite heat stabilizer

A composite heat stabilizer and stabilizer technology, applied in the chemical industry, can solve the problems of not getting rid of the dependence on lead salt stabilizers, and achieve the effects of reducing operator poisoning, reducing production costs, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

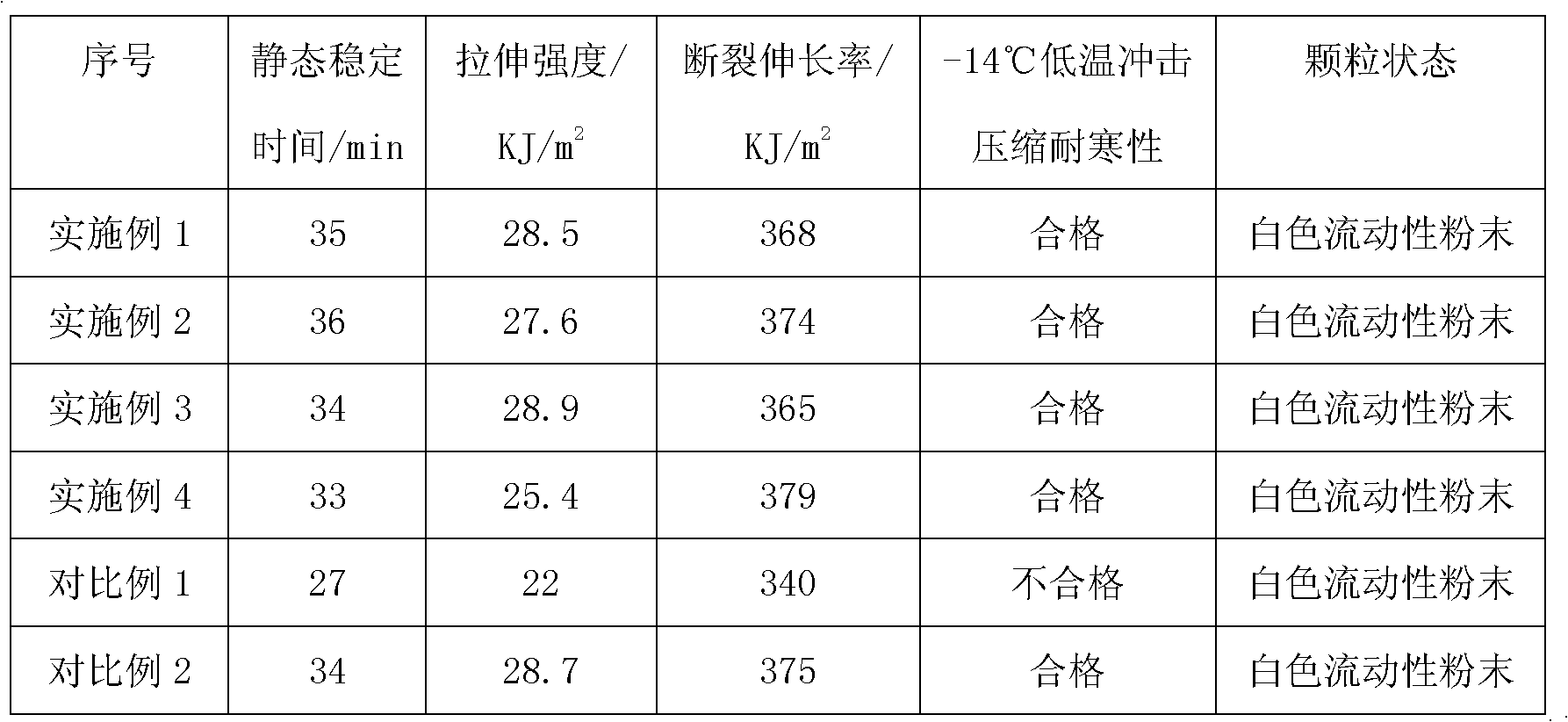

Examples

Embodiment 1

[0024] 1. Prepare the main stabilizer 3-dodecylmercaptopropionic acid metal soap stabilizer according to the following formula and method:

[0025] Formula: 100 parts of acrylic acid, 250 parts of a mixed solvent formed by mixing absolute ethanol and isopropanol with a mass ratio of 1:1, 160 parts of sodium hydroxide solution with a mass fraction of 37.5%, 255 parts of n-dodecanethiol, mass The fraction is 26.74% chloride (Ca 2+ / Zn 2+ The molar ratio is 2:1) solution 273 parts, deionized water 200 parts.

[0026] Preparation method: 250 parts of a mixed solvent obtained by mixing 100 parts of acrylic acid, absolute ethanol and isopropanol at a ratio of 1:1 is added to the reaction kettle, 160 parts of sodium hydroxide solution with a mass fraction of 37.5% is added dropwise, and the temperature is controlled at 35 Between ~40°C, the controlled dropping time is about 2 hours; then slowly add 255 parts of n-dodecanethiol dropwise, the controlled dropping time is about 3 hours...

Embodiment 2

[0031] Except that in step 1, the solvent was replaced with 250 parts of mixed solvents formed by mixing n-propanol and absolute ethanol with a mass ratio of 1:1, all the others were the same as in Example 1.

Embodiment 3

[0033] Except that in step 2, the phosphite compound was replaced by 3 parts of phenylenedi-isooctyl phosphite, the rest were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com