Solid acid catalyst for preparing biodiesel and preparation method thereof

A solid acid catalyst, biodiesel technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. The problem of high water volume can achieve the effect of large ion exchange capacity, high catalytic activity and improved catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Preparation of sulfonated phenylphosphonic acid. Will SO 3 Liquid (12.5cm 3 ) was slowly added into the round bottom flask containing phenylphosphoric acid (20g, 127mmol) and 1,2-dichloroethane (100ml) at a temperature of 0°C, the liquid gradually changed from colorless to yellow, and the round bottom flask was heated at 90 ℃ water bath and heated to reflux for 14 hours to obtain a two-phase liquid, the upper layer was colorless 1,2-dichloroethane, and the lower layer was yellow viscous crude product of sulfonated phenylphosphoric acid. Remove the supernatant 1,2-dichloroethane liquid, dissolve the resulting crude product in deionized water, add 15% BaCl 2 solution to remove excess sulfuric acid, centrifuge to remove BaSO 4 Precipitation, the filtrate was added to a cation exchange resin for ion exchange for 24 hours, and suction filtered. The obtained filtrate was concentrated by a rotary evaporator and then extracted repeatedly with ether until the extracted ether ...

Embodiment 2

[0056] Preparation method of sulfonated phenylphosphonic acid with different degrees of sulfonation. The preparation method of the sulfonated phenylphosphonic acid of different sulfonation degree is the same as embodiment 1, just increases SO 3 The dosage, raising reaction temperature, increasing reaction time etc. methods realizes. This allows the preparation of sulfonated phenylphosphonic acids with a degree of sulfonation greater than 100%. The degree of sulfonation is between 100% and 200%.

[0057] For example, when the dosage of phenylphosphonic acid is 20g, the liquid SO 3 The dosage is 35mL, the reaction temperature is 95°C, the reaction is 24h, and the sulfonated phenylphosphonic acid with a sulfonation degree of 200% can be obtained.

[0058] When the dosage of phenylphosphonic acid is 20g, the liquid SO 3 The dosage is 30mL, the reaction temperature is 90°C, and the reaction is 15h, and the sulfonated phenylphosphonic acid with a sulfonation degree of 170% can b...

Embodiment 3

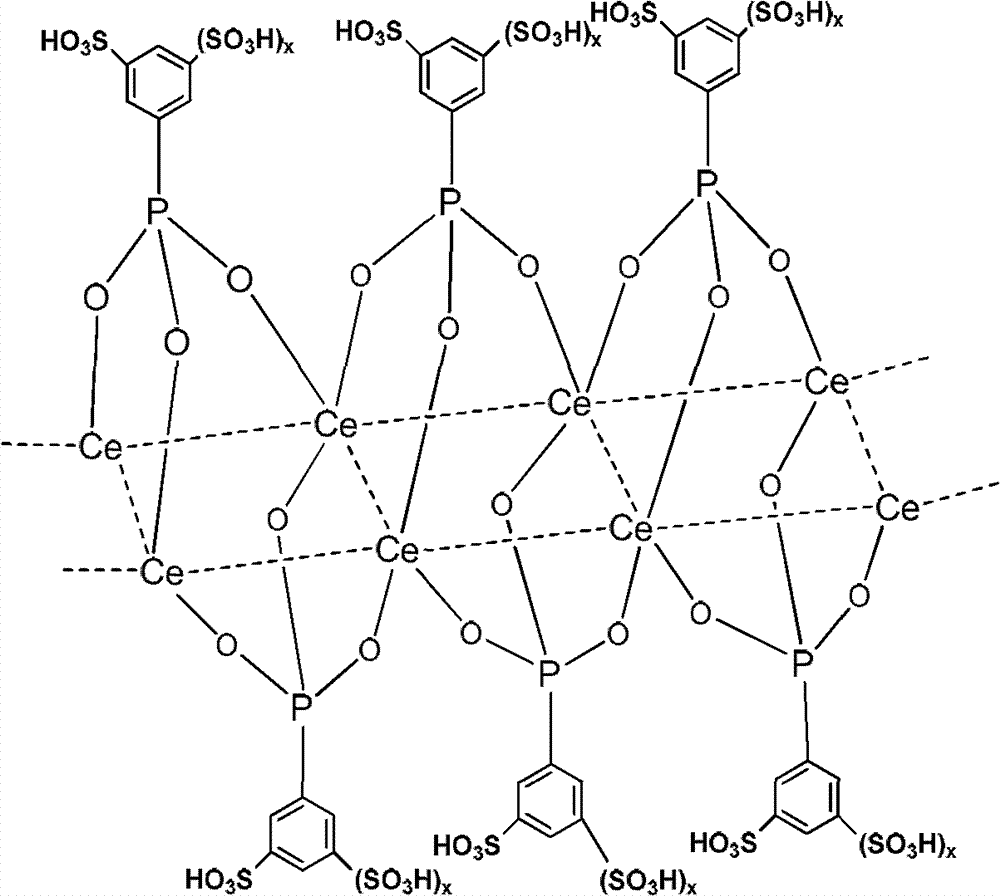

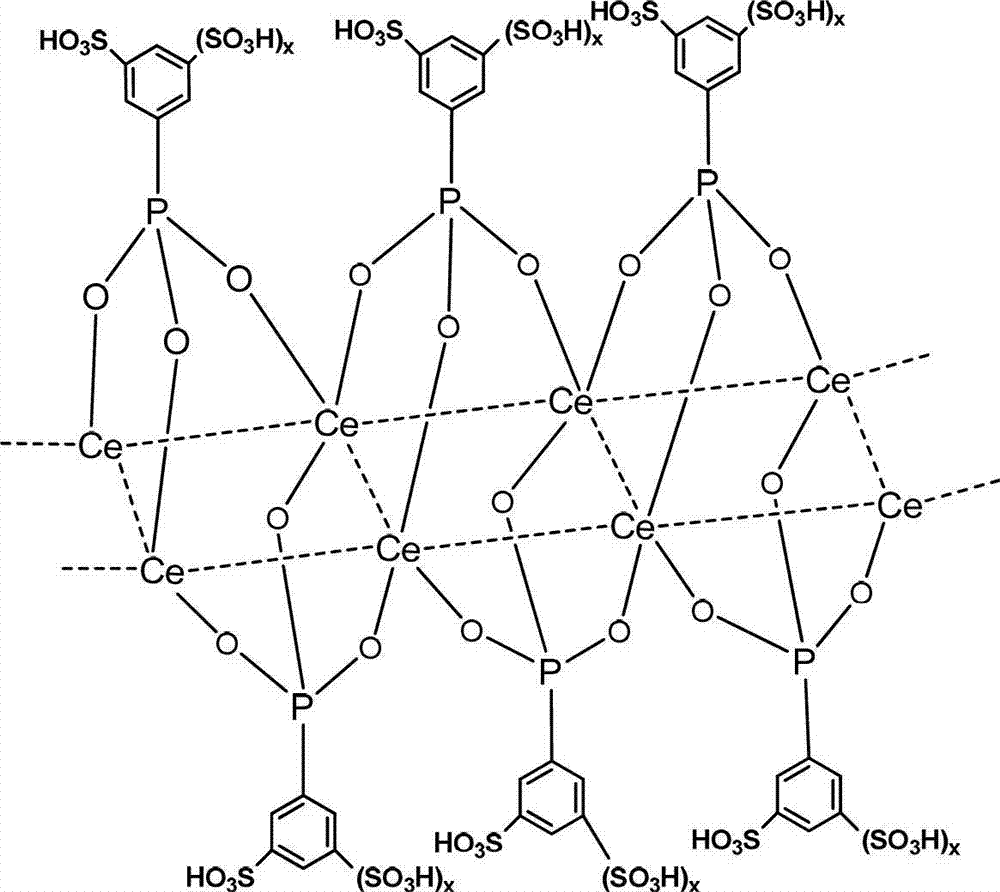

[0060] Preparation of cerium sulfonated phenylphosphonate (CeSPP). Get ceric ammonium nitrate (10g, 18.24mmol) and add in the beaker, add 1mol L -1 nitric acid solution until completely dissolved. The dissolved solution was added to the solution of sulfonated phenylphosphonic acid (100% sulfonation degree) (4.5g, 18.24mmol), the solution immediately turned into a yellow emulsion, heated and stirred at 80°C for 12h and centrifuged, and the centrifuged The precipitate was washed repeatedly to remove the soluble acid therein to obtain a light yellow powder, which was dried to obtain a yellow CeSPP powder with a yield of about 72%. The degree of sulfonation is 100%.

[0061] The degree of sulfonation of the product is determined by the degree of sulfonation of the reaction raw material sulfonated phenylphosphonic acid, the sulfonated phenylphosphonic acid of which degree of sulfonation is used as raw material (DS=x), the sulfonated sulfonated phenylphosphonic acid cerium obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com