Tire

A tire and sidewall technology, applied in special tires, tire parts, tire sidewalls, etc., can solve the problem that the low loss effect of carbon black filler is not sufficient, and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

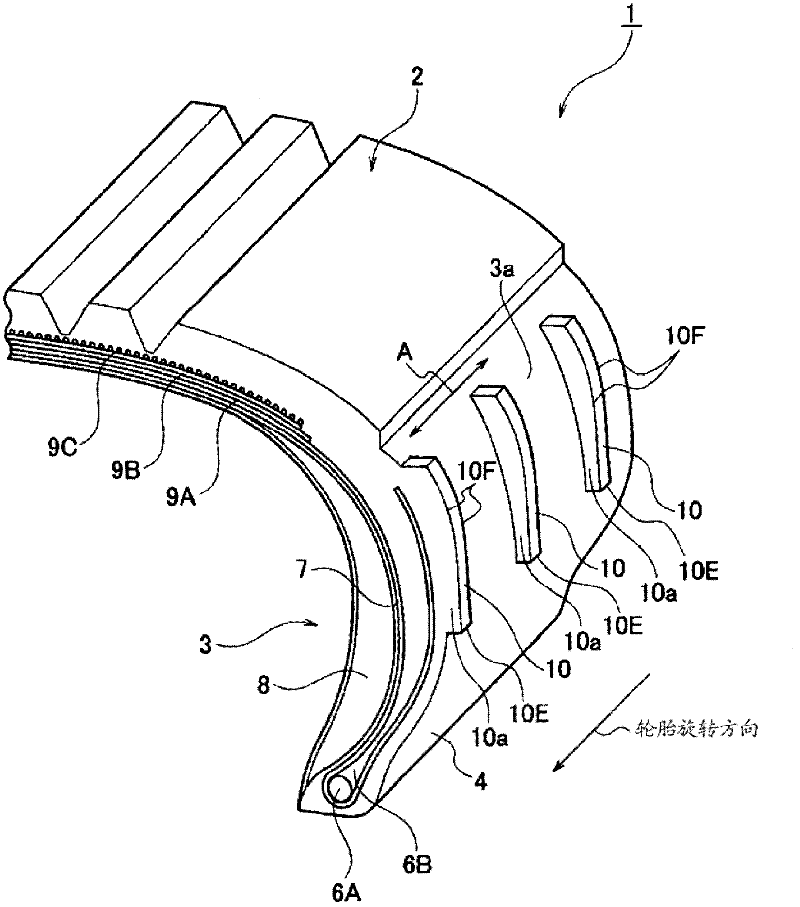

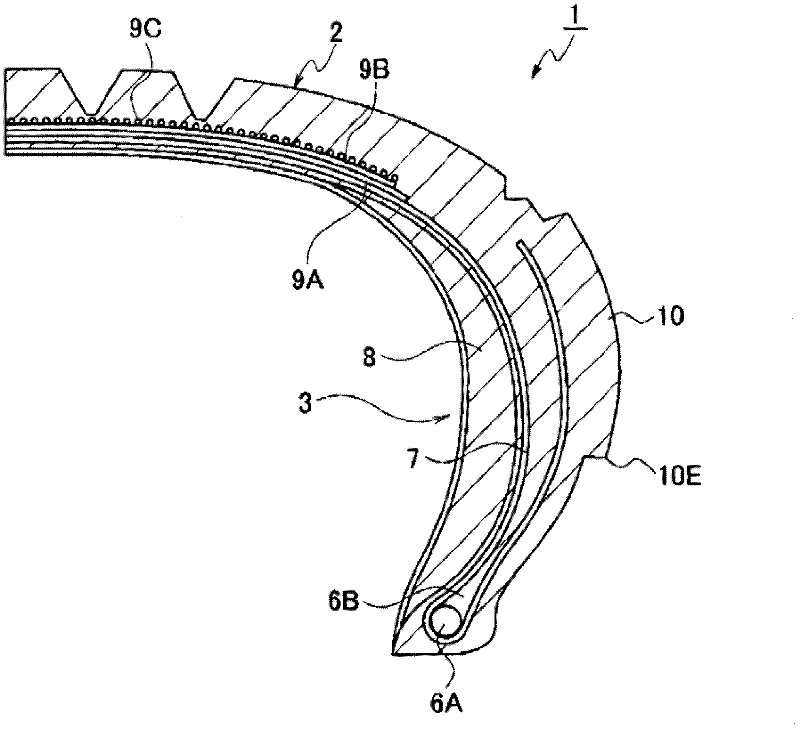

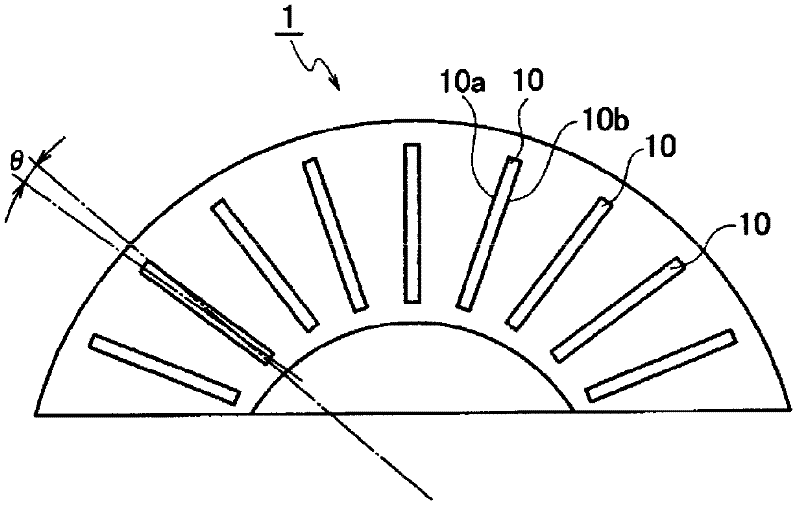

[0152] In the above-described embodiment, the turbulent flow generating protrusion 10 is provided on the entire periphery of the side wall portion 3 , but the turbulent flow generating protrusion 10 may be provided only in a part of the side wall portion 3 .

[0153] In the above embodiment, the turbulent flow generating protrusions 10 are provided at equal intervals in the tire circumferential direction of the sidewall portion 3 , but the turbulent flow generating protrusions 10 may be provided at uneven intervals in the tire circumferential direction.

[0154] In addition, the angle of the direction of the turbulent flow generation protrusion 10 with respect to the radial direction may be constant. In a rotating pneumatic tire, since the flow velocity of the air flow varies according to the radial position, for the purpose of improving heat dissipation, The angle formed by the direction of the turbulence-generating protrusion 10 with respect to the radial direction may also b...

Embodiment

[0164] Next, the present invention will be described in more detail through examples, but the present invention is not limited by these examples.

[0165] In addition, the physical properties of the unmodified or modified conjugated diene polymer, carbon black, and unvulcanized rubber composition, and the run-flat durability and rolling resistance of the tire were measured by the following methods.

[0166] "Physical Properties of Unmodified or Modified Conjugated Diene Polymers"

[0167]

[0168] It is measured by GPC [manufactured by Tosoh Corporation, HLC-8220] using a refractometer as a detector, and is expressed in terms of polystyrene with monodisperse polystyrene as a standard. In addition, the column was GMHXL [manufactured by Tosoh Corporation], and the eluent was tetrahydrofuran.

[0169]

[0170] Treat the sample with a siloxane hydrolysis reagent formed from 0.2N toluenesulfonic acid / 0.24N water in a solvent containing 15% by mass n-butanol and 85% by mass tol...

manufacture example 1

[0191] Production Example 1: Production of Polymer A

[0192] In a nitrogen-purged 5 L autoclave, under nitrogen, 1.4 kg of cyclohexane, 250 g of 1,3-butadiene, 2,2-bis(tetrahydrofuryl)propane (0.0285 mmol) were injected as a cyclohexane solution, 2.85 mmol of n-butyllithium (BuLi) was added thereto, and then polymerization was performed for 4.5 hours in a 50° C. warm water bath provided with a stirring device. The reaction conversion of 1,3-butadiene was substantially 100%. Add 1.3g of 2,6-di-tert-butyl-p-cresol methanol solution to the polymer solution to stop the polymerization, then remove the solvent by stripping, and dry with a roll at 110°C to obtain polymer A (co- conjugated diene polymers). The molecular weight (Mw) and molecular weight distribution (Mw / Mn) of the polymer taken out before the termination of the polymerization of the obtained polymer A were measured. The results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com