Method of preparing methanol through metal hydrothermal reduction of formic acid

A technology of formic acid and methanol, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as incomplete combustion or biomass gasification, dependence on non-renewable energy, unfavorable industrialization, etc., and achieve low cost , broad development prospects and application space, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

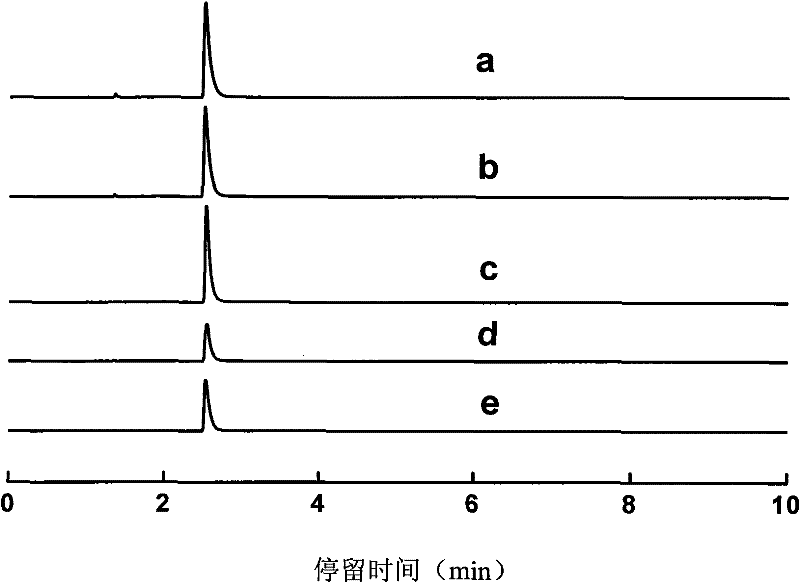

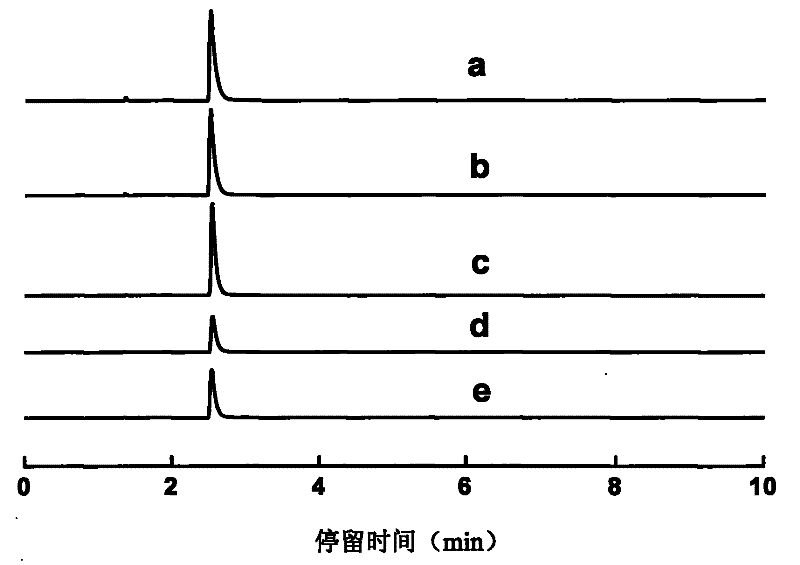

[0023] Put the formic acid solution, copper powder and zinc powder into the SUS316 reaction tube, so that the filling rate reaches 35%, seal the reaction tube, put it in a salt bath at 300°C, the pressure is the corresponding saturated vapor pressure, and react for 7 hours. The product is analyzed by gas chromatography / hydrogen flame ion detector (GC-FID), and the spectrogram is as follows: figure 1 As shown in the middle curve a, the peak is methanol.

[0024] This method can be used to realize the conversion of formic acid to methanol products, and then use alkaline waste water or NaOH solution to adjust the pH of the product solution to 8, the formic acid in the solution is converted into formate, and the methanol in the liquid phase product is removed by distillation or rectification. Separation, the residual formate solution is used as the reactant of the next reaction, recycled, and can also enter the sewage treatment plant treated by traditional biological methods to su...

Embodiment 2

[0026] Put the formic acid solution, copper powder and aluminum powder into the SUS316 reaction tube, so that the filling rate reaches 35%, seal the reaction tube, put it in a salt bath at 300 ° C, the reaction pressure is the corresponding saturated vapor pressure, and react for 7 hours. The phase product was analyzed by gas chromatography / hydrogen flame ionization detector (GC-FID), and the spectrogram was as follows figure 1 As shown in the middle curve b, the peak is methanol.

[0027] This method can be used to realize the conversion of formic acid to methanol products, and then use alkaline waste water or NaOH solution to adjust the pH of the product solution=9, the formic acid in the solution is converted into formate, and the methanol in the liquid phase product is removed by distillation or rectification. Separation, the residual formate solution is used as the reactant of the next reaction, recycled, and can also enter the sewage treatment plant treated by traditiona...

Embodiment 3

[0029] Put the formic acid solution, nickel powder and zinc powder into the SUS316 reaction tube to make the filling rate reach 35%, then seal the reaction tube, put it in an oven at 180°C, the reaction pressure is the corresponding saturated vapor pressure, and react for 12 hours. Gas chromatography / hydrogen flame ionization detector (GC-FID) analysis is carried out to liquid phase product, and spectrogram is as follows figure 1 As shown in the middle curve c, the peak is methanol.

[0030] This method can be used to realize the conversion of formic acid to methanol products, and then use alkaline waste water or NaOH solution to adjust the pH of the product solution=9, the formic acid in the solution is converted into formate, and the methanol in the liquid phase product is removed by distillation or rectification. Separation, the residual formate solution is used as the reactant of the next reaction, recycled, and can also enter the sewage treatment plant treated by traditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com