Synthesis method of 3-chloro-2-hydroxypropyl-trimethyl ammonium chloride based on solid base catalysis system

A technology of trimethylammonium chloride and catalytic system is applied in chemical instruments and methods, preparation of aminohydroxy compounds, preparation of organic compounds, etc., and can solve the problems of poor thermal stability, high cost, complicated preparation, etc. The effect of easy adjustment of pH value, short reaction time and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

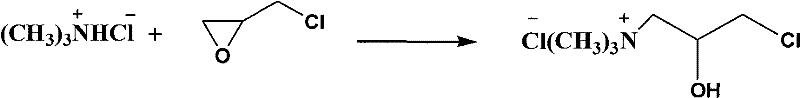

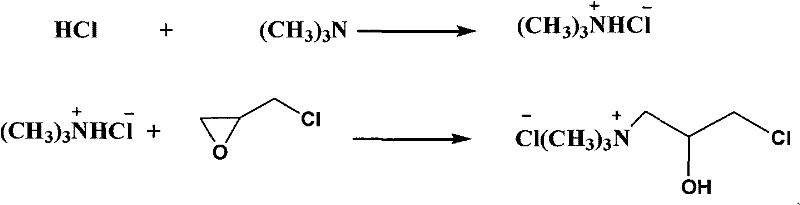

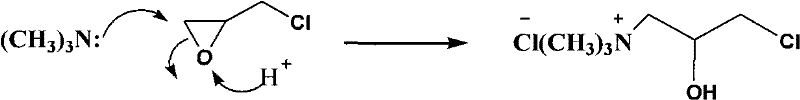

Method used

Image

Examples

Embodiment 1

[0033] Liquid-phase 3-chloro-2-hydroxypropyl-trimethylammonium chloride synthesis:

[0034] Add 70 g of trimethylamine hydrochloride and 64 ml of water in turn into the reaction flask, start stirring until the trimethylamine hydrochloride is completely dissolved, then add 10 g of catalyst ZnO to keep the pH of the system at 7.8. Cool down to 5°C and start adding 66g of ECH dropwise. After dropping, keep warm until: 1) the pH value of the system reaches a peak value of 9.7; 2) the system becomes homogeneous and ends. Filter and remove catalyzer to obtain crude product, crude product adds 4 times of volumes of deionized water (adding in 8 times), controls vacuum at 740mmHg, and temperature carries out continuous stripping underpressure distillation at 48 ℃, obtains solid content: 68.9% ( mass percent); active substance content: 97.7%, ECH content: ≤ 13ppm (GC); dichloroisopropanol (DCP) content: ≤ 29ppm (GC) liquid product.

Embodiment 2

[0036] Liquid-phase 3-chloro-2-hydroxypropyl-trimethylammonium chloride synthesis:

[0037] Add 70g of trimethylamine hydrochloride and 60ml of water in turn into the reaction flask, start stirring until the trimethylamine hydrochloride is completely dissolved, then add 7g of ZnO / KF composite catalyst to keep the pH of the system at 8. Cool down to 2° C. and add 67 g of ECH dropwise. After dropping, keep warm until: 1) the pH value of the system reaches a peak value of 11; 2) the system becomes homogeneous and ends. Filtration removes catalyst to obtain crude product, and crude product adds 6 times of volumes of deionized water (adding in 10 times), controls vacuum at 760mmHg, and carries out continuous stripping and vacuum distillation at 75° C. to obtain solids content: 70.1% ( mass percent); active substance content: 98.0%, ECH content: ≤ 5ppm (GC); dichloroisopropanol (DCP) content: ≤ 20ppm (GC) liquid product.

Embodiment 3

[0039] Liquid-phase 3-chloro-2-hydroxypropyl-trimethylammonium chloride synthesis:

[0040] Add 70g of trimethylamine hydrochloride and 70ml of water in sequence in the reaction bottle, start stirring until the trimethylamine hydrochloride is completely dissolved, then add ZnO and / K 2 CO 3Composite catalyst 14g, keep the pH value of the system at 8. Cool down to 0° C. and add 68 g of ECH dropwise. After dropping, keep warm until: 1) the pH value of the system reaches a peak value of 9.5; 2) the system becomes homogeneous and ends. Filter and remove catalyzer to obtain crude product, crude product adds 8 times of volumes of deionized water (adding in 10 times), controls vacuum at 750mmHg, and temperature carries out continuous stripping and vacuum distillation at 80° C. to obtain solids content: 70% ( mass percent); active substance content: 98.8%, ECH content: ≤ 5ppm (GC); dichloroisopropanol (DCP) content: ≤ 22ppm (GC) liquid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com