A kind of flexible magnet without dropping magnetic powder and preparation method thereof

A flexible magnet and magnetic powder technology, applied in the direction of magnetic objects, magnets, inorganic materials, etc., can solve the problems of magnetic powder loss of flexible bonded magnets, affecting product dimensional accuracy, complex manufacturing process, etc., to increase surface finish and solve the problem of magnetic powder removal , the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

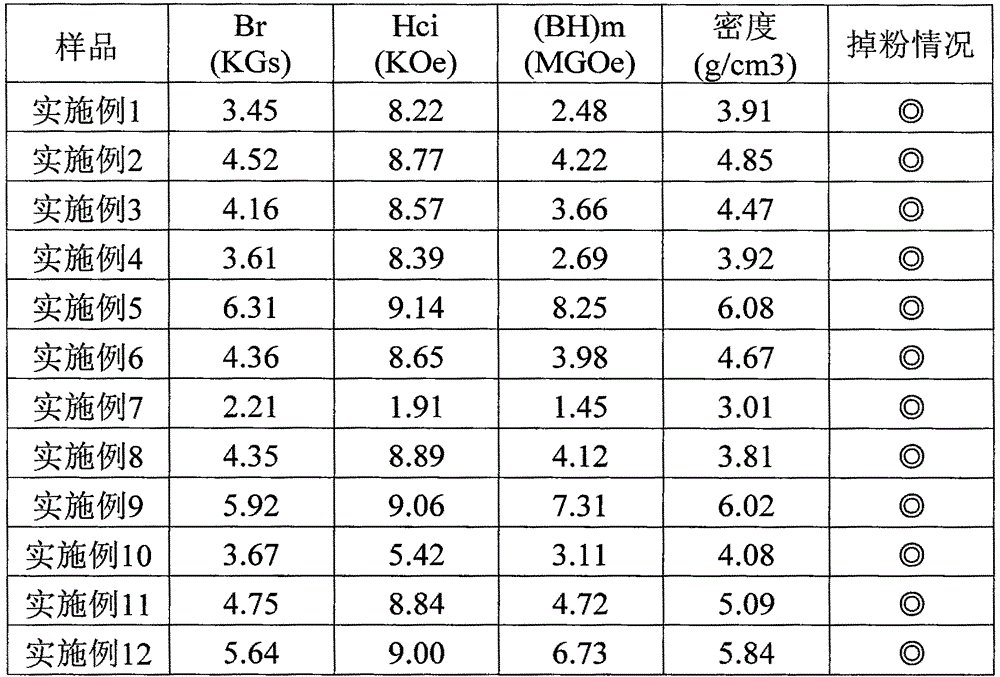

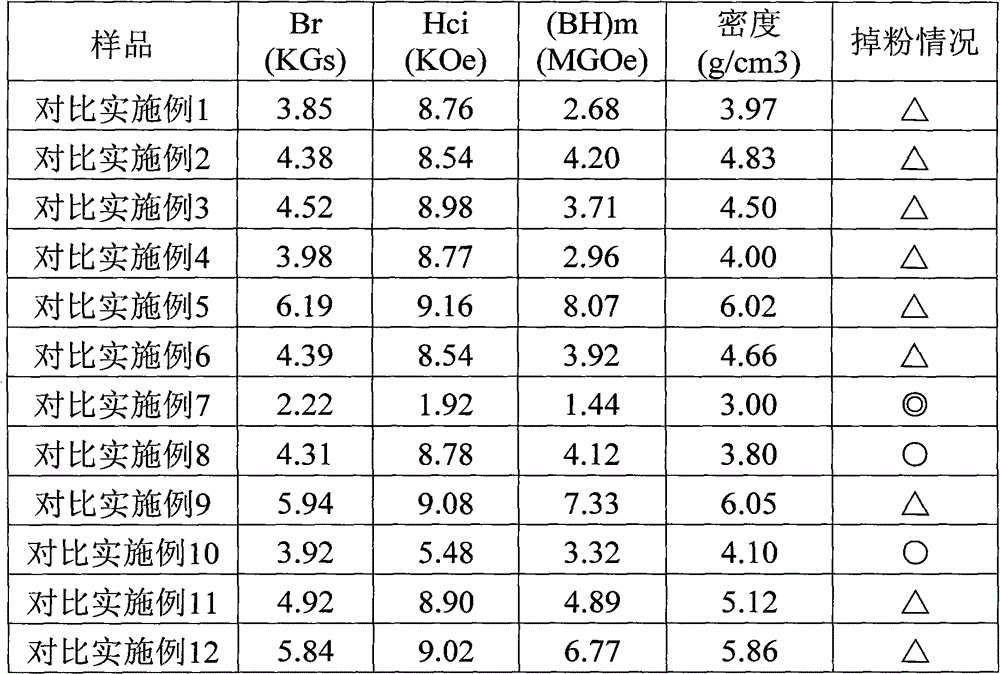

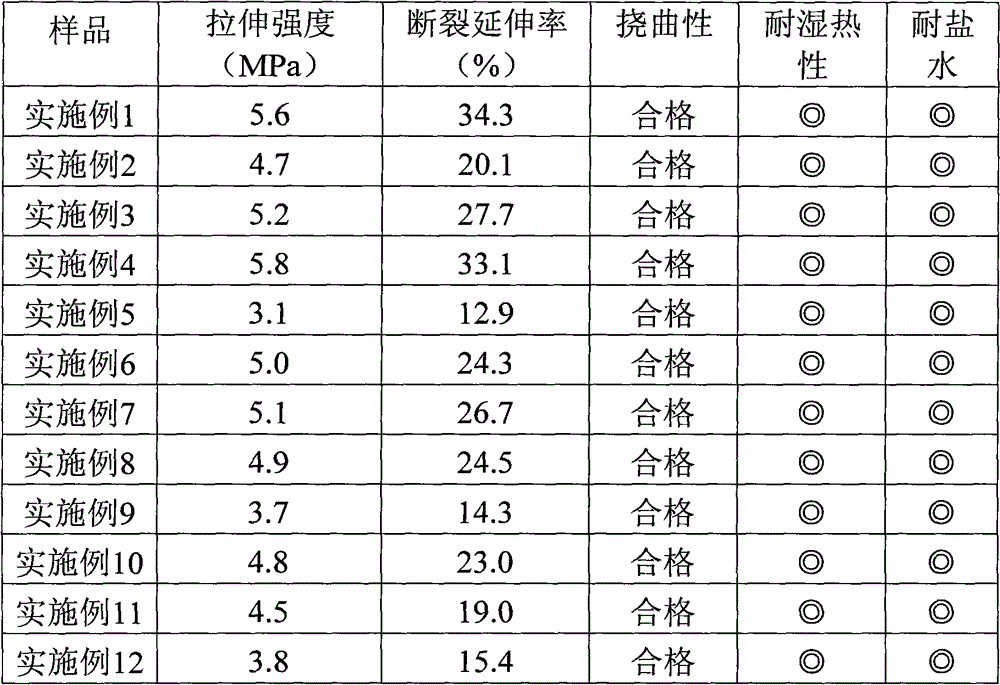

Examples

Embodiment 1

[0031] 1. Prepare the magnetic powder mixture according to the following formula and conduct experiments:

[0032] Flaky NdFeB magnetic powder (sheet diameter 45um, thickness-to-diameter ratio 1:16) 85wt%

[0033] Polyurethane 8.5wt%

[0034] Polyethylene 3.5wt%

[0035] Silicone oil 1.4wt%

[0036] Epoxidized soybean oil 1.3wt%

[0037] Silica powder (Fisher particle size 0.6um) 0.3wt%

[0038]The above-mentioned components are mixed evenly with a high-speed mixer (high-speed mixer GH-10DY type, Beijing Plastic Machinery Factory), and then mixed with an open mill (open mill XK-160, Wenzhou Eurasia Rubber and Plastic Machinery Co., Ltd.) The obtained mixture was mixed fully and evenly, and finally a magnetic sheet with a thickness of 1.5 mm was made with a calender (calender XY-2-230, Wuxi Wangda Rubber and Plastic Machinery Factory). 2. Determination of magnetic properties, tensile strength and elongation at break of magnetic sheets; flexibility test, salt water resistan...

Embodiment 2

[0045] 1. Prepare the magnetic powder mixture according to the following formula and conduct experiments:

[0046] Flake NdFeB magnetic powder (sheet diameter 60um, thickness-to-diameter ratio 1:35) 91wt%

[0047] Polyurethane 5.9wt%

[0049] Dioctyl phthalate 1.4wt%

[0050] Epoxidized soybean oil 1.0wt%

[0051] Calcium carbonate powder (Fisher particle size 0.1um) 0.1wt%

[0052] The above-mentioned components are mixed evenly with a high-speed mixer (high-speed mixer GH-10DY type, Beijing Plastic Machinery Factory), and then mixed with an open mill (open mill XK-160, Wenzhou Eurasia Rubber and Plastic Machinery Co., Ltd.) The obtained mixture was mixed fully and evenly, and finally a magnetic sheet with a thickness of 1.5 mm was made with a calender (calender XY-2-230, Wuxi Wangda Rubber and Plastic Machinery Factory).

[0053] 2. Determination of magnetic properties, tensile strength and elongation at break of magnetic sheets; flexibilit...

Embodiment 3

[0056] 1. Prepare the magnetic powder mixture according to the following formula and conduct experiments:

[0057] Flake NdFeN magnetic powder (sheet diameter 5um, thickness-to-diameter ratio 1:10) 88wt%

[0058] Nylon 69.0wt%

[0059] Wax liquid 0.4wt%

[0061] Epoxidized soybean oil 1.2wt%

[0062] Silicon nitride powder (Fisher particle size 0.1um) 0.1wt%

[0063] Silica powder (Fisher strength 1.0um) 0.3wt%

[0064] The above-mentioned components are mixed evenly with a high-speed mixer (high-speed mixer GH-10DY type, Beijing Plastic Machinery Factory), and then mixed with an open mill (open mill XK-160, Wenzhou Eurasia Rubber and Plastic Machinery Co., Ltd.) The obtained mixture was mixed fully and evenly, and finally a magnetic sheet with a thickness of 1.5 mm was made with a calender (calender XY-2-230, Wuxi Wangda Rubber and Plastic Machinery Factory).

[0065] 2. Determination of magnetic properties, tensile strength and elongation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com