Modified graphite, composite graphite material containing the modified graphite and their preparation methods and application

A composite graphite and graphite technology, applied in the directions of graphite, electrical components, battery electrodes, etc., can solve the problems of low compaction density of negative electrode materials, and achieve the effects of excellent comprehensive performance, good electrochemical performance and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

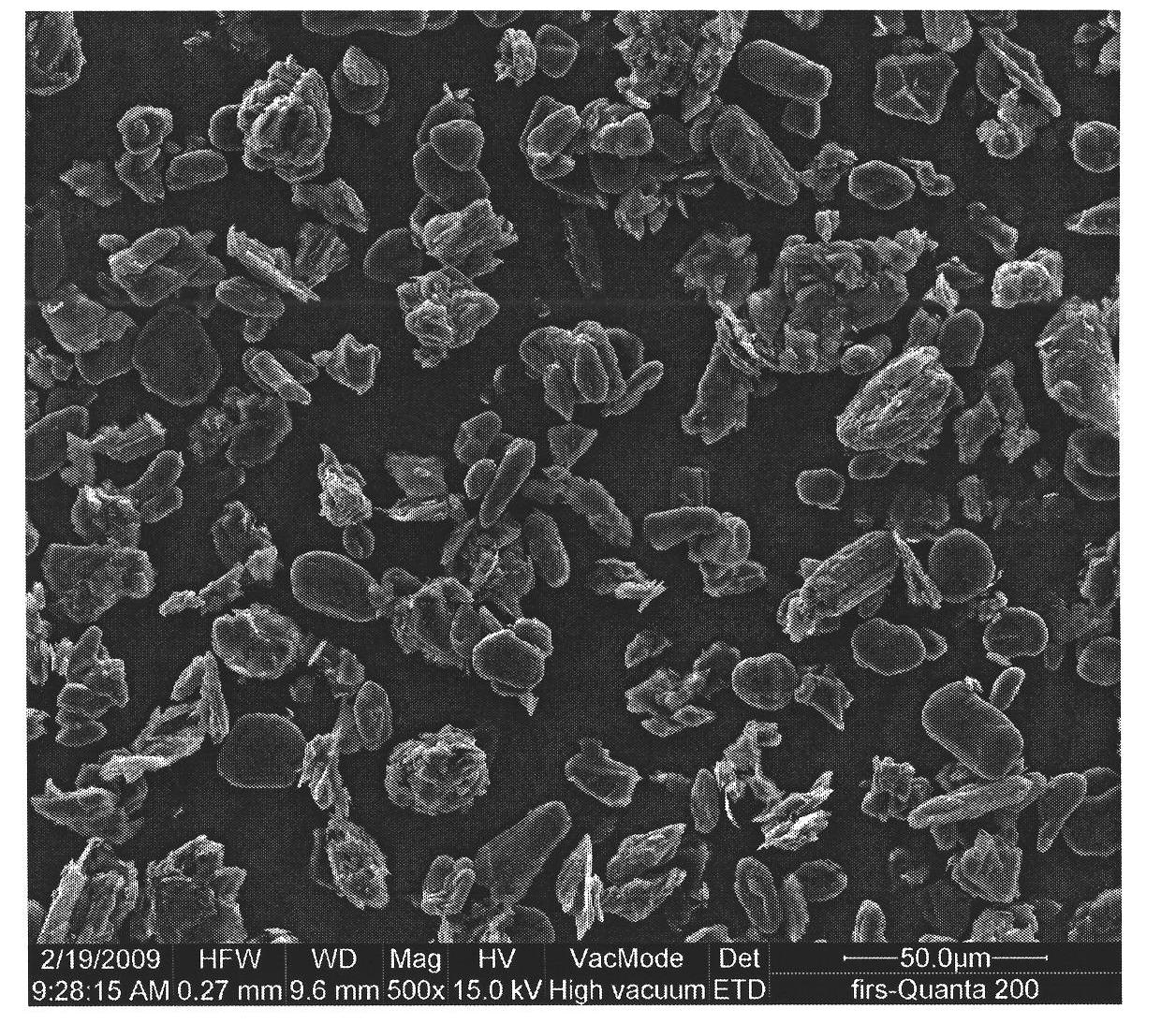

[0042] ①Crush the high-temperature petroleum asphalt to less than 0.1mm, and stir the spherical natural graphite (D 50 16.1 μm) 18kg and 2kg of the high-temperature petroleum asphalt powder are alternately added to the reactor and mixed, and then heat-coated;

[0043] ② After coating, under the protection of nitrogen, carry out surface carbonization treatment at a constant temperature of 1100°C for 2 hours, and cool to room temperature to obtain surface-modified spherical graphite;

[0044] ③Spherical graphite 12kg treated with surface modification and graphitization catalyst Fe 2 o 3 1kg is alternately added to the cantilever double-helix conical mixer and mixed;

[0045] ④Carry out high-temperature catalytic graphitization treatment at 2800°C for 48 hours to obtain modified graphite;

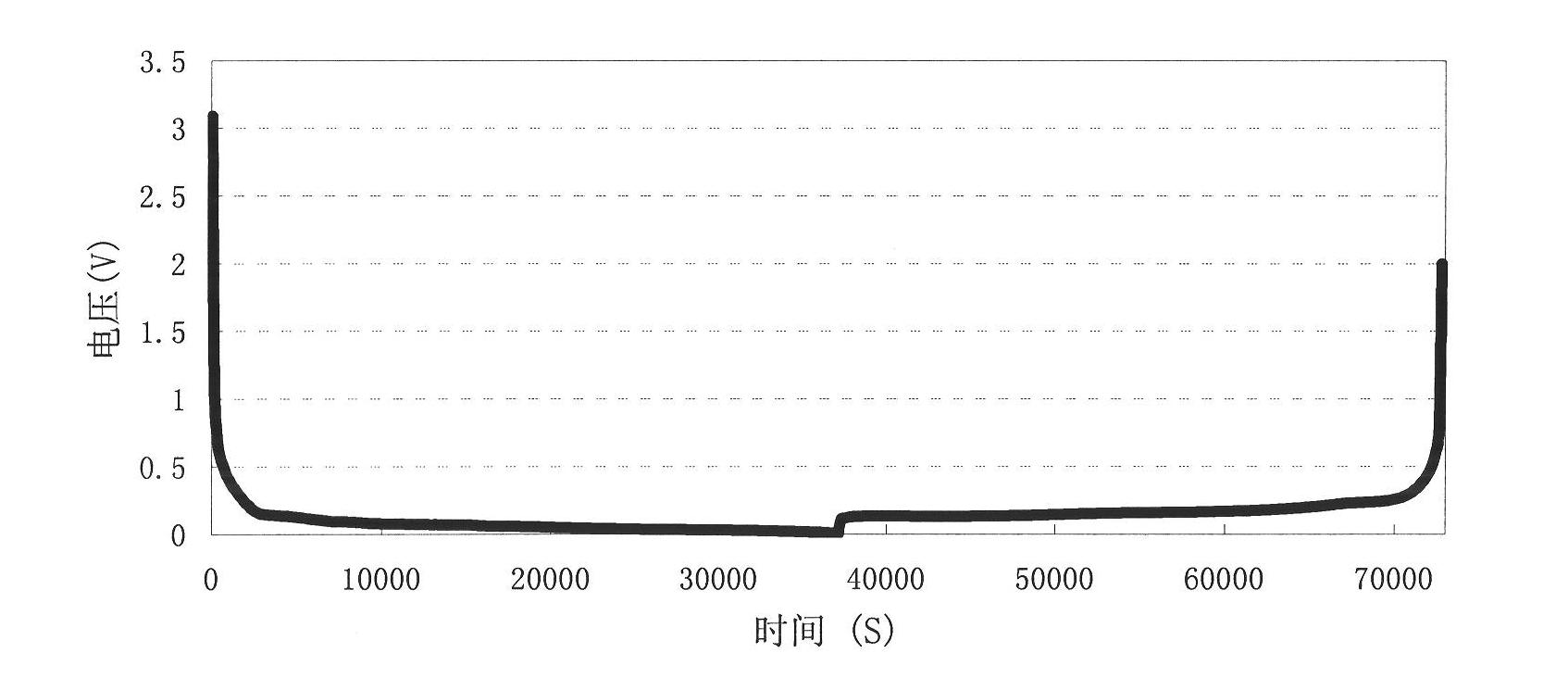

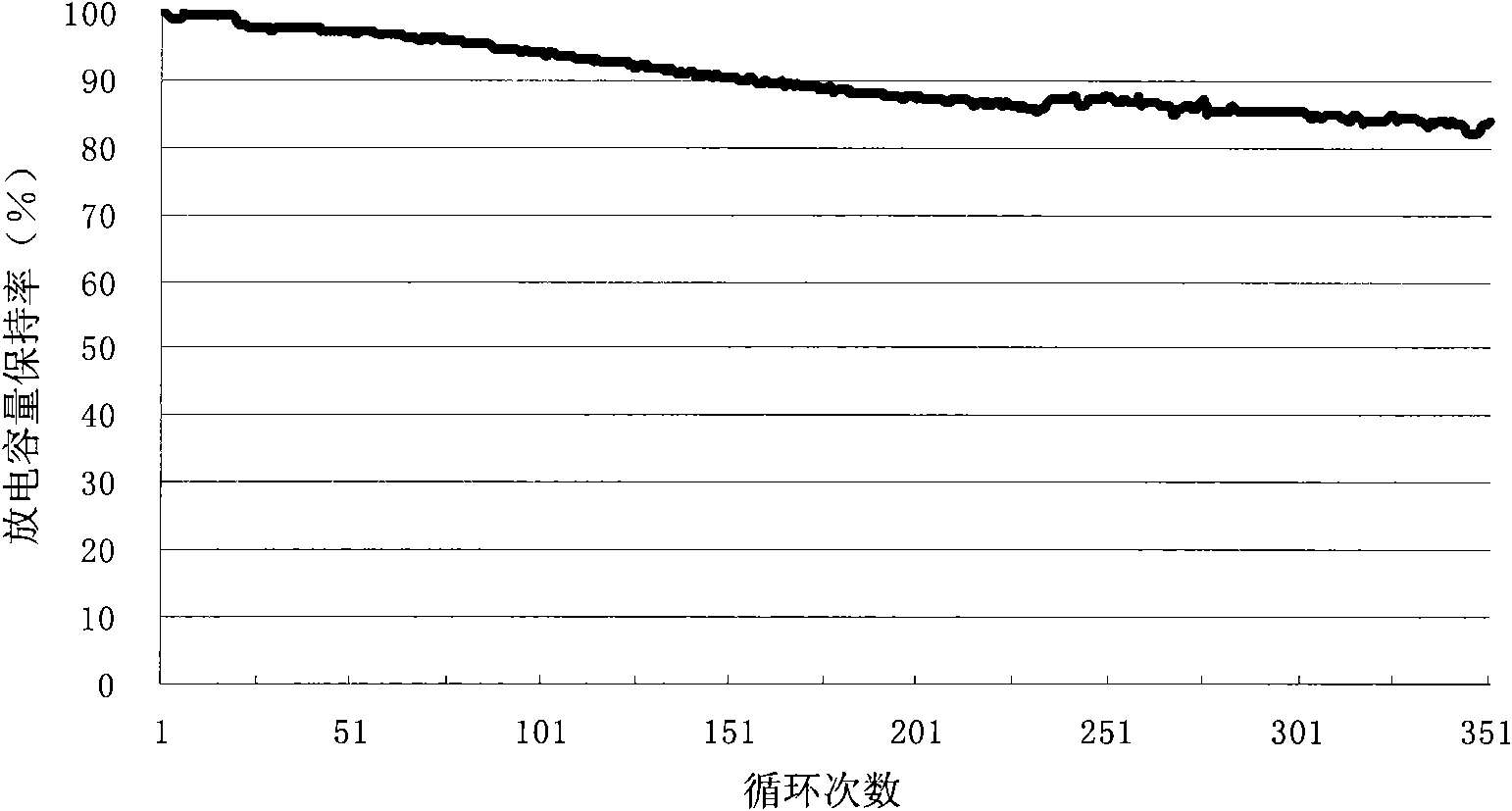

[0046] 5. Mix the modified graphite and the artificial graphite uniformly at a mass ratio of 80:20 to obtain a composite graphite material, the first discharge capacity of the half-cell is ...

Embodiment 2

[0048] ①Crush the high-temperature petroleum asphalt to less than 0.1mm, and stir the spherical natural graphite (D 50 16.5 μm) 18kg and 2kg of the high-temperature petroleum asphalt powder are alternately added to the reactor and mixed for heat coating treatment;

[0049] ② After coating, under the protection of nitrogen, carry out surface carbonization treatment at a constant temperature of 800°C for 6 hours, and cool to room temperature to obtain surface-modified spherical graphite;

[0050] 3. the spherical graphite 20kg of described surface modification process and graphitization catalyst SiO 2 2kg is alternately added to the cantilever double-helix conical mixer and mixed;

[0051] ④Carry out catalytic graphitization high temperature treatment at 3000°C for 50 hours to obtain modified graphite;

[0052] 5. Mix the modified graphite and the artificial graphite uniformly at a mass ratio of 90:10 to obtain a composite graphite material, the first discharge capacity of th...

Embodiment 3

[0054] ①Crush the modified coal tar pitch to less than 0.1mm, and stir the spherical natural graphite (D 50 16.1 μm) 18kg and 2kg of the modified coal tar pitch powder are alternately added to the reactor and mixed, and then heat-coated;

[0055] ② After coating, under the protection of nitrogen, carry out surface carbonization treatment at a constant temperature of 1500°C for 3 hours, and cool to room temperature to obtain surface-modified spherical graphite;

[0056] 3. The spherical graphite 28.5kg of described surface modification process and graphitization catalyst B 2 o 3 1.5kg is alternately added to the cantilever double-helix conical mixer and mixed;

[0057] ④Carry out high-temperature catalytic graphitization treatment at 3200°C for 30 hours to obtain modified graphite;

[0058] 5. Mix the modified graphite and the artificial graphite uniformly at a mass ratio of 50:50 to obtain a composite graphite material, the first discharge capacity of the half-cell is 365.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com