Adsorbent for removing PFOS and PFOA in water and preparation method thereof

An adsorbent and water removal technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of complex preparation process, narrow applicable pH range, low adsorption capacity, etc., and achieve good adsorption effect , low price, easy to degrade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

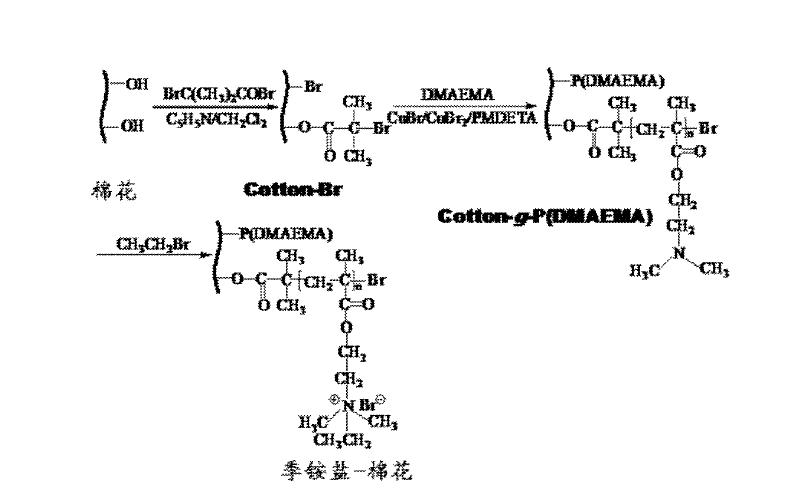

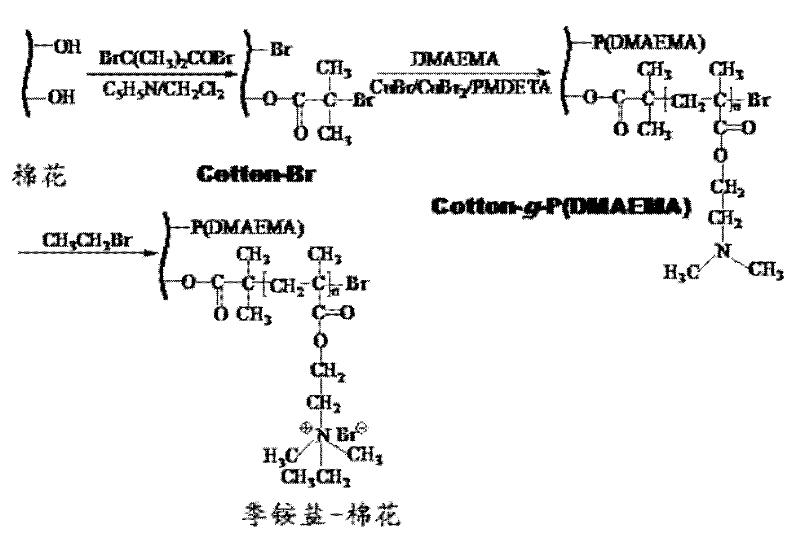

[0021] (a) Preparation of ATRP initiator: Mix cotton with dichloromethane, α-bromoisobutyryl bromide, and pyridine, react at room temperature for 24 hours, then wash with dichloromethane, acetone or tetrahydrofuran, and high-purity water successively, and dry Finally, the ATRP initiator cotton-Br was obtained. The dosage ratio of each substance is: 0.3g cotton: 15mL dichloromethane: 3mL a-bromoisobutyryl bromide: 1mL pyridine.

[0022] (b) ATRP reaction: the ATRP initiator cotton-Br in the presence of water, methanol, N, N, N', N', N "-pentamethyldiethylenetriamine, cuprous bromide, copper bromide Utilize ATRP reaction to initiate DMAEMA monomer polymerization, obtain the cotton that contains PDMAEMA polymer brush after washing and drying with acetone or tetrahydrofuran (THF) and high-purity water, i.e. cotton-g-P (DMAEMA).Described each material consumption ratio is listed as: 0.05g cotton- Br: 1mL H 2 O: 2mL methanol: 3mL DMAEMA: 45 μL N, N, N', N', N"-pentamethyldiethylen...

Embodiment 1

[0030] The preparation steps of the adsorbent in this embodiment are:

[0031](1) Take 0.3g of raw cotton and put it into a test tube, then add dichloromethane (15mL), a-bromoisobutyryl bromide (3mL) and pyridine (1mL) in sequence, mix well and seal it with a rubber stopper. The tube was placed in a shaker with a temperature of 25°C and a rotational speed of 150 rpm, and was taken out after 24 hours of reaction, and washed with dichloromethane, acetone, and high-purity water in sequence, so that the ATRP initiator was introduced on the cotton surface, and the tube was prepared. get cotton-Br;

[0032] (2) Get 0.05g of the above ATRP initiator cotton-Br and put it into a round bottom flask, then add H 2 O (1mL), methanol (2mL), DMAEMA (3mL) and N, N, N', N', N"-pentamethyldiethylenetriamine (45 μL), then feed nitrogen into the reaction flask, so that Remove the oxygen in the bottle, and add 18 mg of cuprous bromide and 3.6 mg of copper bromide under the condition of nitrogen ...

Embodiment 2

[0036] The preparation steps of the adsorbent in this embodiment are:

[0037] (1) Take 0.3g of raw cotton and put it into a test tube, then add dichloromethane (15mL), a-bromoisobutyryl bromide (3mL) and pyridine (1mL) in sequence, mix well and seal with a rubber stopper. The tube was placed in a shaker with a temperature of 25°C and a rotational speed of 150 rpm, and was taken out after 24 hours of reaction, and washed with dichloromethane, acetone, and high-purity water in sequence, so that the ATRP initiator was introduced on the cotton surface, and the tube was prepared. get cotton-Br;

[0038] (2) Get 0.05g of the above ATRP initiator cotton-Br and put it into a round bottom flask, then add H 2 O (1mL), methyl alcohol (2mL), DMAEMA (3mL), cuprous bromide (18mg), cupric bromide (3.6mg), feed nitrogen into reaction bottle then, can remove the oxygen in bottle like this, and in 45 μL of N, N, N′, N′, N″-pentamethyldiethylenetriamine under nitrogen gas. After 15 minutes of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com