Method for preparing and purifying tiopronin disulphide

A technology of tiopronin disulfide and tiopronin, which is applied in the field of preparation and purification of tiopronin disulfide reference substance, can solve problems such as difficult preparation and purification of tiopronin disulfide, and achieve reduction of organic solvent residues , easy to remove, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

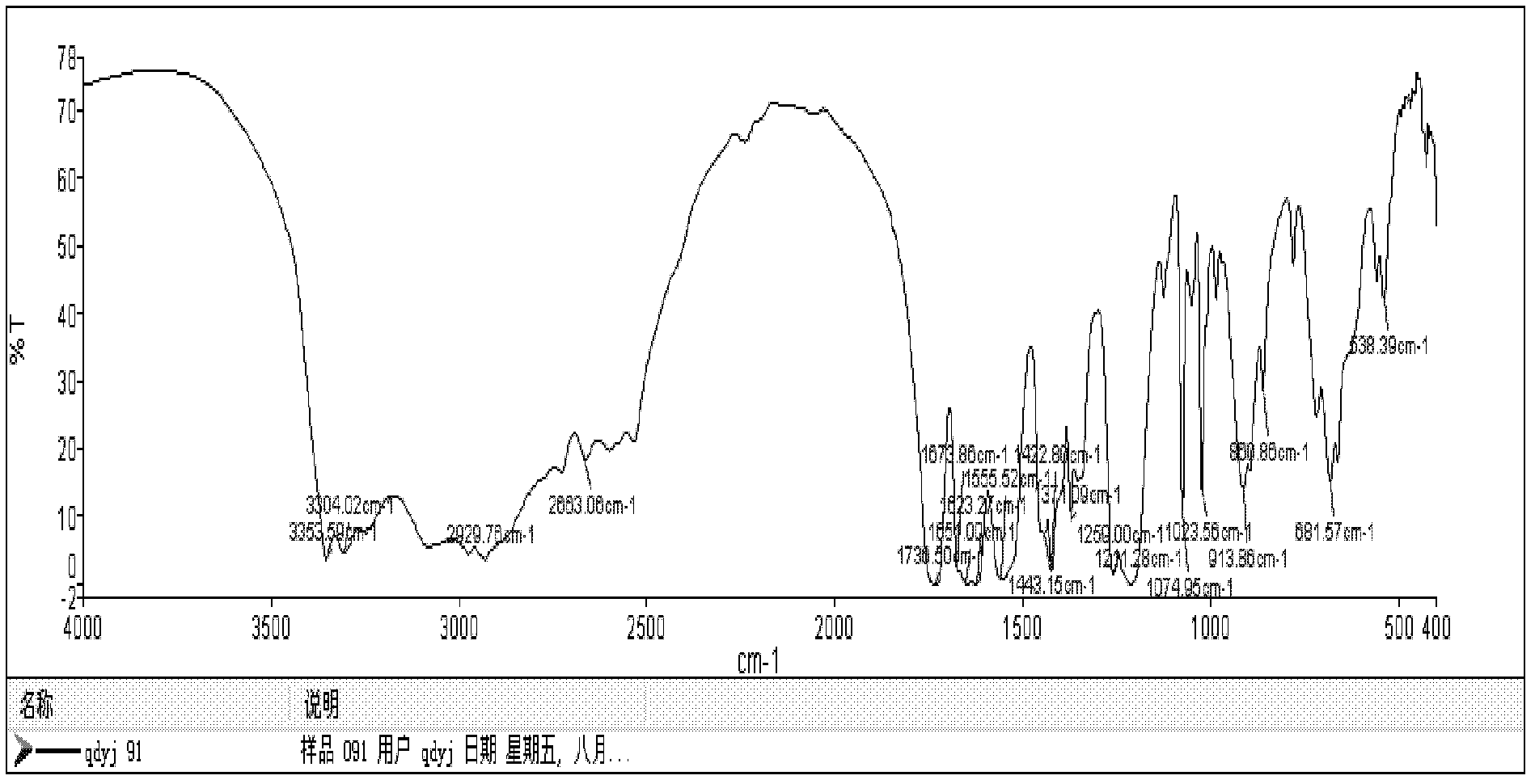

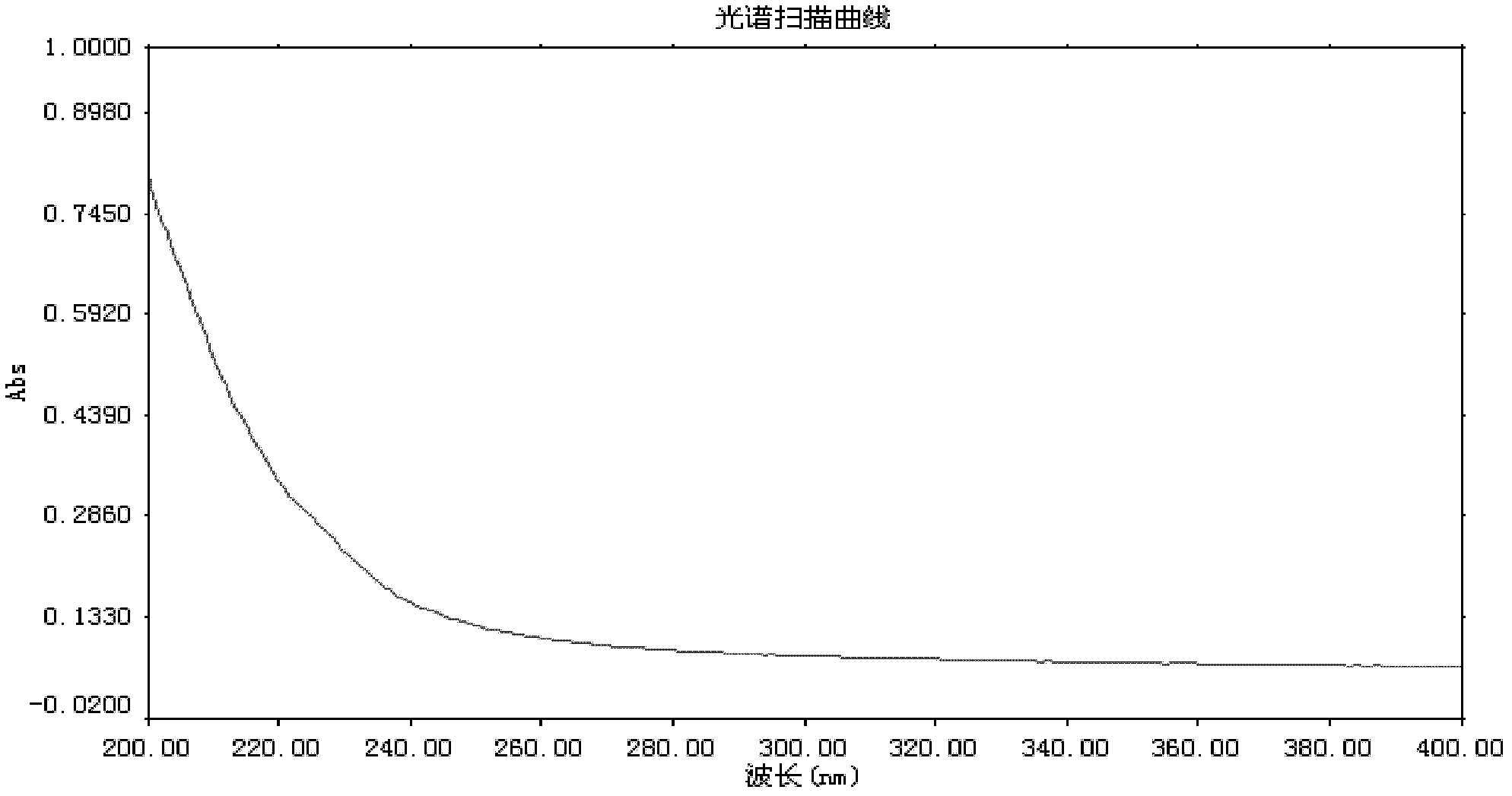

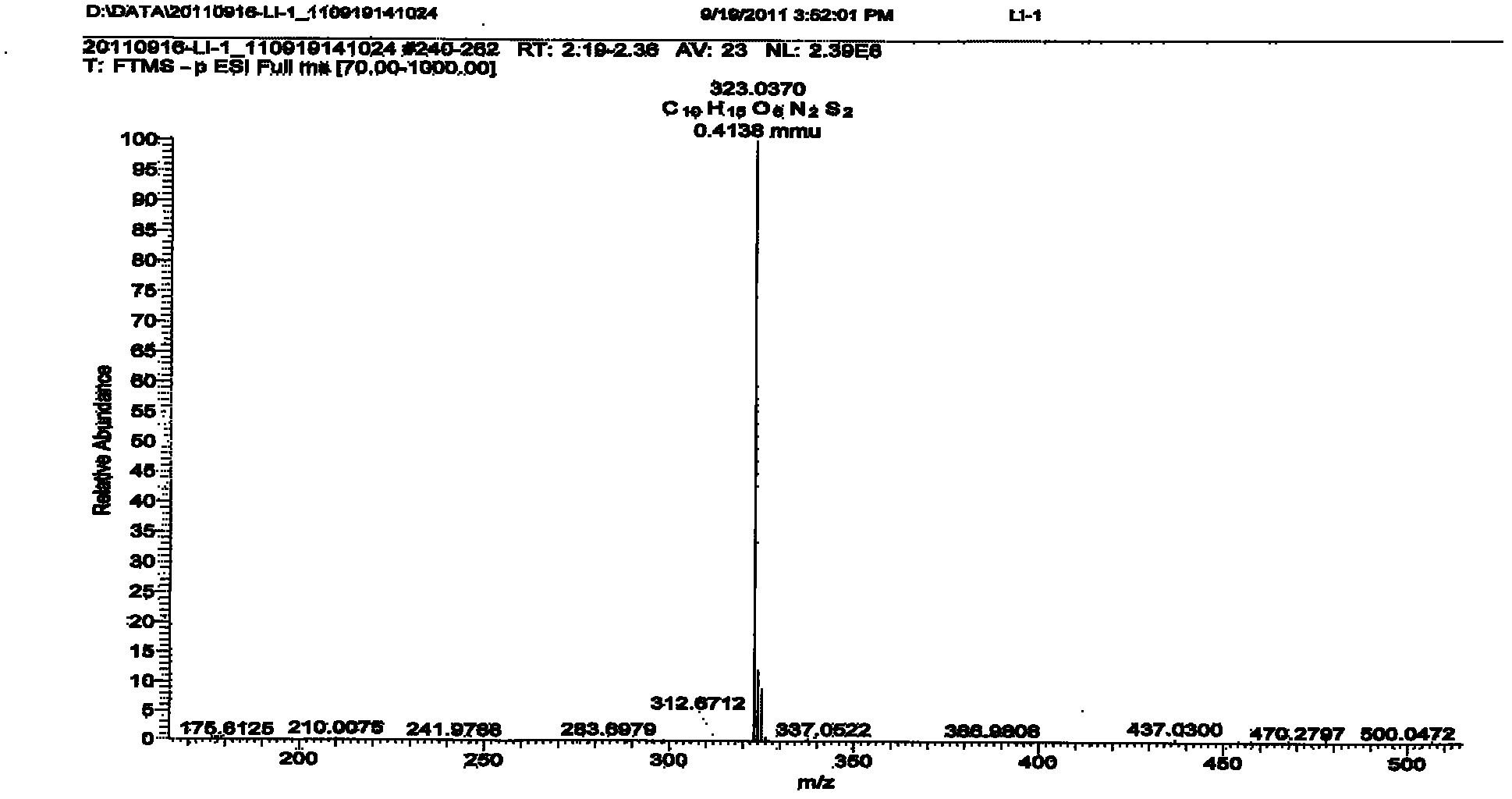

Image

Examples

Embodiment 1

[0020] 1) Oxidize Thiopronin to obtain Tiopronin Disulfide:

[0021] Tiopronin 5g is dissolved in 100ml of water, 50ml of aqueous hydrogen peroxide solution with a volume concentration of 10% is added dropwise, and the reaction is continuously stirred for 24 hours. % of tiopronin disulfide.

[0022] 2) Preparative HPLC purification:

[0023] The light yellow viscous solution was dissolved with 50ml of 0.1% formic acid aqueous solution containing acetonitrile volume concentration ratio of 10% to prepare the test solution, and filtered through a 0.45 μm microporous membrane; the packing material brand of the prepared chromatographic column was Chromatorex C18 bonded phase Packing, prepared column length 10cm, diameter 7.5cm; mobile phase with 0.1% formic acid aqueous solution containing 10% acetonitrile volume concentration ratio; injection volume is 10ml, flow rate is controlled at 160ml / min; detection wavelength is 210nm; collection retention time It is the fraction of 13.5-...

Embodiment 2

[0029] 1) Oxidize Thiopronin to obtain Tiopronin Disulfide:

[0030] Tiopronin 10g is dissolved in 100ml of water, 100ml of aqueous hydrogen peroxide solution with a volume concentration of 20% is added dropwise, and the reaction is continuously stirred for 48 hours. % of tiopronin disulfide.

[0031] 2) Preparative HPLC purification:

[0032] Add 100 ml of 0.1% formic acid aqueous solution containing acetonitrile volume concentration ratio of 7% to the light yellow viscous solution to dissolve to prepare the test solution, and filter it through a 0.45 μm microporous membrane; the packing material brand of the prepared chromatographic column is Microsorb C18 bonded phase Packing, preparation column length 15cm, diameter 5cm; With the 0.1% formic acid aqueous solution that contains acetonitrile volume concentration ratio of 7% as mobile phase; Injection volume is 10ml, and flow rate is controlled at 180ml / min; Detection wavelength is 210nm; Collection retention time is 14.5-1...

Embodiment 3

[0036] 1) Oxidize Thiopronin to obtain Tiopronin Disulfide:

[0037] Tiopronin 10g is dissolved in 100ml of water, 100ml of aqueous hydrogen peroxide solution with a volume concentration of 30% is added dropwise, and the reaction is continuously stirred for 72 hours. % crude product of tiopronin disulfide.

[0038] 2) Preparative HPLC purification:

[0039] The light yellow viscous solution was dissolved in 120ml of 0.1% formic acid aqueous solution containing 5% of acetonitrile volume concentration to prepare the test solution, and filtered through a 0.45 μm microporous membrane; the packing material brand of the prepared chromatographic column was Chromatorex C18 bonded phase Packing, preparation column length 20cm, diameter 7.5cm; 0.1% formic acid aqueous solution containing acetonitrile volume concentration ratio of 5% as the eluting system; injection volume is 40ml, flow rate is controlled at 140ml / min; detection wavelength is 210nm; collection and retention Fractions w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com