Preparation method of order meso porous manganese dioxide/ conductive polyaniline composite material

A technology for conducting polyaniline and manganese dioxide is applied in the field of preparation of ordered mesoporous manganese dioxide/conducting polyaniline composite materials, which can solve the problems of small specific surface area and low electrical conductivity, and can improve specific capacity and performance. , the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

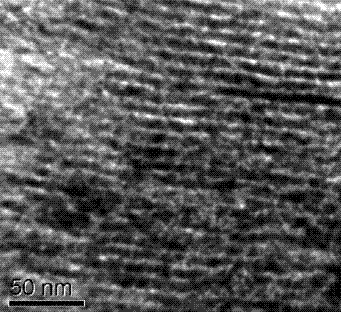

[0030] Embodiment 1: a kind of preparation method of highly ordered mesoporous manganese dioxide / conductive polyaniline composite material, comprises the following steps:

[0031] (1) According to the ratio of template agent, catalyst and distilled water in mass parts ratio of 1︰0.24~4︰26~40 and the ratio of template agent, silicon source and manganese source in mass part ratio of 1︰0.5~1.2︰1.0 ~2.0 ratio, mix 4.0g triblock copolymer P123, 160g distilled water, 16g concentrated hydrochloric acid, stir in 50°C water bath for 6 hours (hours) until all surfactants are dissolved and the solution is clear; add 4.8g ethyl orthosilicate ester, stirred for 20 hours, added 8g of manganese nitrate and continued to stir for 48 hours; transferred the reacted solid-liquid mixture to a 300ml high-pressure reaction tank, hydrothermally crystallized at 150°C for 6h, filtered and washed; dried at 120°C for 4h, and calcined at 500°C for 8h to obtain ordered mesoporous manganese dioxide;

[003...

Embodiment 2

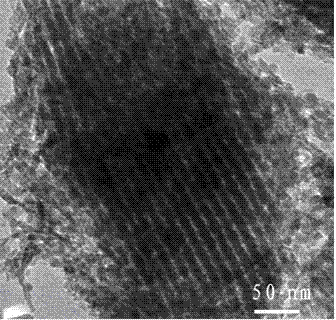

[0035]Example 2: Use this method to prepare highly ordered mesoporous manganese dioxide / conductive polyaniline composite materials, the steps are the same as in Example 1, 6.0g of triblock copolymer F127 is dissolved in 156g of distilled water, and 1.44g of concentrated sulfuric acid is added Stir in a water bath at 20°C for 1 hour until all the surfactants are dissolved; immediately after stirring for 1 hour, add 3.0g of sodium silicate and stir for 20 hours; add 6.0g of manganese chloride and continue stirring for 20 hours; transfer the reacted solid-liquid mixture to a 300ml high-pressure reaction tank 100°C for hydrothermal crystallization for 2 hours, filtered and washed; dried at 100°C for 4 hours, and calcined at 400°C for 4 hours to obtain ordered mesoporous manganese dioxide; add 25 times the amount of sodium hydroxide according to the amount matched to obtain an ordered mesoporous mixture Solution, 0.5mol / L, soaked at 50°C for 24h to remove the silicon template, filte...

Embodiment 3

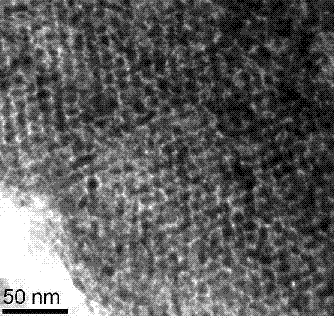

[0037] Embodiment 3: use this method to prepare highly ordered mesoporous manganese dioxide / conductive polyaniline composite material, step is the same as embodiment 1, with 5.0g cetyltrimethylammonium bromide (CTAB), be dissolved in 200 g distilled water, add 10g NaOH and stir in a water bath at 35°C for 4 h until all the surfactants are dissolved; immediately add 4.0 g methyl orthosilicate and stir for 20 h; then adjust the pH value to 9-10 with 0.3 mol / L HCl solution, Add 10g of manganese acetate and continue stirring for 40h, transfer the reacted solid-liquid mixture to a 300ml high-pressure reaction tank, hydrothermally crystallize at 150°C for 6h, filter and wash; dry at 100°C for 4h, and calcinate at 450°C for 7h to obtain ordered mesoporous Manganese oxide: add 20 times the amount of sodium hydroxide solution according to the matching amount of the ordered mesoporous mixture, 1mol / L, soak at 50°C for 20h to remove the silicon template, filter, wash until neutral, and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com