In-situ preparation method for photoanode of silicon-tungsten and TiO2 codoped nanotube film

An in-situ preparation and nanotube technology, applied in photovoltaic power generation, photosensitive equipment, capacitor electrodes, etc., can solve problems such as complex processes, and achieve high energy conversion efficiency and good visible light activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

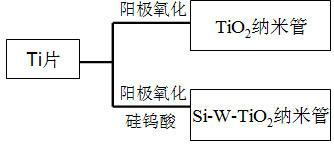

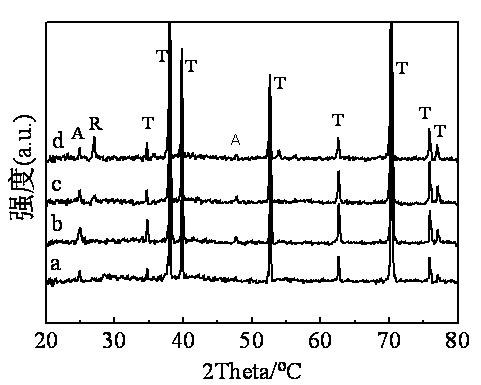

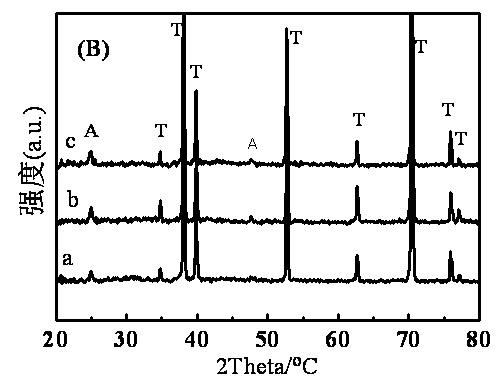

[0026] Example 1: Dilute the Ti sheet with V(deionized water):V(HNO 3 ):V(HF)=5:4:1 solution for pretreatment, and then clean the Ti sheet with deionized water and dry it under air flow. The pretreated Ti sheet was used as the anode, the graphite sheet was used as the cathode, 0.2 M silicotungstic acid was added to the 0.5% HF solution as the electrolyte, the voltage of 20 V was controlled by a DC regulated power supply, anodized for 40 min under magnetic stirring, and finally Repeatedly rinsed with deionized water and dried with air flow to obtain silicon-tungsten co-doped TiO 2 nanotube films (see figure 2 B SEM image). Put the anodized Ti sheet in a porcelain boat, then put it in a muffle furnace, and raise the temperature to 450 o C, the heat treatment time is 2.5 hours. The heat-treated Ti sheets were ultrasonically cleaned with deionized water, and dried under air flow for later use.

[0027] The pretreated Ti sheet was used as the anode, the graphite sheet was u...

Embodiment 2

[0031] Example 2: The pretreatment process of metal titanium sheet is the same as embodiment 1. The pretreated Ti sheet was used as the anode, and the graphite sheet was used as the cathode, and 0.04 M silicotungstic acid was added to the 0.5% HF solution as the electrolyte, and the voltage of 20 V was controlled by a DC stabilized power supply, anodized for 40 min under magnetic stirring, and finally Rinse with deionized water repeatedly, and dry with air flow to obtain TiO 2 nanotube film. The post-processing process and the photoelectric current testing process are the same as in Example 1. Figure 10 showing Si and W co-doped TiO 2 The photocurrent value of the nanotube film electrode under visible light is 0.51 μA / cm 2 .

Embodiment 3

[0032] Example 3: The pretreatment process of metal titanium sheet is the same as embodiment 1. Dilute the Ti sheet with V(deionized water):V(HNO 3 ):V(HF)=5:4:1 solution for pretreatment, and then clean the Ti sheet with deionized water and dry it under air flow. The pretreated Ti sheet was used as the anode, the graphite sheet was used as the cathode, 0.4 M silicotungstic acid was added to the 0.5% HF solution as the electrolyte, and the voltage of 20 V was controlled by a DC stabilized power supply, and anodized for 40 min under magnetic stirring. Rinse with deionized water repeatedly, and dry with air flow to obtain TiO 2 nanotube film. The post-processing process and the photoelectric current testing process are the same as in Example 1. The XPS analysis of the surface composition of the doped sample can confirm the existence of Si element and W element in the sample, the atomic ratio of Si / Ti is 0.10, and the atomic ratio of W / Ti is 0.09. Figure 10 Show Si-W-TiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com