Method for directly preparing tetrafluoromethane from fluorocarbon using explosion suppressant

A technology of tetrafluoromethane and detonation inhibitor, which is applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problems of high cost, high generation risk, difficulty in tetrafluoromethane, etc., and achieves low production cost. , stable quality, good use of cold and heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

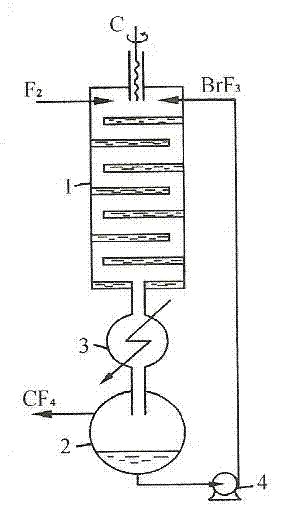

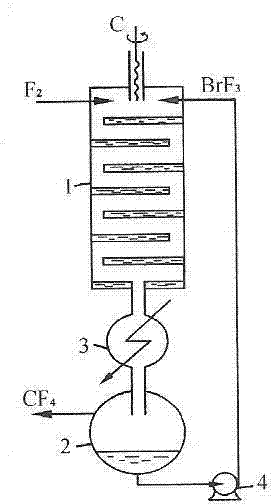

[0026] (1) Under the condition of integrated continuous feeding, in BrF 3 Under the condition of making explosion suppressant, use 60 mesh petroleum coke and F 2 The process of preparing high-purity tetrafluoromethane by reaction; wherein the volume ratio of antiknock agent to fluorine gas is 1:20; the amount of petroleum coke added is 500 kg / time, F 2 The amount added is 10 liters / minute;

[0027] (2) The fluorinated halogen is drawn out from the receiver 2 by the pump 4 and sent to the top of the reactor 1, carbon particles are added from the top of the reactor, and pure F is introduced from the other side of the top 2 ; Keep the system reacting at 127°C, at this time BrF 3 start to vaporize;

[0028] (3) The generated mixed gas and BrF3 liquid flow downward, and after being cooled to 30°C by the condenser 3, the liquid BrF3 3 Enter the loop in the receiver;

[0029] (4) Crude tetrafluoromethane gas is derived from the receiver above, and...

Embodiment 2

[0031] (1) Under the condition of integrated continuous feeding, use bromine trifluoride as explosion suppressant, use 60 mesh petroleum coke and F 2 reaction to prepare high-purity tetrafluoromethane; wherein the volume ratio of antiknock agent to fluorine gas is 1:20; petroleum coke addition is 550 kg / time, F 2 The amount added is 12 liters / minute;

[0032] (2) The fluorinated halogen is drawn out from the receiver 2 by the pump 4 and sent to the top of the reactor 1, carbon particles are added from the top of the reactor, and pure F is introduced from the other side of the top 2 ; Keep the system reacting at 127°C, at this time BrF 3 start to vaporize;

[0033] (3) The generated mixed gas and BrF3 liquid flow downward, and after being cooled to 30°C by the condenser 3, the liquid BrF3 3 Enter the loop in the receiver;

[0034] (4) Crude tetrafluoromethane gas is derived from the receiver above, and the entrained fluorinated halogen is recover...

Embodiment 3

[0036] (1) Under the condition of integrated continuous feeding, use bromine trifluoride as explosion suppressant, use 60 mesh petroleum coke and F 2 reaction to prepare high-purity tetrafluoromethane; wherein the volume ratio of antiknock agent to fluorine gas is 1:12; the amount of petroleum coke added is 500 kg / time, F 2 The amount added is 11 liters / minute;

[0037] (2) The fluorinated halogen is drawn out from the receiver 2 by the pump 4 and sent to the top of the reactor 1, carbon particles are added from the top of the reactor, and pure F is introduced from the other side of the top 2 ; Keep the system reacting at 127°C, at this time BrF 3 start to vaporize;

[0038] (3) The resulting mixed gas and BrF 3 The liquid flows downward, and after being cooled to 30°C by the condenser 3, the liquid BrF 3 Enter the loop in the receiver;

[0039] (4) Crude tetrafluoromethane gas is derived from the receiver above, and the entrained fluorinat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com