Preparation method of modified cross-linked bisphenol A reinforcement adhesive for ballastless track mortar defect repair

A ballastless track and adhesive technology, applied in the direction of adhesives, adhesive additives, epoxy resin glue, etc., can solve the problems that cannot meet the construction requirements, poor fluidity, small shrinkage and bond strength, etc., and achieve the edge sealing process Strong operability, reduced economic loss, and good anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

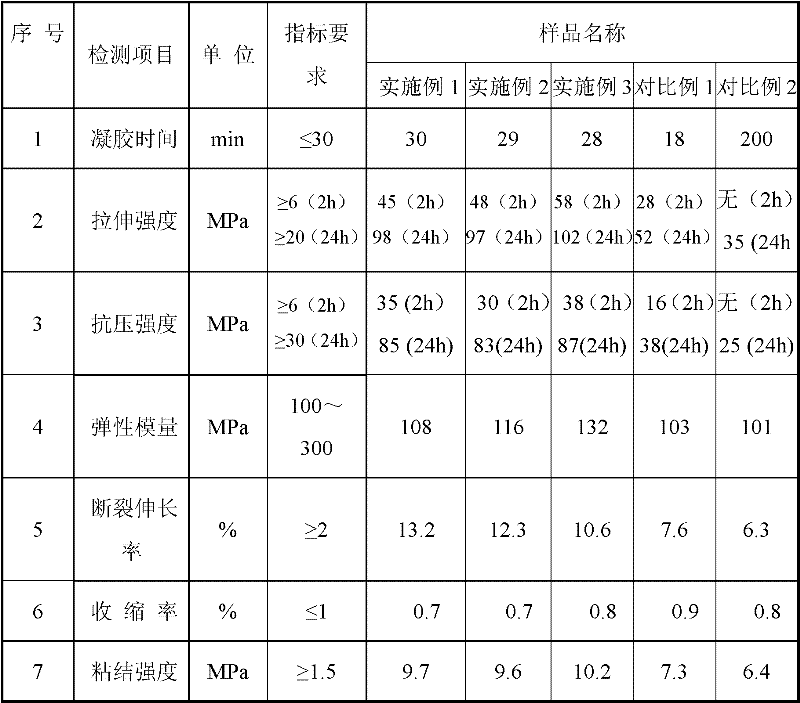

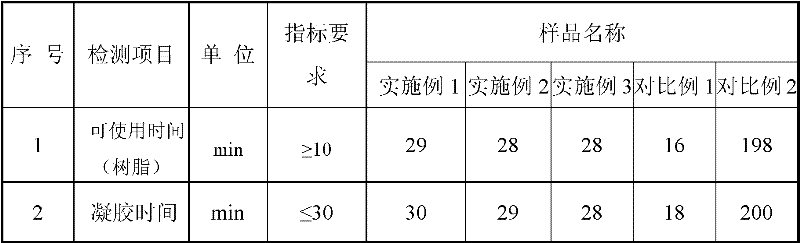

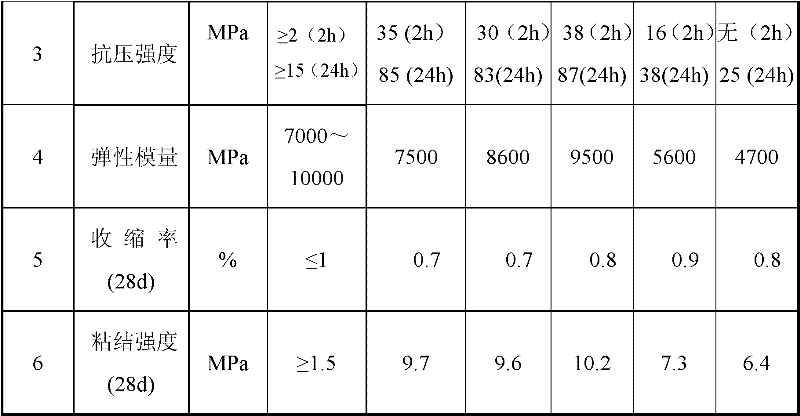

Examples

Embodiment 1

[0019] Example 1: A method for preparing a modified cross-linked bisphenol A reinforcing adhesive for repairing defects in ballastless track mortar, including:

[0020] (1) Preparation of bisphenol A epoxy resin main agent: Add 100 parts of bisphenol A and 20 parts of 1,6-hexanediol diglycidyl ether into the reaction vessel, stir and dissolve at 40°C for 2.0h, and wait for stirring After completion, add 20 parts of heavy calcium carbonate to prepare a viscosity of 8000mPa·S bisphenol A epoxy resin main agent;

[0021] (2) Synthesis of polythiol-polyamide composite modified curing agent: 25 parts of 2-2'-dimercaptoethyl sulfide, 25 parts of trimethylolpropane triacrylate and 0.2 part of triethylamine Place in a reaction vessel, pass through nitrogen protection, stir and react at 70°C for 8 hours to obtain a colorless and transparent polythiol modifier with a multi-branched structure, then add 250 parts of polyamide curing agent, and stir evenly

[0022] .After 1.5h of heat pre...

Embodiment 2

[0024] Example 2: A method for preparing a modified cross-linked bisphenol A reinforcing adhesive for repairing defects in ballastless track mortar, including:

[0025] (1) Preparation of bisphenol A epoxy resin main agent: Add 100 parts of bisphenol A and 20 parts of 1,4-butanediol diglycidyl ether into the reaction vessel, stir and dissolve at 40°C for 2.0 hours, and wait until the stirring is completed After adding 20 parts of aluminum hydroxide, the prepared viscosity is 8200mPa·S bisphenol A epoxy resin main agent;

[0026] (2) Synthesis of polythiol-polyamide composite modified curing agent: 20 parts of 2-2'-dimercaptoethyl sulfide, 20 parts of trimethylolpropane triacrylate and 0.2 part of triethylamine Place in a reaction vessel, pass through nitrogen protection, stir and react at 70°C for 8 hours to obtain a colorless and transparent polythiol modifier with a multi-branched structure, then add 200 parts of polyamide curing agent, and stir evenly

[0027] .After 1.5 h...

Embodiment 3

[0029] Example 3: A method for preparing a modified cross-linked bisphenol A reinforcing adhesive for repairing defects in ballastless track mortar, including:

[0030] (1) Preparation of bisphenol A epoxy resin main agent: Add 100 parts of bisphenol A and 20 parts of 1,4-butanediol diglycidyl ether into the reaction vessel, stir and dissolve at 40°C for 2.0 hours, and wait until the stirring is completed Then add 20 parts of heavy calcium carbonate and 10 parts of gas phase SiO 2 , to prepare a viscosity of 9000mPa·S bisphenol A epoxy resin main agent;

[0031] (2) Synthesis of polythiol-polyamide composite modified curing agent: 20 parts of 2-2'-dimercaptoethyl sulfide, 20 parts of trimethylolpropane triacrylate and 0.2 part of triethylamine Place in a reaction vessel, pass through nitrogen protection, stir and react at 70°C for 8 hours to obtain a colorless and transparent polythiol modifier with a multi-branched structure, then add 200 parts of polyamide curing agent, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com