Preparation method for alkaline earth fluo-chloride up-conversion luminescence nanometer crystal

A technology of fluoride chloride and nanocrystals, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems that have not been seen to successfully prepare monodisperse alkaline earth fluoride chloride nanocrystals, and achieve uniform shape, high yield, and preparation technically simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] Example 1: 0.5mmol strontium trifluoroacetate Sr (CF 3 COO) 2 , 10mL oleic acid and 10mL octadecene were added to a 100mL three-neck flask, heated to 100°C for 30 minutes under the protection of nitrogen atmosphere to remove water and oxygen, then continue to heat to 280°C and hold for 2 hours to generate strontium fluoride SrF 2 Nanocrystalline: After cooling to room temperature, quickly add a mixture of 0.5mmol trichloroacetic acid, 10mL oleic acid and 10mL octadecene, and heat to 100°C for 30 minutes under the protection of nitrogen atmosphere to remove water and oxygen. Continue heating to 250°C under protection and keep it warm for 30 minutes to generate strontium fluoride chloride SrFCl nanocrystals; the obtained nanocrystals are washed with a mixture of ethanol and cyclohexane, and dried at 60°C to obtain the final product.

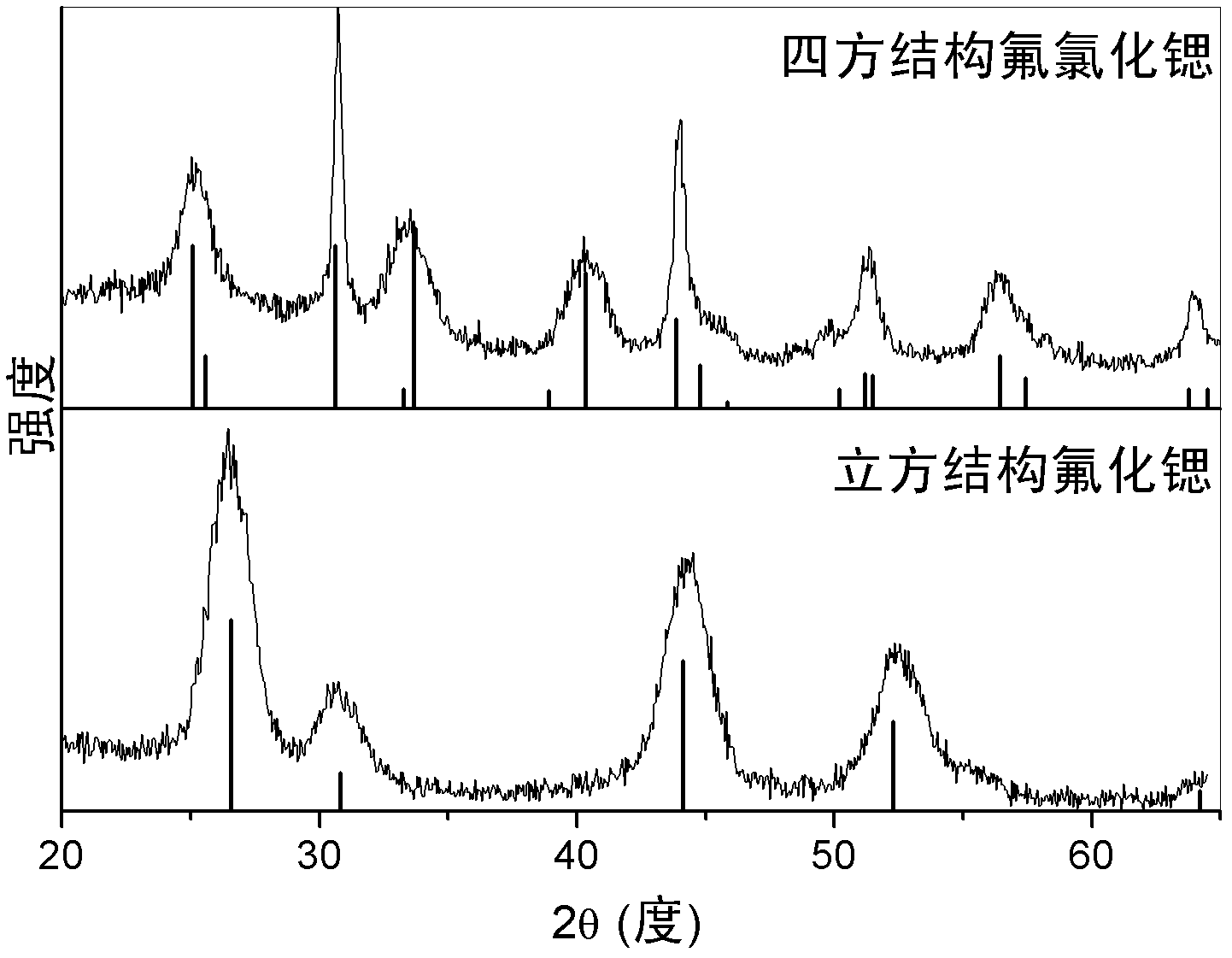

[0017] Powder X-ray diffraction pattern ( figure 1 ) analysis showed that the samples before and after chlorination were SrF 2 and SrFCl...

example 2

[0018] Example 2: 0.1mmol strontium trifluoroacetate Sr (CF 3 COO) 2 , 10mL oleic acid and 10mL octadecene were added to a 100mL three-neck flask, heated to 100°C for 30 minutes under the protection of nitrogen atmosphere to remove water and oxygen, then continue to heat to 280°C and hold for 2 hours to generate strontium fluoride SrF 2 Nanocrystalline: after cooling to room temperature, quickly add a mixture of 0.1mmol trichloroacetic acid, 10mL oleic acid and 10mL octadecene, and heat to 100°C under the protection of nitrogen atmosphere for 30 minutes to remove water and oxygen. Continue heating to 250°C under protection and keep it warm for 30 minutes to generate strontium fluoride chloride SrFCl nanocrystals; the obtained nanocrystals are washed with a mixture of ethanol and cyclohexane, and dried at 60°C to obtain the final product.

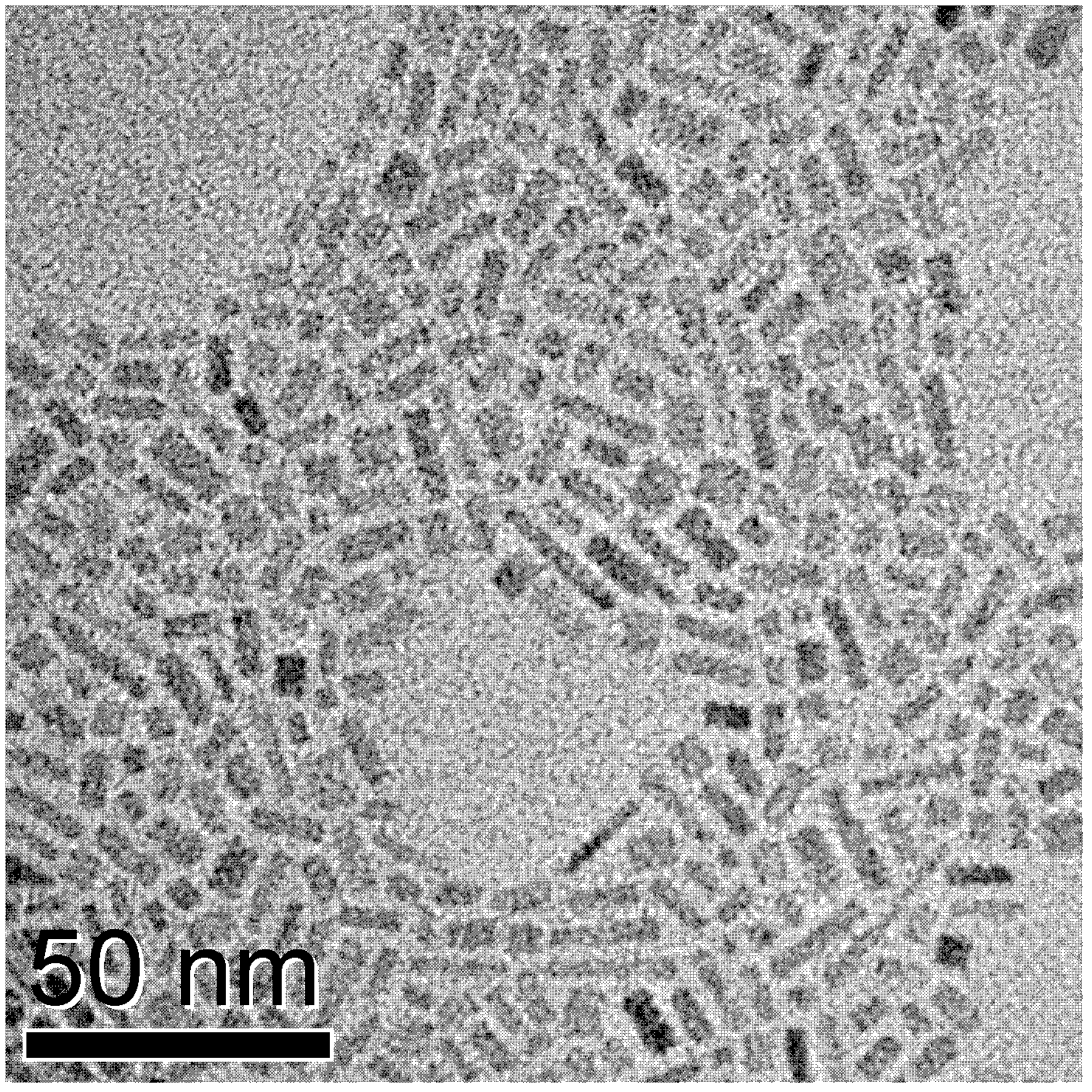

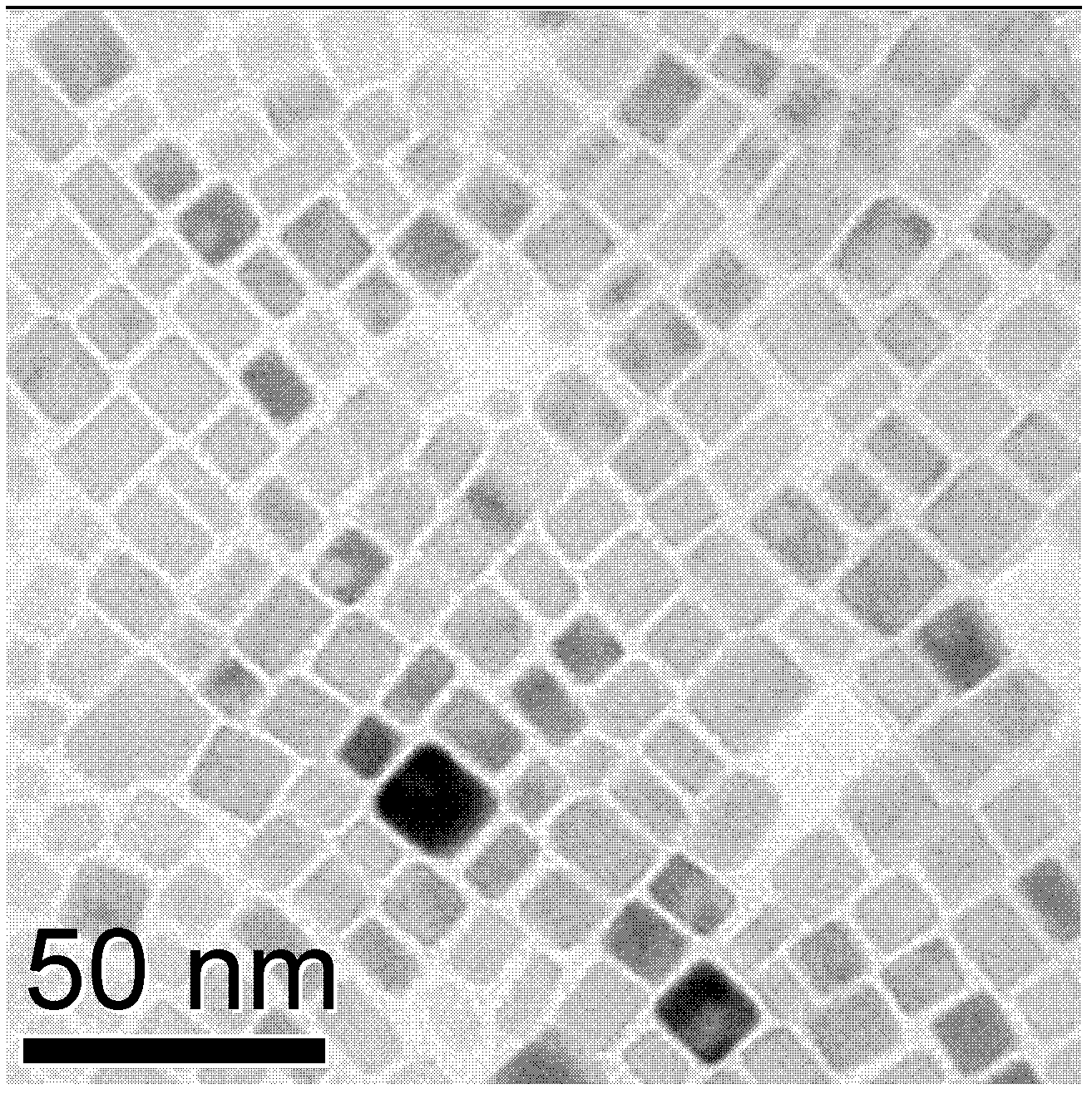

[0019] Powder X-ray diffraction analysis showed that the chlorinated product was pure SrFCl phase; transmission electron microscope observ...

example 3

[0020] Example 3: 1.0mmol strontium trifluoroacetate Sr (CF 3 COO) 2 , 10mL oleic acid and 10mL octadecene were added to a 100mL three-neck flask, heated to 100°C for 30 minutes under the protection of nitrogen atmosphere to remove water and oxygen, then continue to heat to 280°C and hold for 2 hours to generate strontium fluoride SrF 2 Nanocrystalline: After cooling to room temperature, quickly add a mixture of 1.0mmol trichloroacetic acid, 10mL oleic acid and 10mL octadecene, and heat to 100°C for 30 minutes under the protection of nitrogen atmosphere to remove water and oxygen. Continue heating to 250°C under protection and keep it warm for 30 minutes to generate strontium fluoride chloride SrFCl nanocrystals; the obtained nanocrystals are washed with a mixture of ethanol and cyclohexane, and dried at 60°C to obtain the final product.

[0021] Powder X-ray diffraction analysis showed that the chlorinated product was pure SrFCl phase; transmission electron microscope observ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap