A method for producing l-2-aminobutyric acid by a double-immobilized multi-enzyme system

A multi-enzyme system, aminobutyric acid technology, applied in the biological field, can solve the problems of increased separation and purification burden, low coenzyme regeneration efficiency, poor enzyme activity stability, etc., to reduce separation and purification steps, improve accessibility, and improve regeneration efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

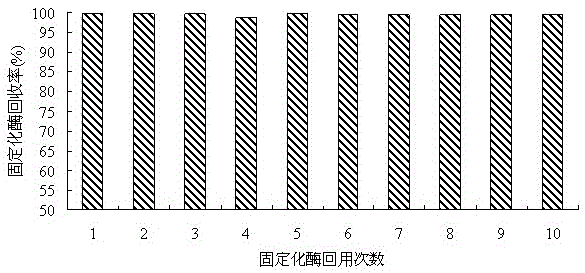

Image

Examples

Embodiment 1

[0028] Example 1: Preparation of co-immobilized multi-enzyme system of threonine deaminase and leucine dehydrogenase.

[0029] Dissolve EudragitS-100 with 0.05mol / L, pH8.0 phosphate buffer, the concentration of EudragitS-100 is 20g / L, and the volume ratio is 1:1, and the threonine deaminase containing 20IU / mL and Enzyme solution of 50 IU / mL leucine dehydrogenase was thoroughly mixed, and incubated at 25° C. and pH 8.0 for 0.2 hours. After incubation, adjust the pH of the solution to be lower than 6.0 with 0.1 mol / L phosphoric acid solution, let it stand for 2 hours to obtain a suspension, centrifuge at 8000 r / min for 30 minutes, and filter to obtain solid microspheres. According to the mass volume ratio of 1g:5mL, 0.05mol / L, pH6.0 phosphate buffer was added to wash the microspheres, and the suspension was centrifuged at 8000r / min for 30 minutes. The washing process was repeated three times to obtain a co-immobilized multi-enzyme system. Store at 4°C for later use.

Embodiment 2

[0030] Example 2: Preparation of co-immobilized multi-enzyme system of threonine deaminase and leucine dehydrogenase

[0031] Dissolve EudragitS-100 with 0.05mol / L, pH8.0 phosphate buffer, the concentration of EudragitS-100 is 20g / L, and the volume ratio is 1:5, and the threonine deaminase containing 80IU / mL and 90 IU / mL leucine dehydrogenase enzyme solution was thoroughly mixed, and incubated at 25° C. and pH 8.0 for 2 hours. After incubation, adjust the pH of the solution to be lower than 6.0 with 0.1 mol / L phosphoric acid solution, let it stand for 2 hours to obtain a suspension, centrifuge at 8000 r / min for 30 minutes, and filter to obtain solid microspheres. According to the mass volume ratio of 1g:5mL, 0.05mol / L, pH6.0 phosphate buffer was added to wash the microspheres, and the suspension was centrifuged at 8000r / min for 30 minutes. The washing process was repeated three times to obtain a co-immobilized multi-enzyme system. Store at 4°C for later use.

Embodiment 3

[0032] Example 3: Preparation of co-immobilized multi-enzyme system of threonine deaminase and leucine dehydrogenase

[0033] Dissolve EudragitS-100 with 0.05mol / L, pH8.0 phosphate buffer, the concentration of EudragitS-100 is 20g / L, and the volume ratio is 1:10, and the threonine deaminase containing 200IU / mL and The enzyme solution of 150 IU / mL leucine dehydrogenase was thoroughly mixed, and incubated at 25° C. and pH 8.0 for 6 hours. After incubation, adjust the pH of the solution to be lower than 6.0 with 0.1 mol / L phosphoric acid solution, let it stand for 2 hours to obtain a suspension, centrifuge at 8000 r / min for 30 minutes, and filter to obtain solid microspheres. According to the mass volume ratio of 1g:5mL, 0.05mol / L, pH6.0 phosphate buffer was added to wash the microspheres, and the suspension was centrifuged at 8000r / min for 30 minutes. The washing process was repeated three times to obtain a co-immobilized multi-enzyme system. Store at 4°C for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com