Pretreatment method of copper insert of storage battery terminal

A copper insert and pretreatment technology, applied in battery pack parts, electrical components, circuits, etc., can solve the problems of penetration corrosion of copper parts, reduce the effective cross-sectional area of current flow, and complex processes, so as to improve the contact ability. and bonding strength, ensuring effective cross-sectional area, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

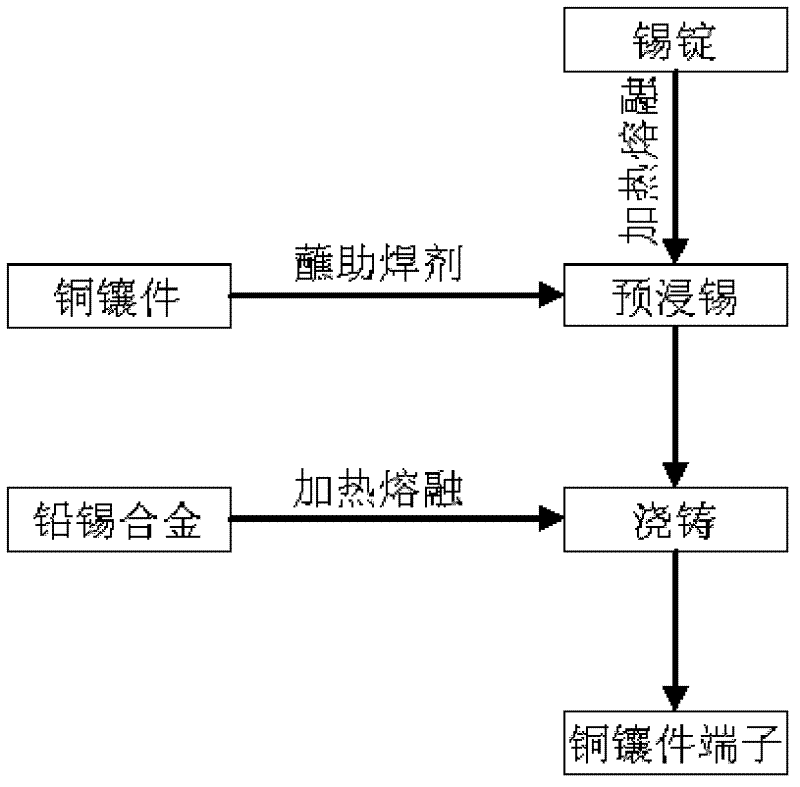

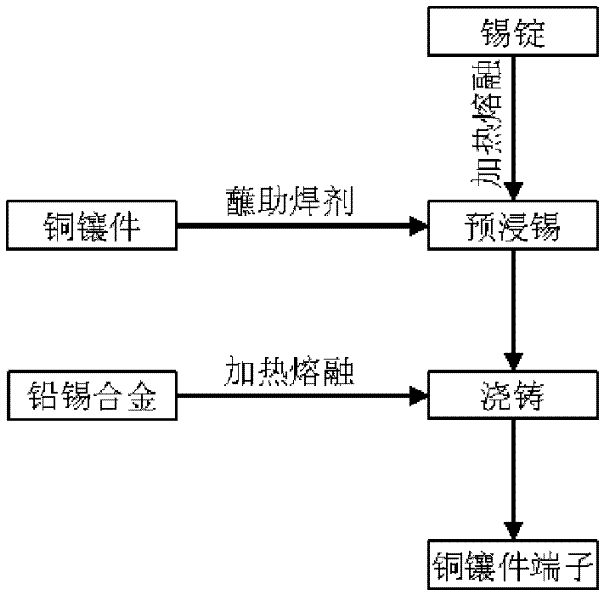

Image

Examples

Embodiment 1

[0019] Dip the part of the copper insert to be cast into the lead alloy with a little flux, and then immerse it in the tin liquid at 320°C for 3s. After the pretreated copper insert is taken out, it is put into the terminal mold, and the lead alloy liquid is cast. The proportion of the soldering flux is as follows: rosin 0.02%, isopropanol 99.0%, polyethylene glycol 0.01%, and the balance is activator adipic acid.

[0020] After the battery terminal was formed, it was dissected and observed, and it was found that there was no gap between the lead alloy and the copper insert.

Embodiment 2

[0022] Dip the part of the copper insert to be cast into the lead alloy with a little flux, and then immerse it in the tin liquid at 240°C for 3s. After the pretreated copper insert is taken out, it is put into the terminal mold, and the lead alloy liquid is cast. Wherein the flux proportion is mass parts: 30% of deionized water, 65% of ethanol, 4% of succinic acid, 0.2% of glycerin, 0.4% of polyethylene glycol, and 0.4% of dioctyl phosphate.

[0023] After the battery terminal was formed, it was dissected and observed, and it was found that there was no gap between the lead alloy and the copper insert.

Embodiment 3

[0025] Dip the part of the copper insert to be cast into the lead alloy with a little rosin solder paste or solder paste, then immerse it in 300°C tin liquid for 4s, take it out, put it into the terminal mold, and cast the lead alloy liquid. After the battery terminal is formed, it is dissected to observe that there is no gap between the lead alloy and the copper insert.

[0026] In addition, the present invention also uses glutaric acid, sebacic acid, pimelic acid, malic acid, o-hydroxybenzoic acid, etc. There is no gap between the alloy and the copper insert.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com