Method for preparing Cd Te nano-wire and Cd Te-based core-shell type nano-wire by liquid-phase non-catalysis

A nanowire and core-based technology, which is applied in the field of preparing CdTe nanowires and CdTe-based core-shell nanowires by liquid-phase non-catalytic method, can solve the problems of poor matching and achieve uniform and dense coating, adjustable composition, and length thickness controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

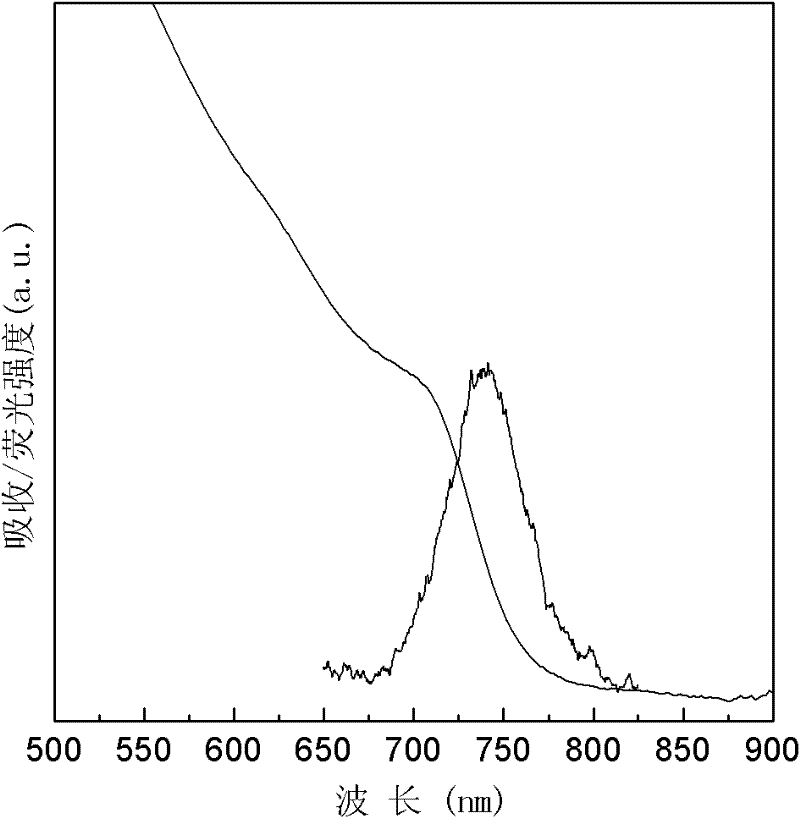

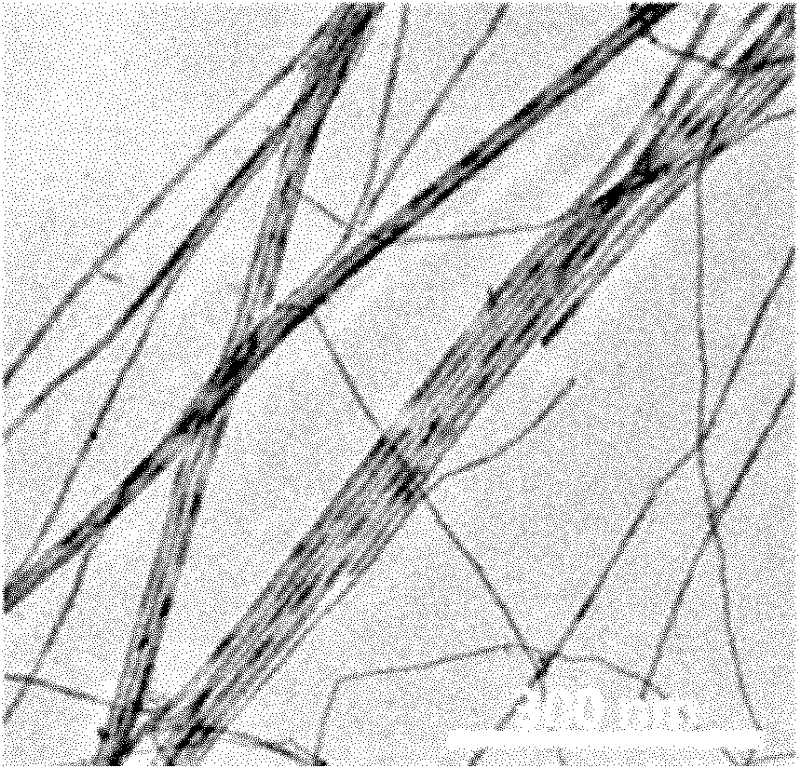

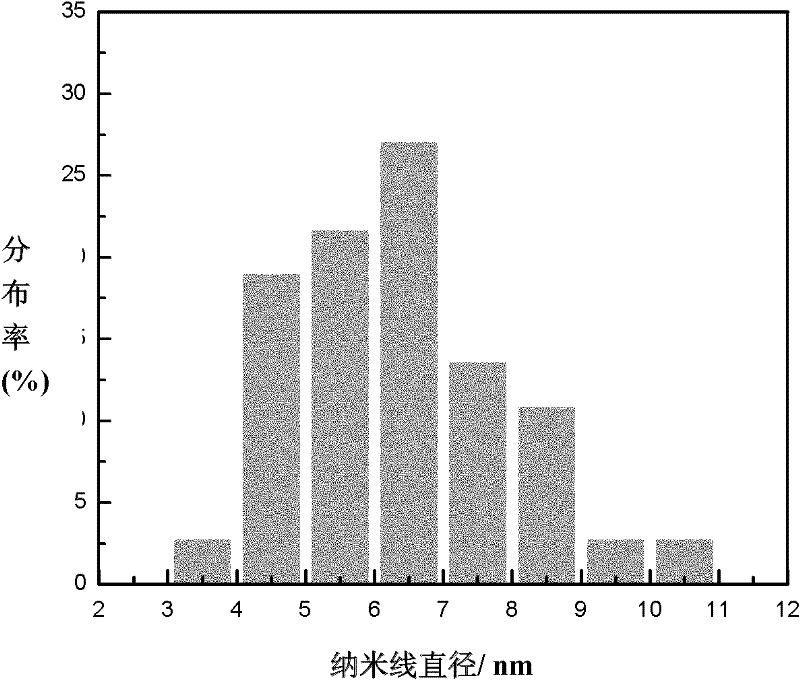

[0042] Embodiment 1, average diameter is the preparation of 6.5nm CdTe nanowire

[0043] (1) Preparation of cadmium precursor: 2mmol Cd(Ac) 2 Or CdO, 6mmol stearic acid and 0.6g n-tetradecyl phosphoric acid (2.16mmol) are mixed and added to the container (wherein Cd(Ac) 2 , the molar ratio of stearic acid and alkylphosphonic acid is 1:3:1.08), under the protection of inert gas, stir and heat to clarification, then drop to room temperature to obtain a white solid, which is the precursor of cadmium-organometallic cadmium ;

[0044] (2) Preparation of tellurium precursor solution: 0.5mmol tellurium powder and 2mL tri-n-octyl / butylphosphine were added to a container filled with argon or nitrogen, and the mixture was heated and stirred until clear (light yellow-green solution), Cool to room temperature, which is the precursor solution of tellurium-tri-n-octyl / butylphosphine tellurium solution;

[0045] (3) Injection pyrolysis of precursor solution: add an appropriate amount of t...

Embodiment 2

[0046] Embodiment 2, average diameter is the preparation of 8.5nm CdTe nanowire

[0047] Concrete steps are with embodiment 1, difference is that in step (1) Cd(Ac) 2 Or the amount of CdO, stearic acid and alkyl phosphonic acid is respectively 2mmol, 4mmol, 3mmol, and the amount of tellurium powder is 0.2mmol in the step (2), and the reaction time is 10min in the step (3); Gained nanowire average length is about It is 10 μm, the average diameter is about 8.5nm, and its aspect ratio is about 1100:1.

Embodiment 3

[0048] Embodiment 3, average diameter is the preparation of 11nm CdTe nanowire

[0049] Concrete steps are with embodiment 1, difference is that in step (1) Cd(Ac) 2 Or the amount of CdO, stearic acid and alkyl phosphonic acid is respectively 2mmol, 8mmol, 1mmol, and the amount of tellurium powder is 0.6mmol in the step (2), and the reaction time is 20min in the step (3); Gained nanowire average length is about It is 10 μm, the average diameter is about 11 nm, and its aspect ratio is about 900:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com