Method for preparing nanometer flaky yttrium oxide powder

A nano-flaky, yttrium oxide technology, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problem that the microscopic morphology of nano-yttrium oxide powder has not been effectively controlled, and there is no commercial nano-flaky yttrium oxide. Powder sales and other issues, to achieve the effect of strong repeatability and operability, low preparation cost, and low reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

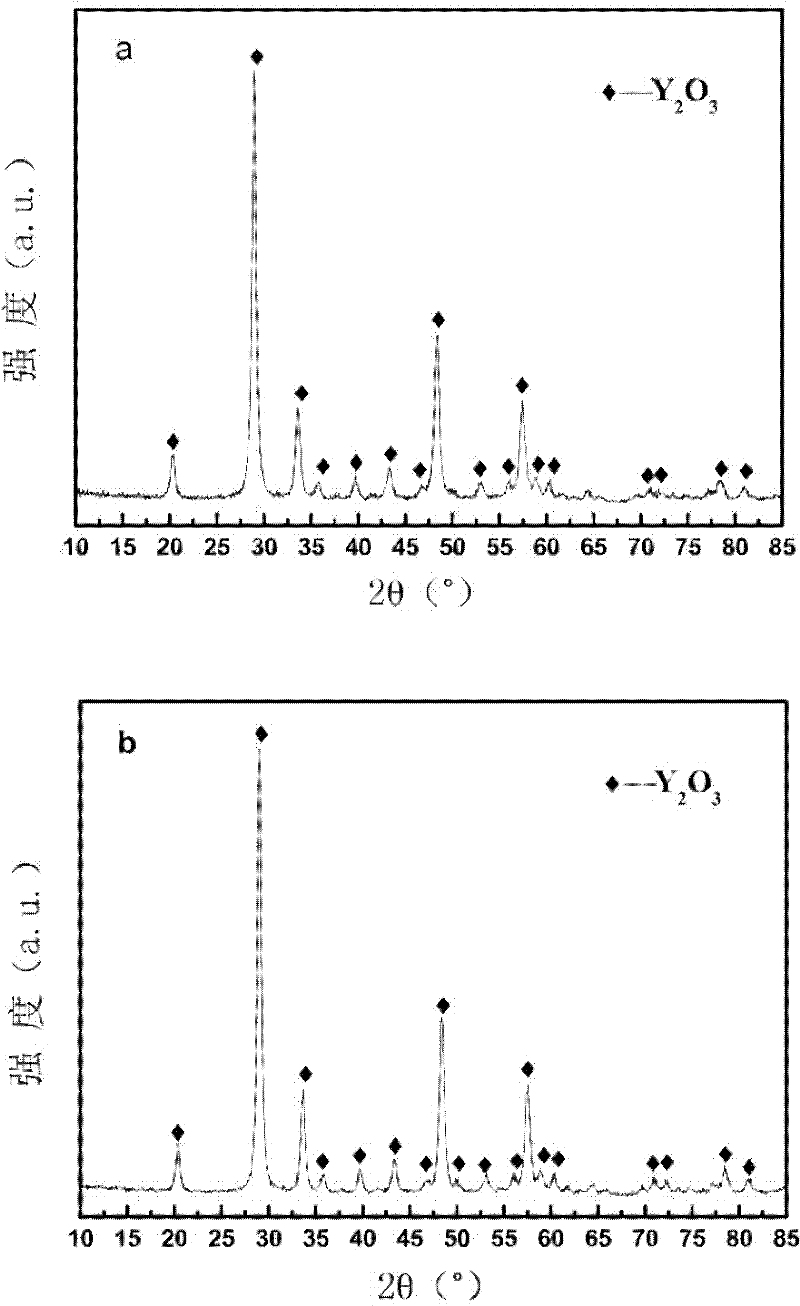

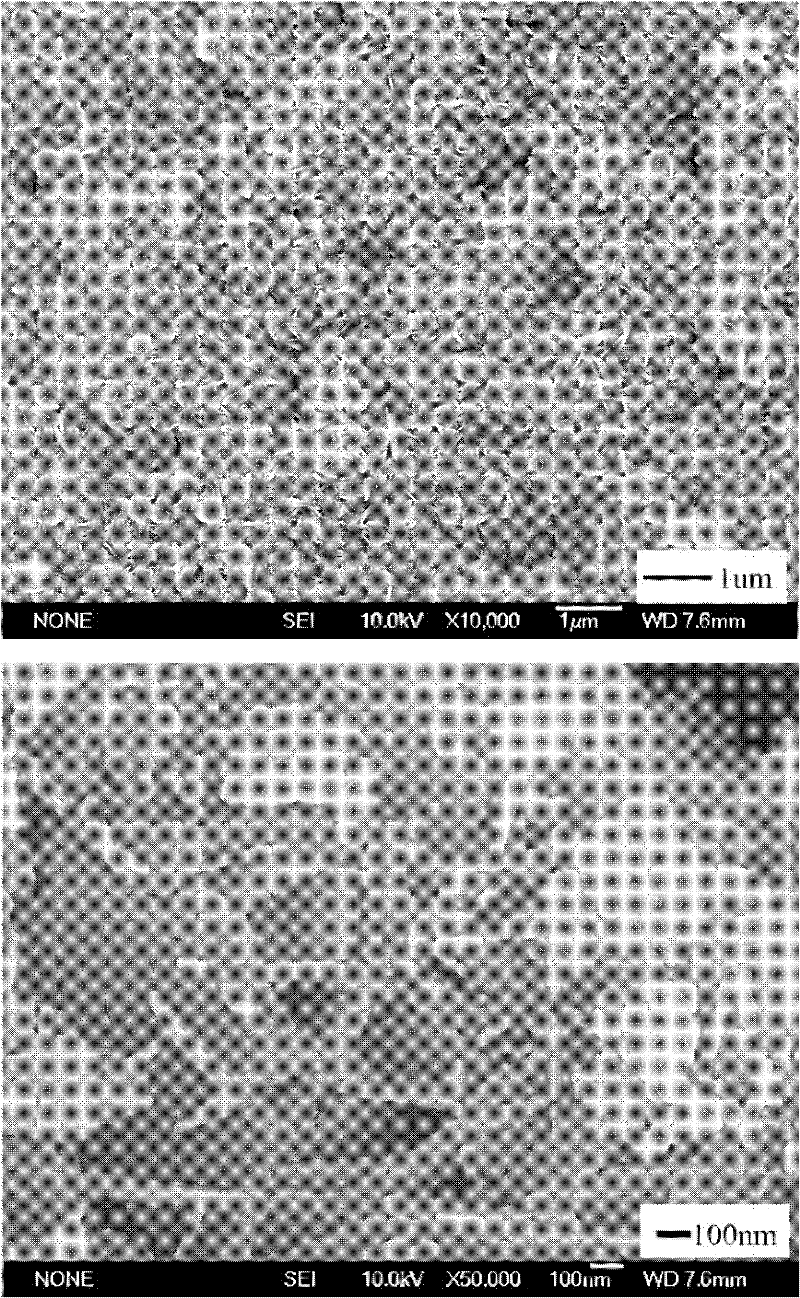

[0025] Prepare a yttrium nitrate solution with a concentration of 0.20 mol / L, add dropwise an ammonia solution with a content of 25%, and adjust the pH value of the yttrium salt solution to 7. After the white colloidal substance was formed, the suspension was transferred to a hydrothermal reactor, subjected to hydrothermal treatment at 140°C for 24 hours, cooled to room temperature, and centrifuged to separate the precursor. The obtained precursor was washed 4 times with deionized water and 3 times with absolute ethanol, so as to fully remove residual acid ion impurities. After drying, it was calcined at 600°C for 4 hours to obtain nano-flaky yttrium oxide powder. It can be seen from the XRD diffraction pattern analysis that the powder sample is pure Y 2 o 3 phase, no other impurity phases such as figure 1 (a) shown. Putting the powder sample under a scanning electron microscope, it can be seen that the microscopic morphology of the powder sample is flake-like, the particl...

Embodiment 2

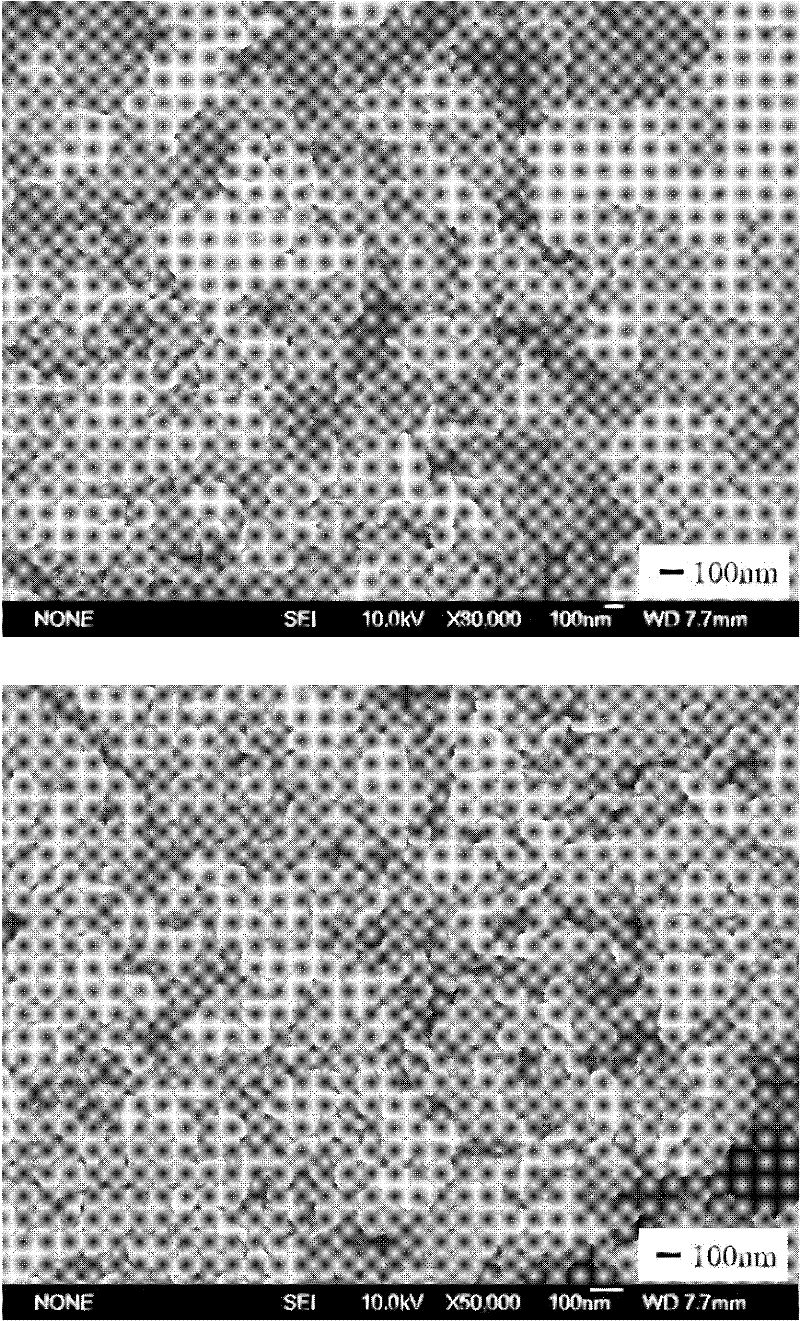

[0027] Prepare yttrium nitrate solution with a concentration of 0.20mol / L, add dropwise an ammonia solution with a content of 25%, adjust the pH to 9, and generate a white jelly, then transfer the suspension to a hydrothermal reaction kettle, and heat After heat treatment in water for 24 h, the precursor was separated by centrifugation after cooling to room temperature. The precursor was washed 4 times with deionized water and 3 times with absolute ethanol to fully remove residual acid radical impurities. After drying, it was calcined at 600°C for 4 hours to obtain nano-flaky yttrium oxide powder. It can be seen from the XRD diffraction pattern analysis that the powder sample is pure Y 2 o 3 phase, and no other impurity phases such as figure 1 (b). Putting the powder sample under the scanning electron microscope, it can be seen that the microscopic morphology of the powder sample is flake, the particle size is 100-200nm, the slice thickness is 10nm, the ratio of grain diam...

Embodiment 3

[0029] The yttrium nitrate solution in Example 1 was replaced with yttrium sulfate solution, and the implementation process was the same to obtain flaky yttrium oxide powder. The obtained flaky yttrium oxide powder has a particle diameter of 200-300nm, a sheet thickness of 10-20nm, and a grain diameter-to-thickness ratio of about 15-20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com