Method for preparing sodium bismuth titanate nanometer sheet

A technology of sodium bismuth titanate and nanosheets, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve problems such as large environmental pollution, and achieve the effects of no environmental pollution, simple equipment and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

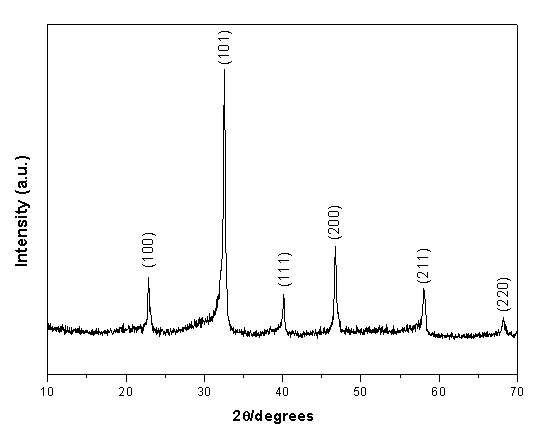

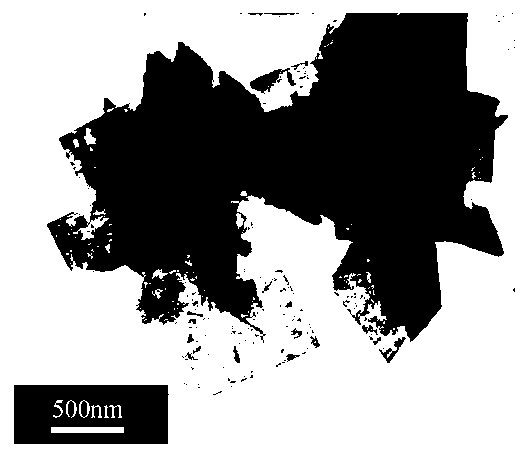

Image

Examples

Embodiment 1

[0020] 1) Titanium sulfate is dissolved in 0.3wt% dilute nitric acid solution to adjust the Ti in the solution 4+ The ion concentration is 0.2mol / L;

[0021] 2) Under stirring, add an aqueous sodium hydroxide solution to the dilute nitric acid solution of titanium sulfate prepared in step 1), so that the pH value of the solution is 14, filter and wash the obtained precipitate, and obtain a titanium oxyhydroxide precipitate;

[0022] 3) dissolving bismuth nitrate in distilled water to form an aqueous solution of bismuth nitrate, adjusting the concentration of bismuth ions in the solution to be 0.2mol / L;

[0023] 4) Under stirring state, add aqueous sodium hydroxide solution to the bismuth nitrate aqueous solution prepared in step 3), make the pH value of the solution 14, filter and wash the precipitate obtained to obtain the oxyhydroxide precipitation of bismuth;

[0024] 5) The oxyhydroxide precipitation of titanium and bismuth, sodium hydroxide are added in the reactor liner...

Embodiment 2

[0027] 1) Titanium sulfate is dissolved in 0.3wt% dilute nitric acid solution to adjust the Ti in the solution 4+ The ion concentration is 0.5mol / L;

[0028] 2) Under stirring, add an aqueous sodium hydroxide solution to the dilute nitric acid solution of titanium sulfate prepared in step 1), so that the pH value of the solution is 14, filter and wash the obtained precipitate, and obtain a titanium oxyhydroxide precipitate;

[0029] 3) dissolving bismuth nitrate in distilled water to form an aqueous solution of bismuth nitrate, adjusting the concentration of bismuth ions in the solution to be 0.6mol / L;

[0030] 4) Under stirring state, add aqueous sodium hydroxide solution to the bismuth nitrate aqueous solution prepared in step 3), make the pH value of the solution 14, filter and wash the precipitate obtained to obtain the oxyhydroxide precipitation of bismuth;

[0031] 5) The oxyhydroxide precipitation of titanium and bismuth, sodium hydroxide are added in the reactor liner...

Embodiment 3

[0034] 1) Titanium sulfate is dissolved in 0.3wt% dilute nitric acid solution to adjust the Ti in the solution 4+ The ion concentration is 0.7mol / L;

[0035] 2) Under stirring, add an aqueous sodium hydroxide solution to the dilute nitric acid solution of titanium sulfate prepared in step 1), so that the pH value of the solution is 14, filter and wash the obtained precipitate, and obtain a titanium oxyhydroxide precipitate;

[0036] 3) dissolving bismuth nitrate in distilled water to form an aqueous solution of bismuth nitrate, adjusting the concentration of bismuth ions in the solution to be 0.4mol / L;

[0037] 4) Under stirring, add aqueous sodium hydroxide solution to the bismuth nitrate aqueous solution prepared in step 3), so that the pH value of the solution is 14, filter and wash the obtained precipitate, and obtain a bismuth oxyhydroxide precipitate;

[0038] 5) The oxyhydroxide precipitation of titanium and bismuth, sodium hydroxide are added in the reactor liner, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com