Preparation method for 0-3 compound multiple-ferrite ceramic of cobalt ferrite and lead lanthanum zironate titanate

A technology of lead lanthanum zirconate titanate and multiferroic ceramics is applied in the field of ferroelectric/ferromagnetic composite materials, which can solve the problems of complex processing technology degradation factors, uneven phase dispersion, phase reaction and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the high magnetoelectric conversion coefficient composite multiferroic ceramics comprises the following steps:

[0024] (1) Preparation of PLZT powder

[0025] Use analytically pure lead oxide, titanium dioxide, zirconium dioxide, lanthanum trioxide, and niobium pentoxide as raw materials, adopt the traditional mixed oxide sintering process, pre-fire at 850°C for 3 hours after mixing, and pulverize the powder and zirconia balls (diameter 3mm, 5mm, 10mm mass ratio is 4:2:1) into a nylon ball mill jar at a mass ratio of 1:4, and use water as the medium to grind for 2 hours to obtain an average particle size of 0.8- 1.2 micron lead zirconate titanate powder.

[0026] (2) Preparation of CFO powder

[0027] Will Fe 2 o 3 Mixed with CoO at a molar ratio of 1:1, pre-fired at 850°C for 2h, sintered at 1275°C for 2h, CoFe 2 o 4 Put the powder into a stainless steel tank, add 3-4 times the mass of steel balls (the mass ratio of steel balls with dia...

example

[0035] Using analytically pure lead oxide, titanium dioxide, zirconium dioxide, lanthanum trioxide, and niobium pentoxide as raw materials, LiBiO was prepared according to the above steps 3 Doped PLZT and zirconia-coated CFO powders.

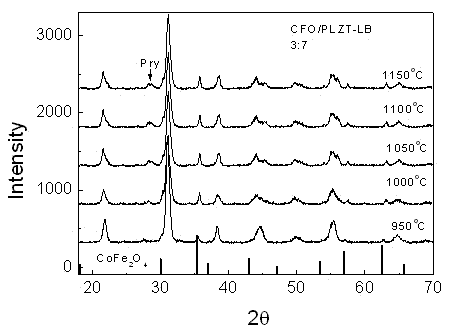

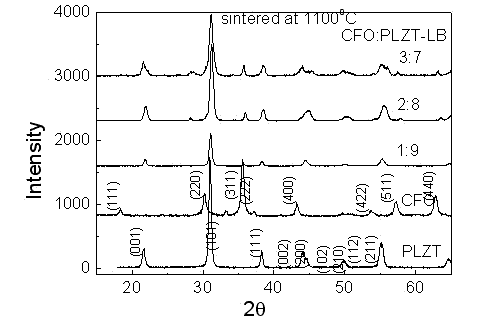

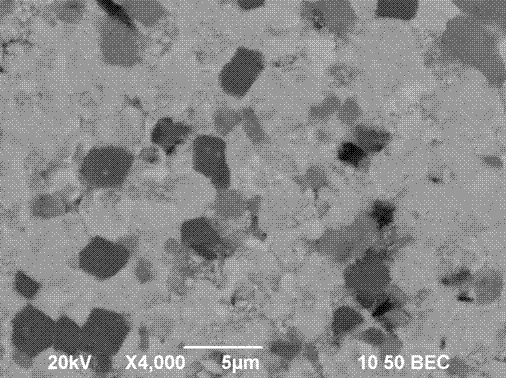

[0036] Mix the two powders according to the mass ratio CFO:PLZT=1 / 9, 2 / 8, 3 / 7 and 4 / 6 (volume ratio 14.4 / 85.6, 27.4 / 72.6 and 39.3 / 60.7), and add polyvinyl alcohol (5%) aqueous solution, granulated and pressed to make discs with a diameter of 11 mm and a thickness of 1.5 mm, and sintered at 850-1150 ° C for 15 minutes to obtain composite ceramic discs; for comparison, the quality of all samples is the same as the original size .

Embodiment 1

[0037] Example 1 CFO: PLZT=1 / 9

[0038] (1) Preparation of PLZT powder

[0039] Using analytically pure 127.77g of lead oxide, 20.58g of titanium dioxide, 43.83g of zirconium dioxide, 6.15g of lanthanum trioxide and 1.67g of niobium pentoxide as raw materials, the traditional mixed oxide sintering process was adopted, and the mixture was mixed at 850 Pre-fired at ℃ for 3 hours, crushed powder and zirconia balls (diameter: 3mm, 5mm, 10mm, mass ratio: 4:2:1) were put into nylon ball mill tank according to the mass ratio of 1:4, and water was used as the medium for milling 2 Hours, the lead zirconate titanate powder (Pb 0.91 La 0.06 (Zr 0.58 Ti 0.42 ) 0.975 Nb 0.02 o 3 ).

[0040] (2) Preparation of CFO powder

[0041] Will Fe 2 o 3 Mixed with CoO at a molar ratio of 1:1, pre-fired at 850°C for 2h, sintered at 1275°C for 2h, CoFe 2 o 4 Put the powder into a stainless steel tank, add 3 times the mass of steel balls (the mass ratio of steel balls with diameters of 2mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com