Method utilizing column chromatography to prepare high-purity L-alpha glyceryl phosphoryl ethanolamine

A technology of glycerol phosphatidylethanolamine and column chromatography, which is applied in the field of deep processing of phospholipids, can solve problems such as L-α-GPE research reports that have not yet appeared, and achieve the effects of high industrial development prospects, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

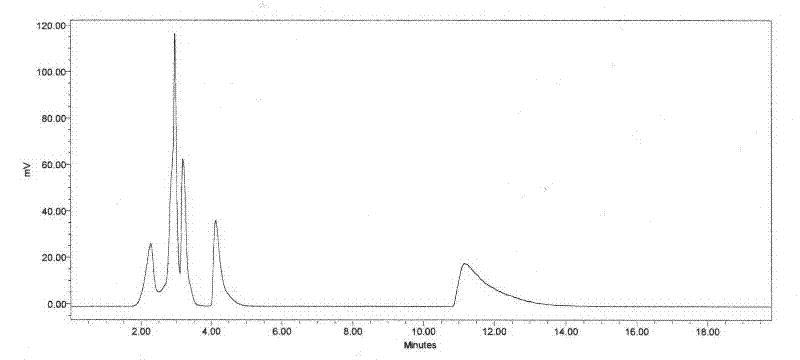

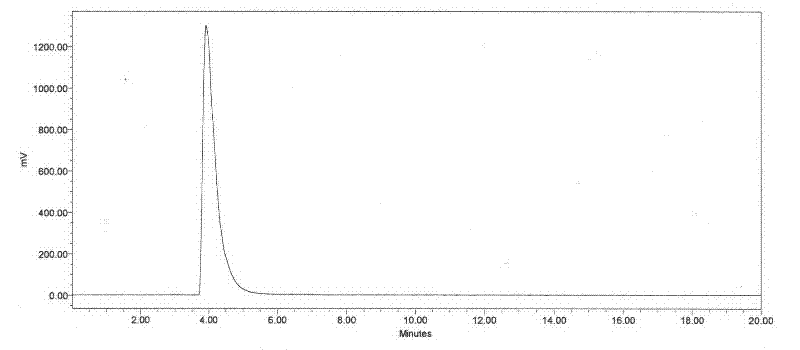

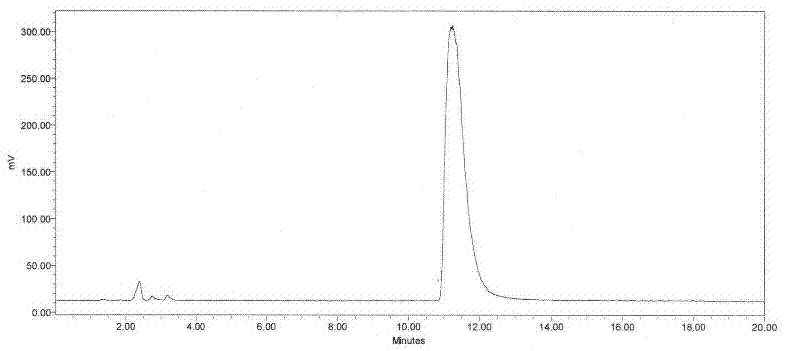

Image

Examples

Embodiment 1

[0018] Weigh 250g of soybean powder phospholipids into a beaker, add 1L of anhydrous methanol, stir quickly to make the powder phospholipids in the system evenly diffuse, then add 12g of sodium methoxide, stir at 35°C for 6h, and filter with suction, adjust the pH of the obtained clear liquid to 9 about. Measure 200ml of methanol-soaked D001 resin, pack it into a column, wash the column with 400ml of methanol, and load the alcoholysis solution of soybean powder phospholipids at a flow rate of 1.5mL / min. After loading, first elute with 1L methanol, and then use The column was desorbed with ultrapure water at pH=6.78. Load the desorbed liquid again into a chromatographic column (washed with 400mL water) equipped with 100mL201×7 resin, and the effluent under the column is GPC aqueous solution. After loading the sample, wash it with water until the GPC flows out completely. The purity of GPC is 97.11 %, and then desorbed with 1% acetic acid, the resulting desorbed solution was GP...

Embodiment 2

[0020] Weigh 250g of soybean powder phospholipids into a beaker, add 1.25L of anhydrous methanol, stir quickly to make the powder phospholipids in the system evenly diffuse, then add 10g of sodium methoxide, stir at 35°C for 19h, and filter with suction, the pH of the obtained clear liquid reaches 8 about. Measure 100ml of D001 resin soaked in methanol, pack it into a column, wash the column with 200ml of methanol, and load the above alcoholysis solution of soybean powder phospholipid at a flow rate of 2.0mL / min. After loading, first elute with 1L methanol, and then use The column was desorbed with ultrapure water at pH=5.01. Load the desorbed solution again into a chromatography column (washed with 400mL water) equipped with 200mL 201×7 resin. The effluent under the column is GPC aqueous solution. After loading the sample, wash it with water until the GPC flows out completely. The purity of GPC is 95.72 %, and then desorbed with 1% acetic acid, the obtained desorbed solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com