Modified graphene/polyimide resin composite material and preparation method thereof

A technology of polyimide resin and composite material, which is applied in the direction of fibrous filler, dyed low molecular organic compound treatment, etc., to achieve the effects of cheap and easy-to-obtain raw materials, simple and easy preparation method, and improved interface bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

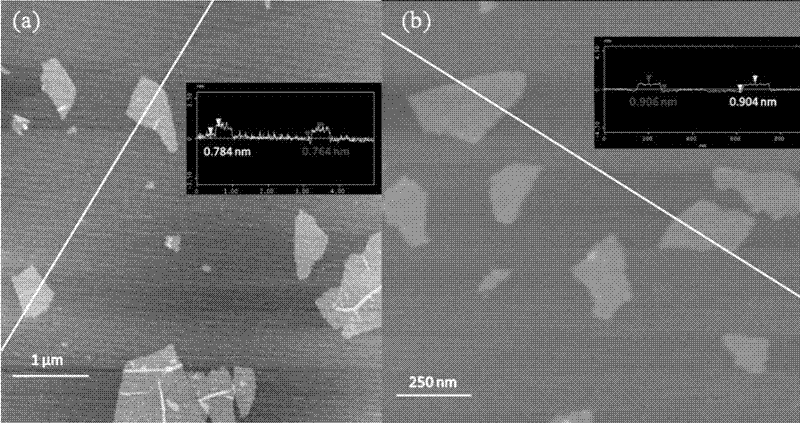

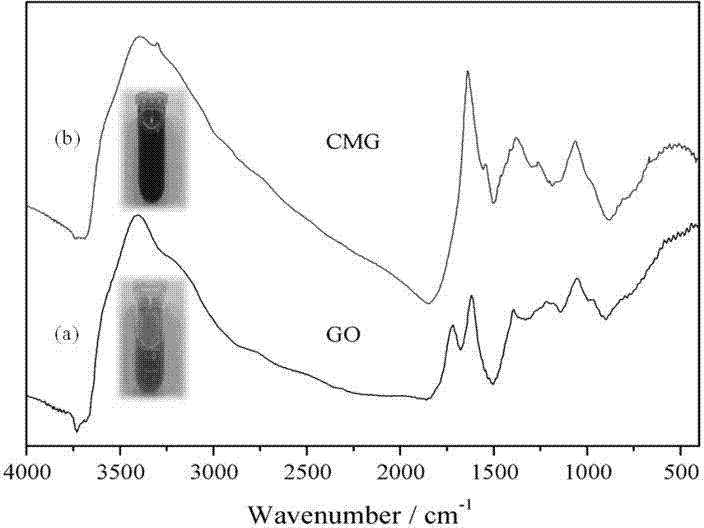

[0032] Step 1: Modification of graphene oxide:

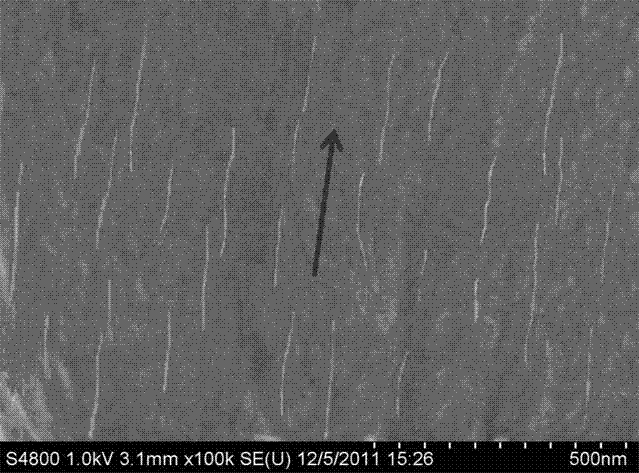

[0033]Weigh a certain amount of graphene oxide and put it into a three-necked round-bottom bottle, add 5ml per 1mg of graphene oxide into N,N-dimethylacetamide, and then use ultrasonic waves to disperse for 1 hour to obtain a stable and uniform dispersion graphene oxide dispersion. Add the weighed 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride, 1-hydroxy-benzo-triazole, triethylamine and ethynylaniline to the above dispersion In, the reaction was stirred at room temperature for 12h. Wherein, by molar ratio, graphene oxide: 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride: 1-hydroxyl-benzo-triazole: triethylamine: Ethynylaniline=1:1.2:1.2:20:5. The reacted dispersion was vacuum filtered to obtain a mixture, which was washed with N,N-dimethylacetamide and deionized water to remove unreacted substances and reaction by-products, and the product was dried in a vacuum oven at 50°C. Prepared modified graphene. ...

Embodiment 2

[0040] Step 1: Modification of graphene oxide:

[0041] Weigh a certain amount of graphene oxide and put it into a round-bottom three-neck bottle, add 7ml per 1mg of graphene oxide into N,N-dimethylformamide, and then use ultrasonic dispersion for 2 hours to obtain a stable and uniform dispersion graphene oxide dispersion. Add the weighed 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride, 1-hydroxy-benzo-triazole, triethylamine and phenylethynylaniline to the above dispersion solution, the reaction was stirred at room temperature for 18h. Wherein, by molar ratio, graphene oxide: 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride: 1-hydroxyl-benzo-triazole: triethylamine: Phenylethynylaniline=1:1.1:1.2:18:8. The reacted dispersion was vacuum filtered to obtain a mixture, which was washed with N,N-dimethylformamide and deionized water to remove unreacted substances and reaction by-products, and the product was dried in a vacuum oven at 40°C. Prepared modified...

Embodiment 3

[0048] Step 1: Modification of graphene oxide:

[0049] Weigh a certain amount of graphene oxide and put it into a round-bottom three-neck bottle, add 6ml of graphene oxide per 1mg into dimethyl sulfoxide, and then use ultrasonic wave to disperse for 2 hours to obtain stable and uniformly dispersed graphene oxide Dispersions. Add the weighed 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride, 1-hydroxy-benzo-triazole, triethylamine and phenylmaleamidoaniline to In the above dispersion, the reaction was stirred at room temperature for 12 h. Wherein, by molar ratio, graphene oxide: 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride: 1-hydroxyl-benzo-triazole: triethylamine: Benzylmaleamidoaniline=1:1.2:1.1:25:9. The reacted dispersion was vacuum filtered to obtain a mixture, which was washed with dimethyl sulfoxide and deionized water to remove unreacted substances and reaction by-products, and the product was dried in a vacuum oven at 40°C to obtain a modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com