Ferroferric oxide/reduced graphene oxide composite wave-absorbing material with hollow hemisphere structure and preparation method

A technology of composite microwave-absorbing materials and ferroferric oxide, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of microwave absorption performance and electromagnetic shielding performance reporting of composite materials, so as to improve the stealth effect and change the electromagnetic parameters , Improve the effect of absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Weigh 0.01 g of graphene oxide and 0.5 g of P123, put them in a 100 ml beaker, add 60 ml of ethylene glycol, and ultrasonically disperse for 90 minutes;

[0031] 2. Weigh 1.0 g of ferric chloride and 2.0 g of sodium acetate, add to the above solution in turn, and stir rapidly for 60 minutes;

[0032] 3. Transfer the above mixture solution into a 100 ml stainless steel reaction kettle, tighten it, and put it in a blast drying oven at a constant temperature of 180 degrees Celsius for 10 hours;

[0033] 4. Take out the reaction kettle, filter the product with suction, wash with distilled water and absolute ethanol in turn, and then put it in a vacuum drying oven at 80 degrees Celsius for 10 hours in vacuum to obtain a hollow hemispherical ferric oxide / reduced graphene oxide composite Absorbing material.

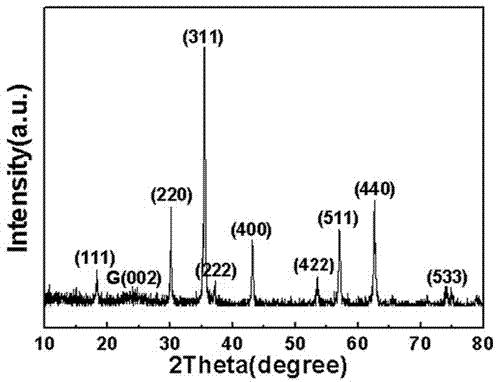

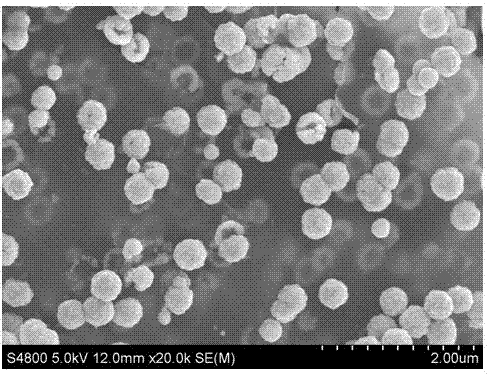

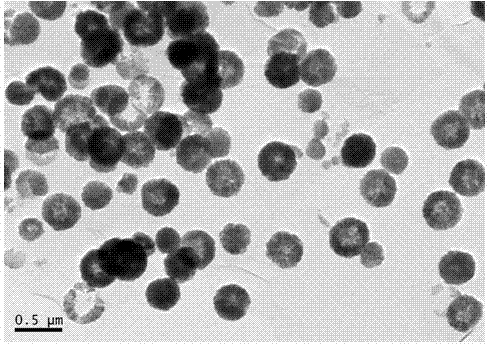

[0034]

Embodiment 2

[0036] 1. Weigh 0.05 g of graphene oxide and 0.5 g of P123, put them in a 100 ml beaker, add 60 ml of ethylene glycol, and ultrasonically disperse for 90 minutes;

[0037] 2. Weigh 1.0 g of ferric chloride and 2.0 g of sodium acetate, add to the above solution in turn, and stir rapidly for 60 minutes;

[0038] 3. Transfer the above mixture solution into a 100 ml stainless steel reaction kettle, tighten it, and put it in a blast drying oven at a constant temperature of 180 degrees Celsius for 10 hours;

[0039] 4. Take out the reaction kettle, filter the product with suction, wash with distilled water and absolute ethanol in turn, and then put it in a vacuum drying oven at 80 degrees Celsius for 10 hours in vacuum to obtain a hollow hemispherical ferric oxide / reduced graphene oxide composite Absorbing material.

[0040]

Embodiment 3

[0042] 1. Weigh 0.1 g of graphene oxide and 0.5 g of P123, put them in a 100 ml beaker, add 60 ml of ethylene glycol, and ultrasonically disperse for 90 minutes;

[0043] 2. Weigh 1.0 g of ferric chloride and 2.0 g of sodium acetate, add to the above solution in turn, and stir rapidly for 60 minutes;

[0044] 3. Transfer the above mixture solution into a 100 ml stainless steel reaction kettle, tighten it, and put it in a blast drying oven at a constant temperature of 180 degrees Celsius for 10 hours;

[0045]4. Take out the reaction kettle, filter the product with suction, wash with distilled water and absolute ethanol in turn, and then put it in a vacuum drying oven at 80 degrees Celsius for 10 hours in vacuum to obtain a hollow hemispherical ferric oxide / reduced graphene oxide composite Absorbing material.

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com