Moisture-proof protection film of SrI2:Eu-doped scintillating crystal and preparation method thereof

A scintillation crystal and strontium iodide technology, which is applied in the field of moisture-proof protective film and its preparation, can solve the problems of easy deliquescence, increase in crystal device size, and long-term use of the crystal, and achieve the effects of easy control, good quality, and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

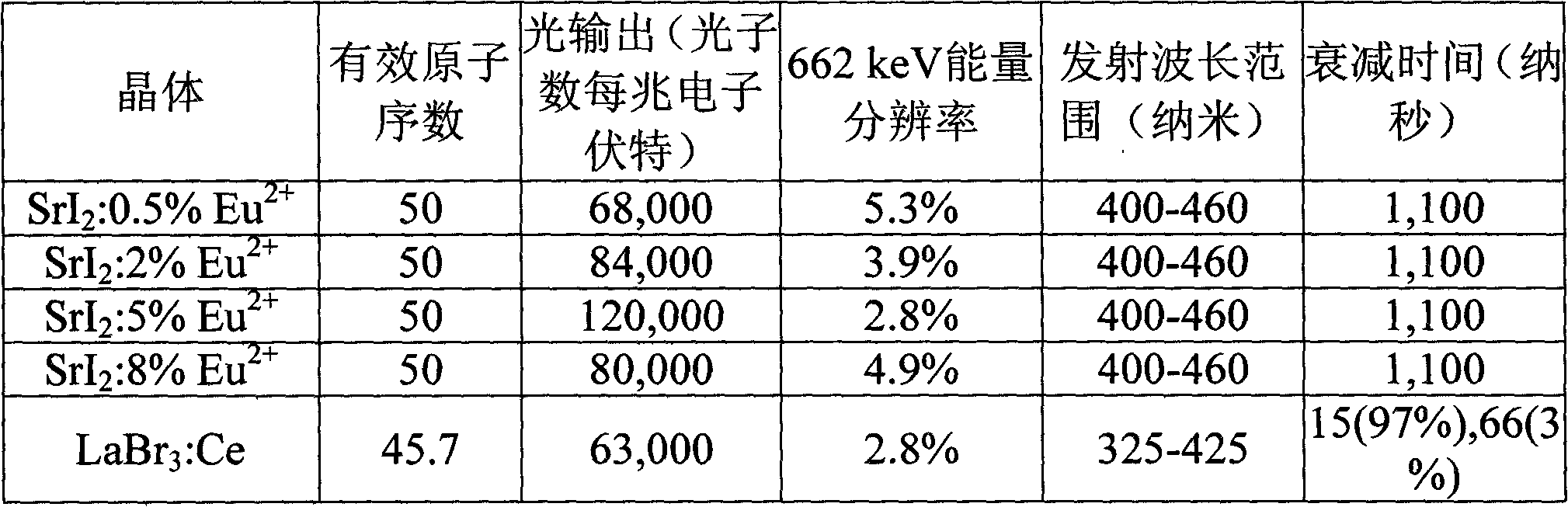

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Process europium-doped strontium iodide crystals into columnar shape with a size of Ф25×25mm 3 , the evaporation system is evacuated to 1×10 -3 Pa, strontium fluoride as the evaporation material, molybdenum evaporation boat, 50W power electron beam evaporation for 0.5 hours, the crystal temperature is 50 °C, first evaporate the crystal cylinder, and then evaporate the end surface. The evaporation process rotates the crystal at a constant speed. A 100nm-thick layer of strontium fluoride is formed on the surface of the crystal. According to X-ray diffraction, the thin film is cubic crystal strontium fluoride. The europium-doped strontium iodide scintillation crystal plated with a strontium fluoride moisture-proof protective film is placed in the air. After three months, the crystal has no deliquescence, the surface is smooth, and the crystal has deliquescence resistance. To test its scintillation performance, the energy resolution at 662KeV gamma rays is 3%, the light o...

Embodiment 2

[0016] Processing 25×25×25mm 3 SrI 2 : Eu crystal, the evaporation system is vacuumed to 9×10 -4 Pa, strontium fluoride with a purity of 99.99% is used as the evaporation material, and the molybdenum evaporation boat is evaporated with a power electron beam of 200W for 30 hours, and the crystal temperature is 400°C. Strontium fluoride is formed on the surface to a thickness of 10 μm. According to X-ray diffraction, the thin film is cubic crystal strontium fluoride. The europium-doped strontium iodide scintillation crystal plated with a strontium fluoride moisture-proof protective film is placed in the air. After one month, the crystal has no deliquescence, the surface is smooth, and the crystal has deliquescence resistance.

Embodiment 3

[0018] Processing 10×10×10mm 3 SrI 2 : Eu crystal, the evaporation system is vacuumed to 5×10 -4 Pa, strontium fluoride with a purity of 99.99% is used as the evaporation material, and the molybdenum evaporation boat is evaporated with a power electron beam of 100W for 10 hours, and the crystal temperature is 200°C. Strontium fluoride is formed on the surface to a thickness of 1 μm. According to X-ray diffraction, the thin film is cubic crystal strontium fluoride. The europium-doped strontium iodide scintillation crystal plated with a strontium fluoride moisture-proof protective film is placed in the air. After one month, the crystal has no deliquescence, the surface is smooth, and the crystal has deliquescence resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com