Method for quickly extracting edible antibacterial peptide from fermentation solution

A technology of antimicrobial peptides and fermentation broth, which is applied in the field of extraction of antimicrobial peptides and rapid separation and preparation of microbial antimicrobial peptides. It can solve the problems of low adsorption rate, difficult desorption, and unsuitability for large-scale production, and achieves low cost and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

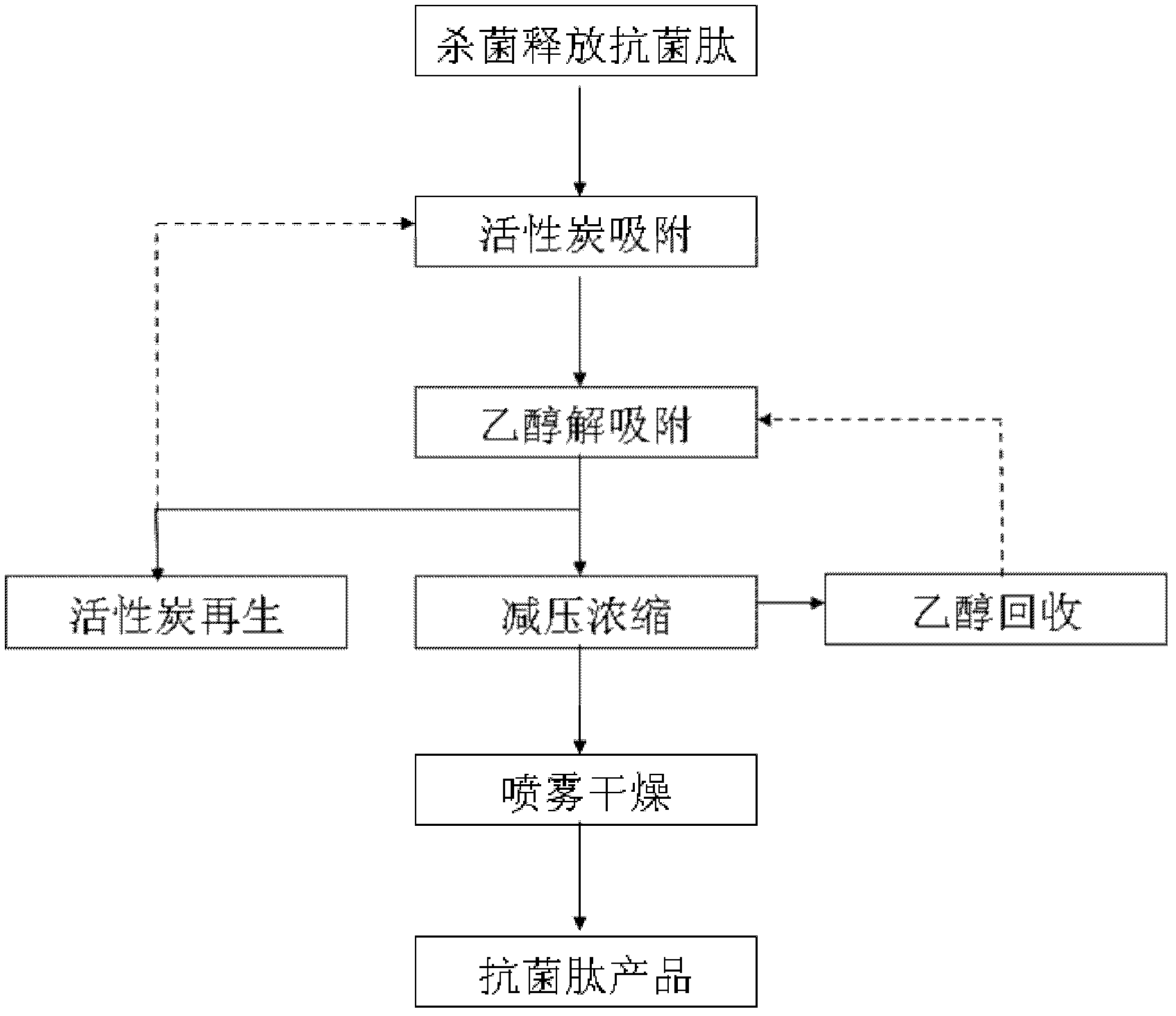

Method used

Image

Examples

Embodiment 1

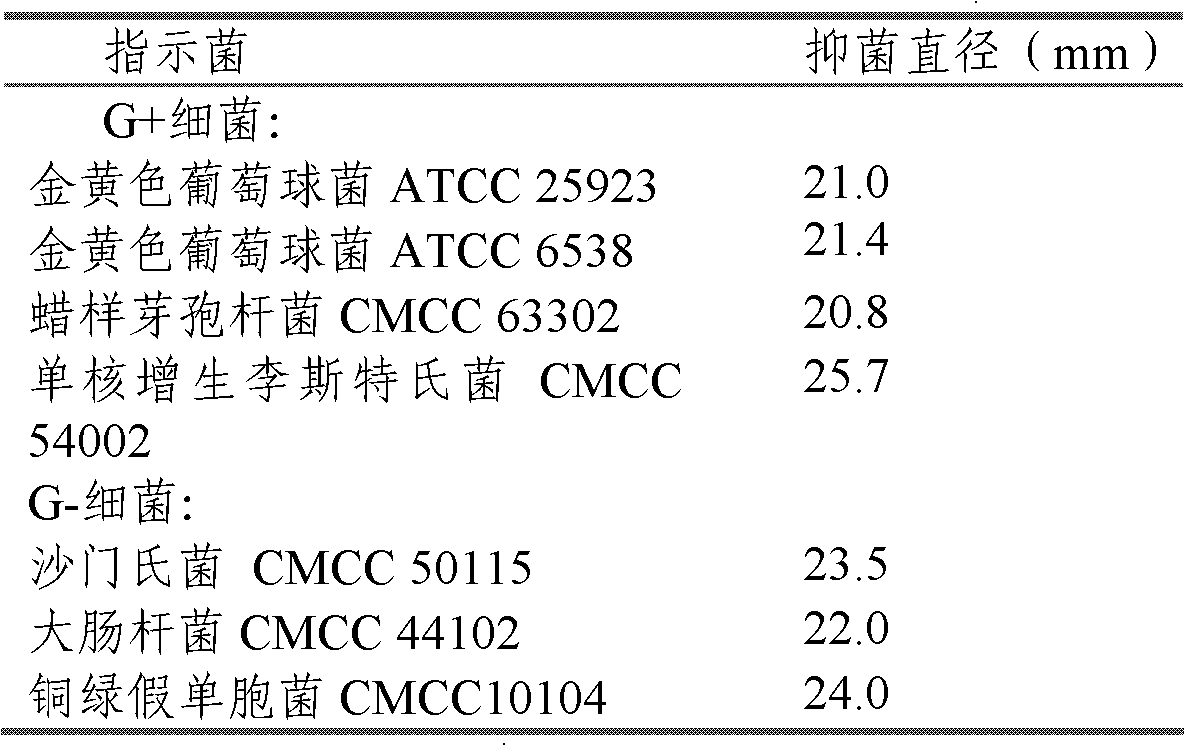

[0035] Antimicrobial peptides are extracted from the fermentation broth of Brevibacillus lateralosporus AS1.2739 to obtain food-grade antimicrobial peptide products. The steps are as follows:

[0036] (1) Bactericidal release of antimicrobial peptides: adjust the pH of the antimicrobial peptide fermentation broth produced by Brevibacillus lateralosporus fermentation to 3, heat at 121°C for 15min, add 2% NaCl by mass percentage, kill bacteria, inactivate protease, Precipitate impurities and completely release antimicrobial peptides from the cells into the fermentation broth;

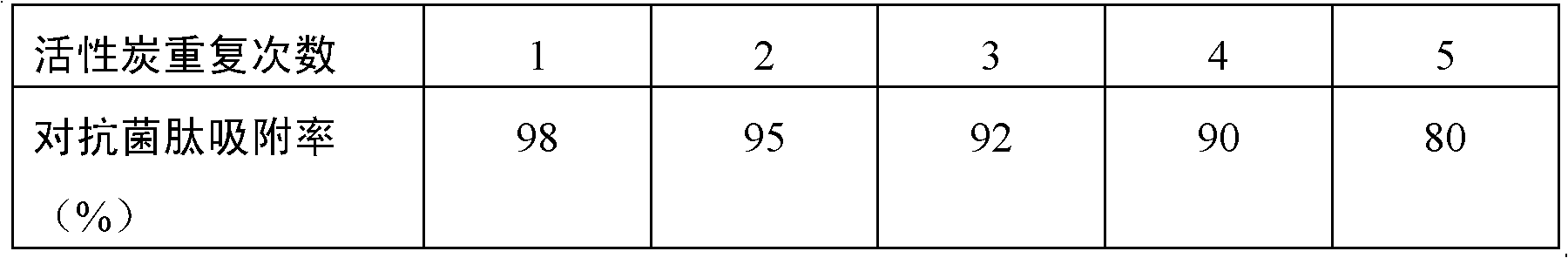

[0037] (2) Activated carbon adsorption: Add 1% activated carbon of the fermentation broth volume at 30°C for adsorption, stir at 100r / min for 10min, and make a complex of activated carbon-antibacterial peptide;

[0038] (3) Ethanol desorption: wash the precipitation of the activated carbon-antimicrobial peptide complex with distilled water twice, then desorb with absolute ethanol with 20% of the volume of...

Embodiment 2

[0044] Antimicrobial peptides were extracted from the fermentation broth of Brevibacillus lateralosporus AS1.2738 to obtain food-grade antimicrobial peptide products. The specific steps are as follows:

[0045] (1) Bactericidal release of antimicrobial peptides: adjust the pH of the antimicrobial peptide fermentation broth produced by Brevibacillus lateralsporosa to 6 with acid, heat at 121°C for 30 minutes, add 3% NaCl, kill bacteria, inactivate proteases, and precipitate foreign proteins , and the antimicrobial peptides are completely released from the bacteria into the fermentation broth;

[0046] (2) Activated carbon adsorption: add 5% activated carbon in the fermentation broth volume at 45°C for adsorption, stir at 200r / min for 5min, and make a complex of activated carbon-antibacterial peptide;

[0047] (3) Ethanol desorption: wash the precipitate of the activated carbon-antimicrobial peptide complex twice, then use 100% ethanol (95% ethanol concentration) in the volume o...

Embodiment 3

[0053] Antimicrobial peptides were extracted from the fermentation broth of Brevibacillus lateralosporus AS1.864 to obtain food-grade antimicrobial peptide products. The steps are as follows:

[0054] (1) Bactericidal release of antimicrobial peptides: adjust the pH of the antimicrobial peptide fermentation broth produced by Brevibacillus lateralosporus to 5 with acid, heat at 121°C for 20 minutes, add 2.5% NaCl, kill bacteria, inactivate proteases, and precipitate miscellaneous proteins , and the antimicrobial peptides are completely released from the bacteria into the fermentation broth;

[0055] (2) Activated carbon adsorption: add activated carbon with 2.5% of the fermentation broth volume at 40°C for adsorption, stir at 150r / min for 8min, and make a complex of activated carbon-antibacterial peptide;

[0056] (3) Ethanol desorption: the precipitation of the activated carbon-antimicrobial peptide complex was washed twice, and then desorbed with 60% ethanol (ethanol concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com