Method for preparing nitrogen-doped bismuth tungstate powder photocatalyst through microwave hydrothermal method

A microwave hydrothermal method and photocatalyst technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problem of low utilization of sunlight, low photocatalytic activity, small specific surface area, etc. problem, to achieve the effect of no hysteresis effect, high photocatalytic activity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

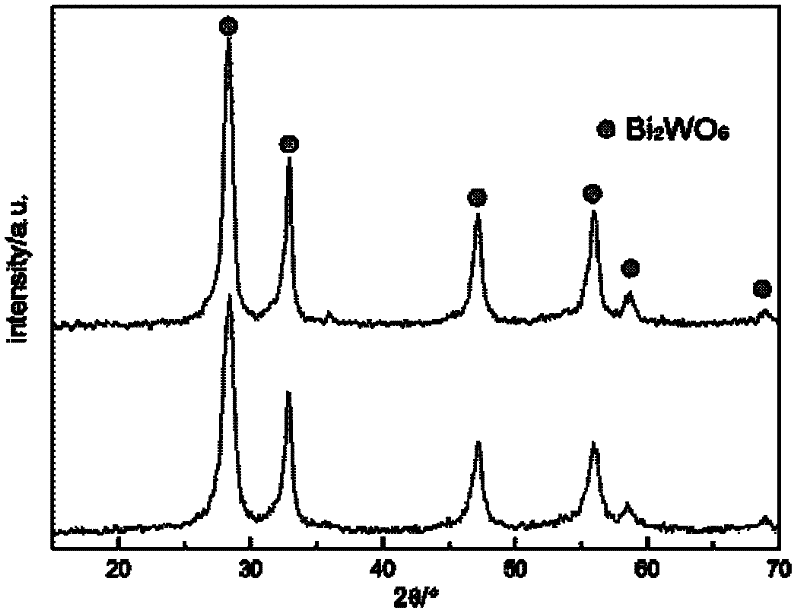

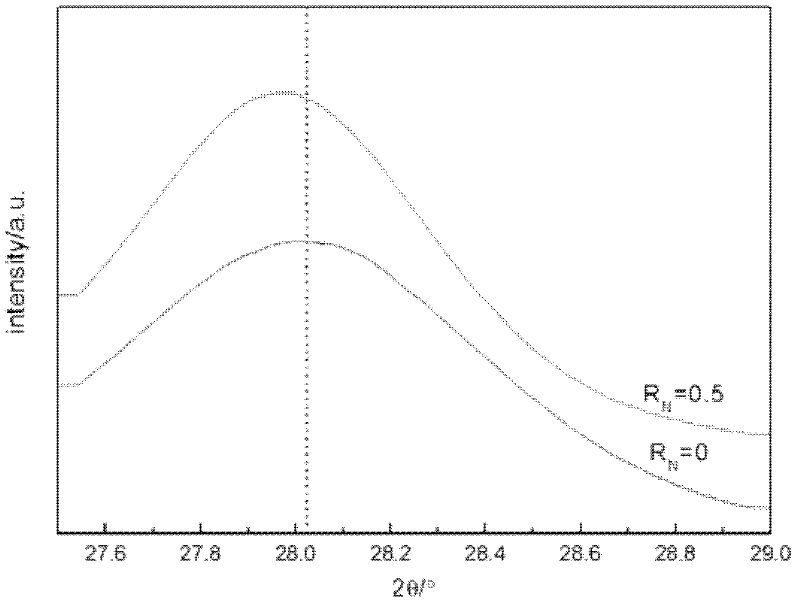

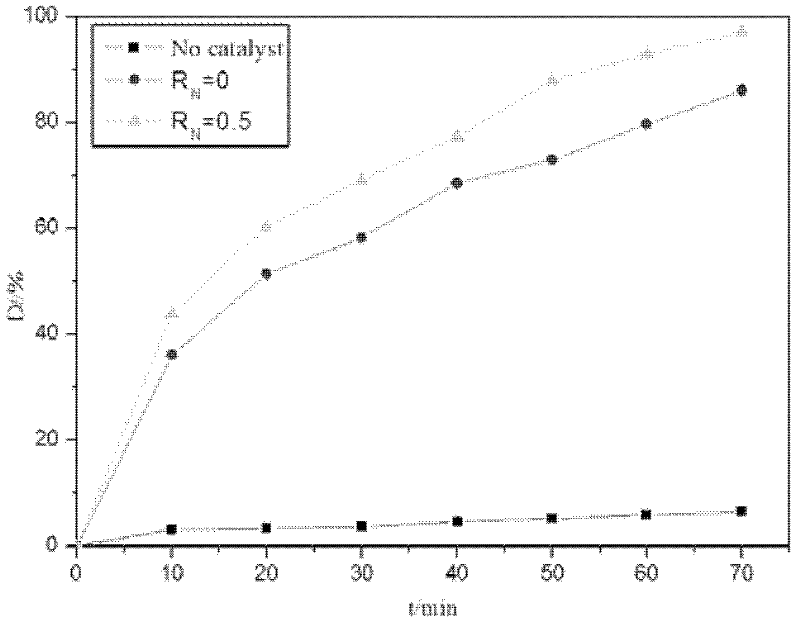

[0023] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O, Na 2 WO 4 2H 2 O and CO(NH 2 ) 2 Put it into a beaker, add an appropriate amount of deionized water to the beaker, in which Bi(NO 3 ) 3 Concentration is 0.05mol / L, Na 2 WO 4 The concentration is 0.025mol / L, R N for: R N =0(R N is the molar ratio of N to Bi), fully stirred until a white precipitate is produced, put the container containing the white precipitate into the ultrasonic instrument for 30mins, the precipitation reaction is complete, and the precursor solution of the microwave hydrothermal reaction is obtained;

[0024] Step 2: Put the precursor solution obtained in step 1 into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor MDS-8, set the power to 400w, and set the temperature at 180°C Stop reaction after reacting 60 minutes;

[0025] Step 3: After cooling down to room temperature, take out the precipitate in the reaction kettle, wash the precipitate with water ...

Embodiment 2

[0027] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O, Na 2 WO 4 2H 2 O and CO(NH 2 ) 2 Put it into a beaker, add an appropriate amount of deionized water to the beaker, in which Bi(NO 3 ) 3 The concentration is 0.1mol / L, Na 2 WO 4 Concentration is 0.05mol / L, R N for R N =2(R N is the molar ratio of N to Bi), fully stirred until a white precipitate is produced, put the container containing the white precipitate into an ultrasonic instrument for 30mins, the precipitation reaction is complete, and the precursor solution of the microwave hydrothermal reaction is obtained;

[0028] Step 2: Put the precursor solution obtained in step 1 into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor MDS-8, set the power to 500w, and set the temperature at 200°C Stop reaction after 30 minutes of reaction;

[0029] Step 3: After cooling down to room temperature, take out the precipitate in the reaction kettle, wash the precipitate with water a...

Embodiment 3

[0031] Step 1: Weigh Bi(NO 3 ) 3 ·5H 2 O, Na 2 WO 4 2H 2 O and CO(NH 2 ) 2 Put it into a beaker, add an appropriate amount of deionized water to the beaker, in which Bi(NO 3 ) 3 Concentration is 0.04mol / L, Na 2 WO 4 The concentration is 0.02mol / L, RN for R N =0.8(R N is the molar ratio of N to Bi), fully stirred until a white precipitate is produced, put the container containing the white precipitate into an ultrasonic instrument for 10 mins, and the precipitation reaction is complete, and the precursor solution of the microwave hydrothermal reaction is obtained;

[0032] Step 2: Put the precursor solution obtained in step 1 into a polytetrafluoroethylene-lined reactor, then put the reactor into a microwave hydrothermal reactor MDS-8, set the power at 350w, and set the temperature at 200°C Stop reaction after 40 minutes of reaction;

[0033] Step 3: After cooling down to room temperature, take out the precipitate in the reaction kettle, wash the precipitate with w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com