Light-metal and high-capacity composite hydrogen storage material and preparation method thereof

A hydrogen storage material and high-capacity technology, which is applied in the production of various metal hydrides and hydrogen, can solve the problems of inability to adapt to large-scale application of industrial production, reduced kinetic performance of hydrogen desorption, and lack of hydrogen storage capacity. Achieve good hydrogen desorption kinetic performance and reversible hydrogen storage performance, improve hydrogen desorption performance, and improve catalytic hydrogen storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

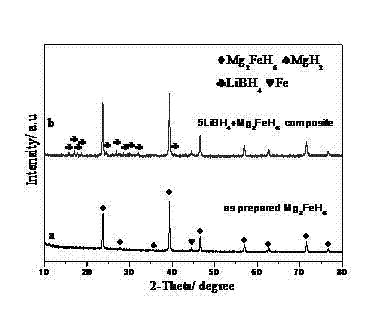

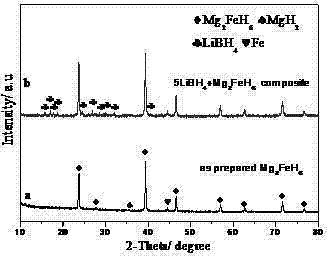

[0024] LiBH used 4 , Mg and Fe raw materials are commercial materials; according to the chemical formula Mg 2 FeH 6 , Weigh 2.5g of mixed powder with a molar ratio of Mg and Fe of 2:1, put it into a ball mill tank filled with 2MPa hydrogen (≥99.99%) and pre-mill it for 20h; then place the powder in an autoclave, the temperature from room temperature to 500 o C, the holding time is 30h, the initial hydrogen pressure is 12MPa; then LiBH 4 The powder and the above-mentioned hydrogenated powder were evenly mixed according to the molar ratio of 5:1, and then reacted with ball milling under 1MPa hydrogen (≥99.99%) for 2 hours to finally prepare 5LiBH 4 +Mg 2 FeH 6 Composite hydrogen storage materials.

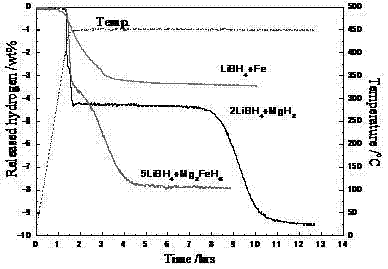

[0025] The hydrogen storage and desorption properties of the prepared composite hydrogen storage materials were measured by "constant volume-pressure difference method". Its dehydrogenation condition is: from room temperature to 450 o C, then 450 o C insulation, 4bar initia...

Embodiment 2

[0029] LiBH used 4 , Mg and Co raw materials are commercial materials; according to the chemical formula Mg 2 CoH 5 , Weigh 2.5g of mixed powder with a molar ratio of Mg and Co of 2:1, put it into a ball mill tank filled with 2.5MPa hydrogen (≥99.99%) and pre-mill it for 30h; then place the powder in an autoclave, Temperature rises from room temperature to 500 o C, the holding time is 48h, the initial hydrogen pressure is 10MPa; then LiBH 4 The powder and the above-mentioned hydrogenated powder were evenly mixed according to the molar ratio of 4.5:1, and then reacted and ball-milled for 2 hours under 1MPa hydrogen (≥99.99%) to finally prepare 4.5LiBH 4 +Mg 2 CoH 5 Composite hydrogen storage materials.

[0030] Table 1 shows the hydrogen storage capacity of different composite systems. As shown in Table 1, although the theoretical hydrogen storage capacity of the composite system containing Fe and Co has decreased, it is still much higher than the 6.0 wt% proposed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com