Preparation method of hydrogen storage material of borane ammonia compound

A technology for hydrogen storage materials and compounds, applied in chemical instruments and methods, hydrogen production, metal hydrides, etc., can solve the problems of low sample purity, complicated preparation process, and low synthesis yield, and achieve non-toxic raw materials and methods The effect of simple and easy operation and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

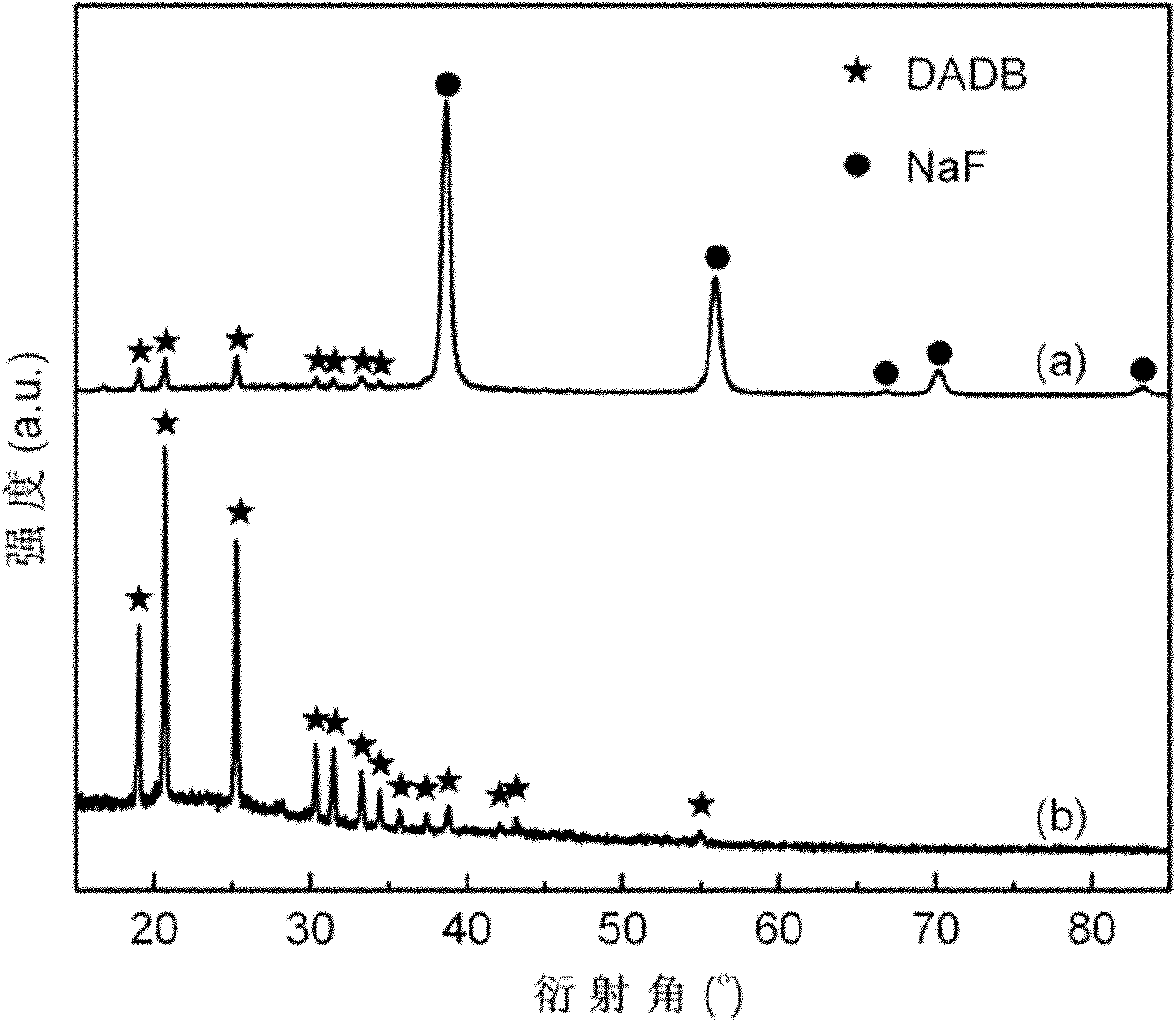

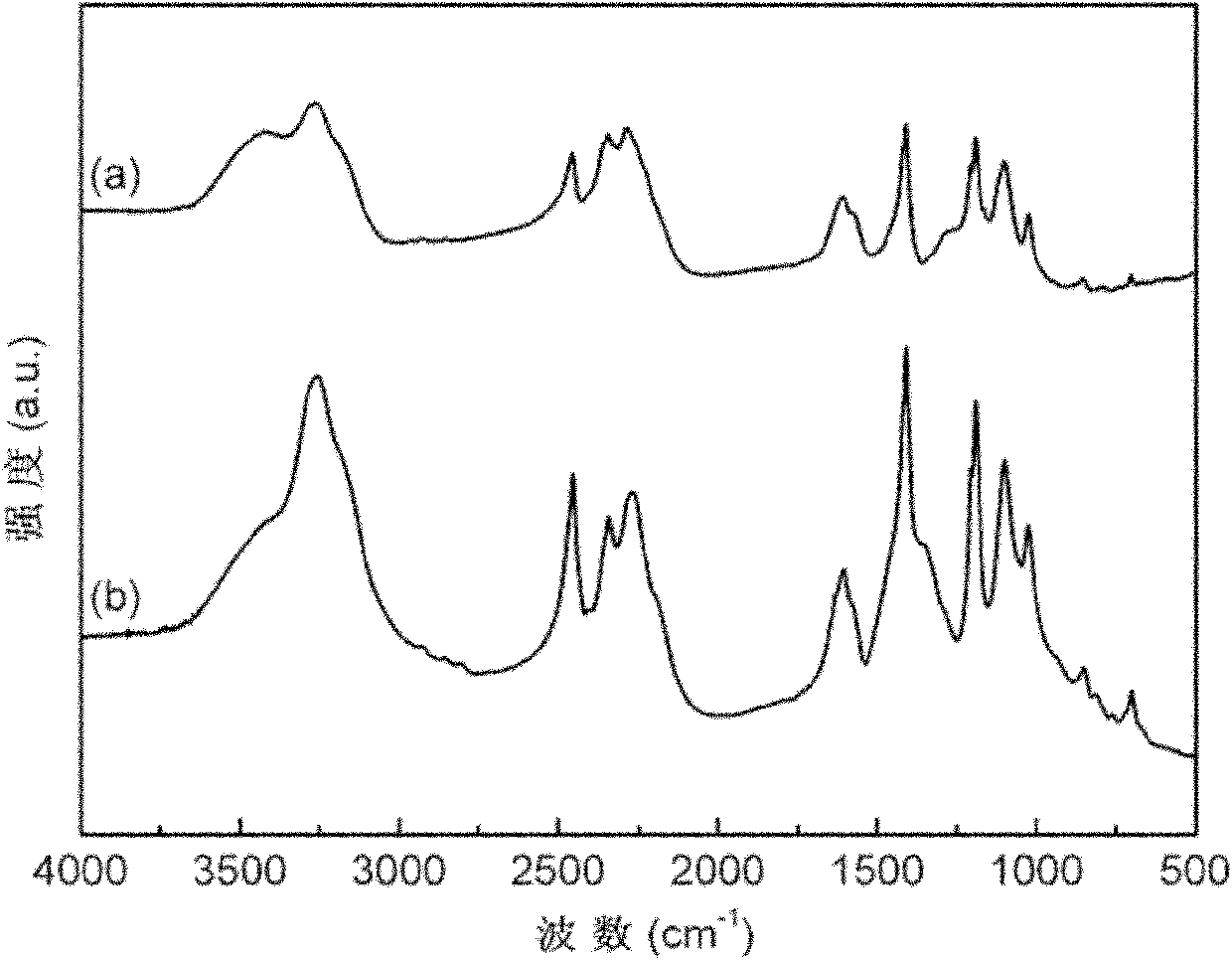

[0020] NaBH 4 and NH 4 F is the starting material, the molar ratio is 1:1, and the mixture of DADB / 2NaF is prepared by mechanical ball milling method; then the by-product NaF in the ball milled sample is removed by dissolving, filtering, deammonizing and other steps with liquid ammonia as solvent, A white DADB powder was obtained as follows:

[0021] The raw material used is: NaBH 4 (purity 98%, ~200 mesh), NH 4 F (purity 98%, ~200 mesh).

[0022] NaBH in an argon atmosphere glove box 4 / NH 4 The F mixture and stainless steel balls were put into a stainless steel ball mill jar, sealed with a cover and placed on a Fritsch 7 planetary ball mill for 3 hours. The ball milling atmosphere is high-purity argon (purity 99.9999%), the initial pressure is 1 atmosphere, and the mass ratio of balls to materials is about 100:1. Put the ball-milled sample into a three-necked round-bottomed flask filled with liquid ammonia solvent, stir ultrasonically for 30 minutes, then let it stand...

Embodiment 2

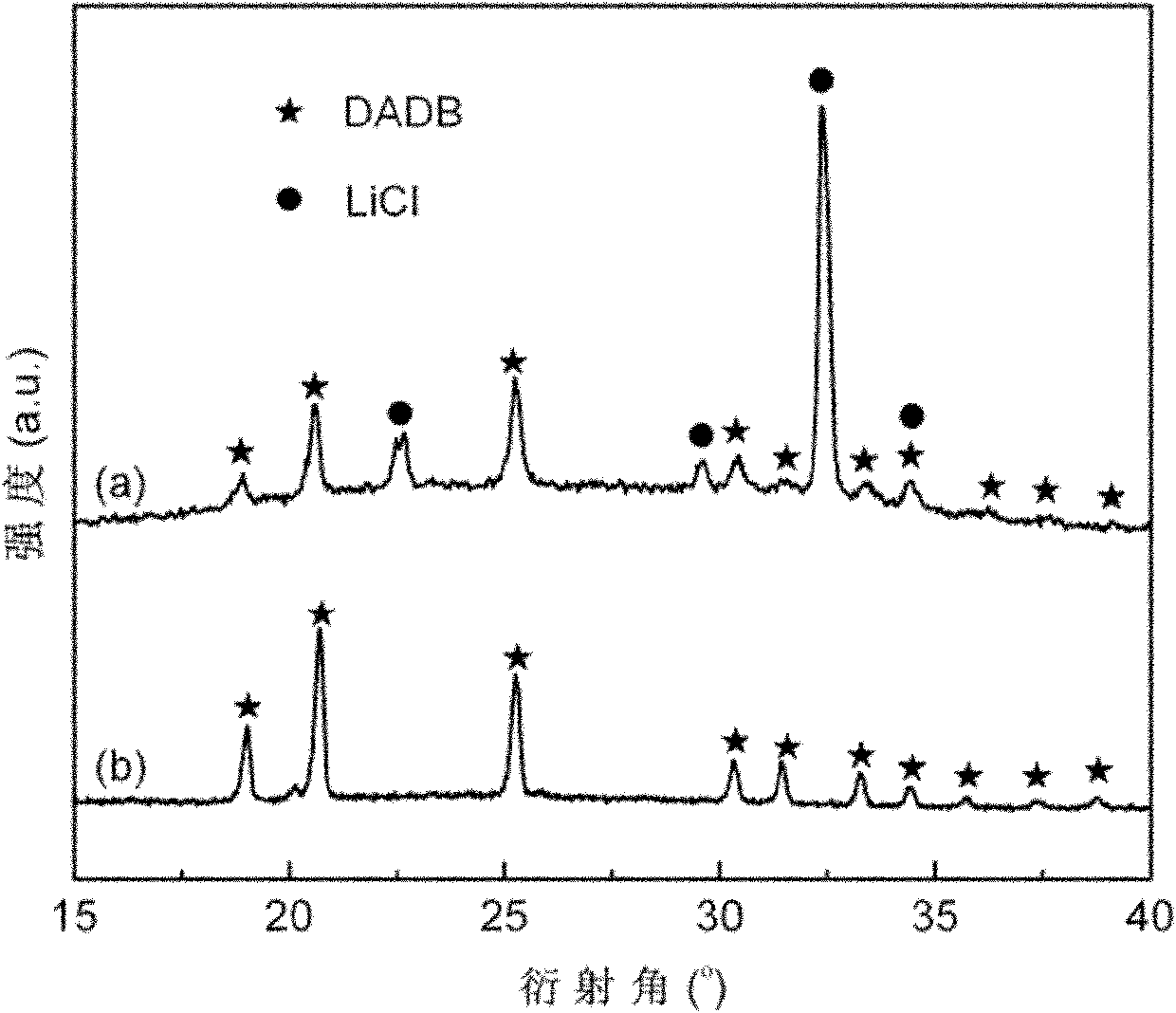

[0026] Take LiBH 4 and NH 4 Cl is the starting material, the molar ratio is 1:1, the ball milling time is 1 hour, and the rest of the preparation conditions are the same as in Example 1.

[0027] The raw material used is: LiBH 4 (purity 98%, ~200 mesh), NH 4 Cl (purity 98%, ~200 mesh).

[0028] X-ray diffraction test conditions are the same as in Example 1. image 3 gives (a) LiBH 4 / NH 4 X-ray diffraction pattern of Cl ball-milled sample and (b) DADB after purification. The results showed that LiBH 4 / NH 4 The Cl mixture reacts completely according to the stoichiometric ratio during the ball milling process to form a mixture of DADB and LiCl, the X-ray diffraction pattern of DADB and the results reported in the literature [1.S.G.Shore and K.W. Inorg.Chem.1964, 3, 914-915] consistent; the liquid ammonia purification method can effectively remove the by-product LiCl, and finally obtain a white DADB powder sample with a particle size of about 300 mesh, a purity of ≥98%...

Embodiment 3

[0031] Take LiBH 4 and (NH 4 ) 2 SO 4 as the starting material, the molar ratio is 2:1, the ball milling time is 2 hours, and the rest of the preparation conditions are the same as in Example 1.

[0032] The raw material used is: LiBH 4 (purity 98%, ~200 mesh), (NH 4 ) 2 SO 4 (purity 98%, ~200 mesh).

[0033] X-ray diffraction test conditions are the same as in Example 1. Figure 5 gives (a)2LiBH 4 / (NH 4 ) 2 SO 4 The X-ray diffraction pattern of the ball-milled sample and (b) DADB after purification. The results showed that 2LiBH 4 / (NH 4 ) 2 SO 4 During the ball milling process, the mixture reacted completely according to the stoichiometric ratio to form DADB and Li 2 SO 4 The mixture, the X-ray diffraction pattern of DADB and the results reported in the literature [1.S.G.Shore and K.W. Inorg.Chem.1964,3,914-915] consistent; adopting the liquid ammonia purification method can effectively remove the by-product Li 2 SO 4 , finally obtained a white DADB po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com